Hydrothermal or pyrohydrolysis tail gas resource utilization system and hydrothermal or pyrohydrolysis tail gas resource utilization method

A technology of resource utilization and thermal hydrolysis, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as tail gas odor, achieve convenient management, save investment, and reduce land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

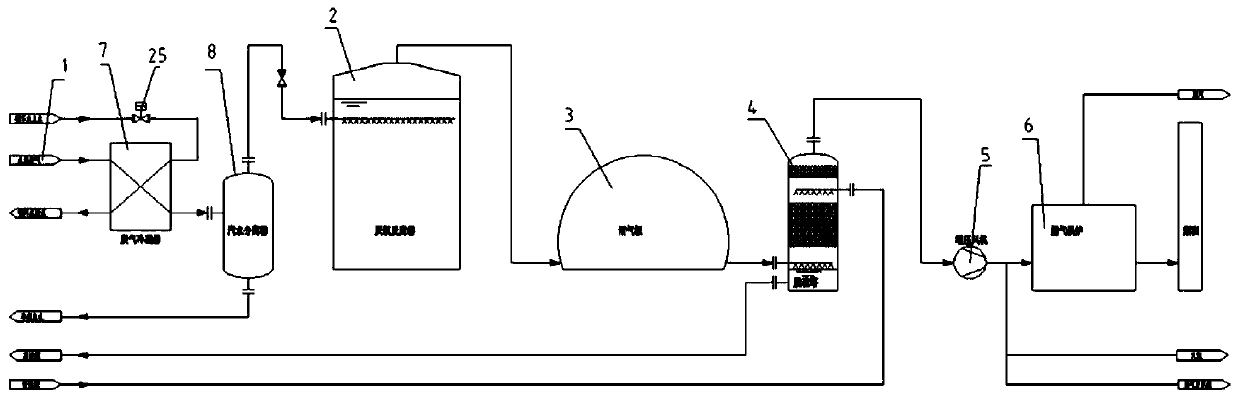

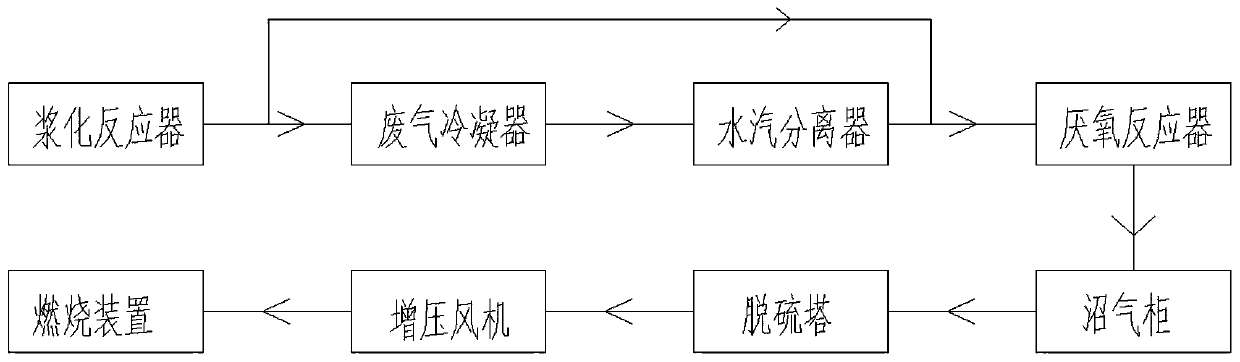

[0046] Such as figure 1 and 5 As shown, a hydrothermal or thermal hydrolysis tail gas resource utilization system includes a slurry reactor 1, an anaerobic reactor 2, a biogas tank 3 and a desulfurization tower 4; the slurry reactor 1 and anaerobic reactor 2 communicated, the anaerobic reactor 2 is communicated with the biogas cabinet 3; the biogas cabinet 3 is communicated with the desulfurization tower 4; it also includes a booster fan 5 and a combustion device 6; the gas inlet of the booster fan 5 is connected with the desulfurization tower The gas outlet of 4 is connected through through, and a check valve is provided between the gas inlet of the booster fan 5 and the gas outlet of the desulfurization tower 4, and the booster fan 5 is connected with the combustion device 6 .

[0047] The desulfurization tower 4 is a wet desulfurization tower, and the desulfurizing agent of the desulfurization tower is sodium carbonate, which comes from the lean liquid tank, and the rich l...

Embodiment 2

[0057] Such as figure 1 and 5 As shown, a hydrothermal or thermal hydrolysis tail gas resource utilization system includes a slurry reactor 1, an anaerobic reactor 2, a biogas tank 3 and a desulfurization tower 4; the slurry reactor 1 and anaerobic reactor 2, the anaerobic reactor 2 communicates with the biogas tank 3; the biogas tank 3 communicates with the desulfurization tower 4.

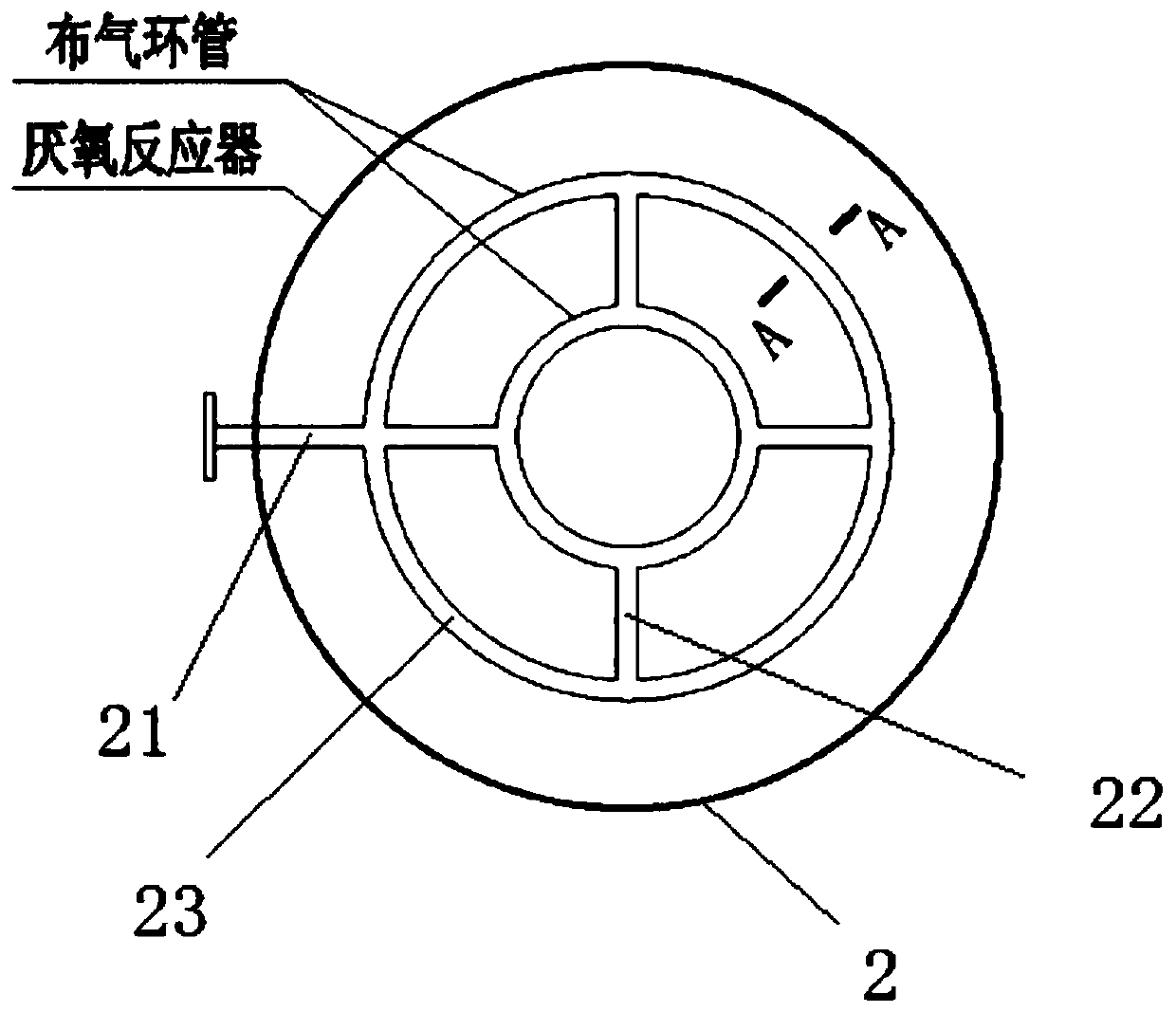

[0058] A waste gas condenser 7 and a steam-water separator 8 are arranged between the slurry reactor 1 and the anaerobic reactor 2; the waste gas outlet of the slurry reactor 1 is connected with the gas inlet of the waste gas condenser 7, and the waste gas condenser The gas outlet of 7 is connected with the gas inlet of anaerobic reactor 2, and a check valve is arranged between the gas outlet of exhaust gas condenser 7 and the gas inlet of anaerobic reactor 2, and the gas inlet of described anaerobic reactor 2 is low At the working liquid level of the anaerobic reactor 2; the water inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com