Polyurethane acrylic ester photosensitive resin oligomer and preparation method thereof

A polyurethane acrylate and photosensitive resin technology, applied in the material field, can solve the problems of easy yellowing and insufficient flexibility, and achieve the effects of solving yellowing, high resolution and high glass transition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

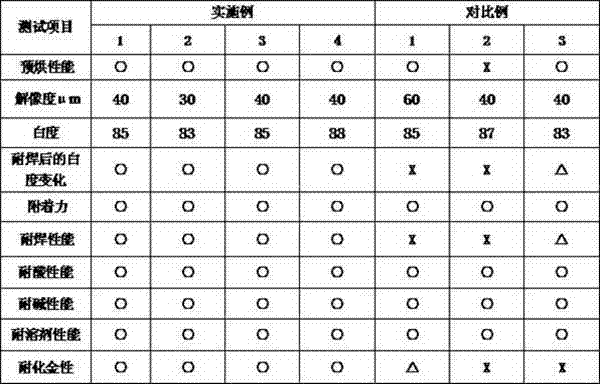

Image

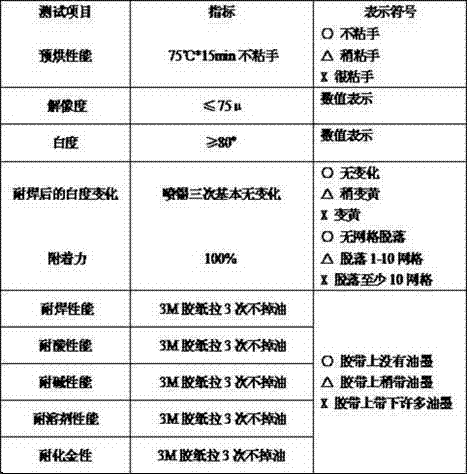

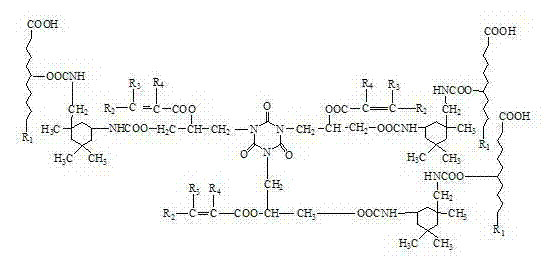

Examples

Embodiment 1

[0022] Add 312g of 3-methylene carbamic acid propionate-3,5,5-trimethylcyclohexyl isocyanate to 370g of tris(epoxypropyl)isocyanuric acid acrylate, with toluene as solvent, at 85°C The reaction was stirred for 5 hours. After the reaction was completed, the solvent was removed from the reaction mixture by vacuum distillation to obtain the final product, namely a urethane acrylate structure containing at least one carboxyl group and one triazine ring in one molecule.

Embodiment 2

[0024] Add 340g of 3-methylenecarbamic acid valerate-3,5,5-trimethylcyclohexyl isocyanate into 383g of three (epoxypropyl)isocyanuric acid methacrylate, with xylene as solvent, The reaction was stirred at 85°C for 5 hours. After the reaction was completed, the solvent was removed from the reaction mixture by vacuum distillation to obtain the final product, namely a urethane acrylate structure containing at least one carboxyl group and one triazine ring in one molecule.

Embodiment 3

[0026] 354g 3-methylene carbamic acid hexanoate-3,5,5-trimethylcyclohexyl isocyanate is added among 383g tris (epoxypropyl) isocyanuric acid methacrylate, with toluene as solvent, in The reaction was stirred at 85°C for 5 hours. After the reaction was completed, the solvent was removed from the reaction mixture by vacuum distillation to obtain the final product, namely a urethane acrylate structure containing at least one carboxyl group and one triazine ring in one molecule.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com