Injection molding machine and injection molding method adopting injection molding machine

An injection molding machine and an inert gas technology, which is applied in the field of injection molding machines to avoid yellowing of the light guide plate during the production process, can solve the problems of insignificant improvement effect and increased cost, and achieves the solution of the yellowing of the light guide plate and the high reliability. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

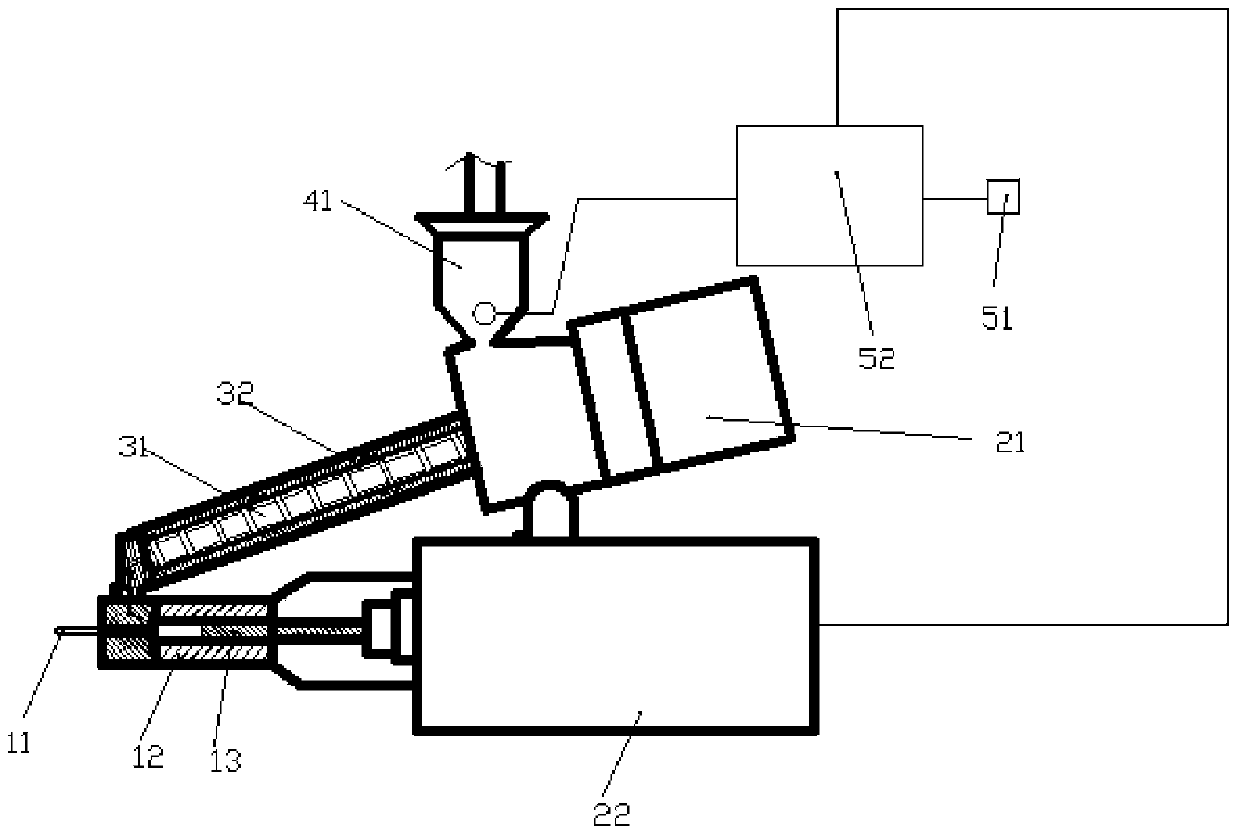

[0038] Such as figure 1 As shown, the inert gas generator in the first embodiment includes a nitrogen generator 52, one end of the nitrogen generator 52 is connected to the hopper 41, and the other end is connected to the driving device. The driving device controls the nitrogen generator 52 to be turned on to generate nitrogen, and the nitrogen generator 52 is connected with an air compressor 51 . The air is collected by the air compressor 51 and then the compressed gas produced is sent to the nitrogen generator 52 through the pipeline.

[0039] Such as Figure 4 As shown, the specific steps of using the injection molding machine provided in this embodiment to inject a non-yellowing light guide plate are as follows:

[0040] S1, the nitrogen generator 52 replaces the oxygen in the hopper 41 with nitrogen;

[0041] S2. After the oxygen in the hopper 41 is replaced by nitrogen, the screw 31 rotates to add materials to the barrel 32;

[0042]S3. The driving device drives the ...

Embodiment 2

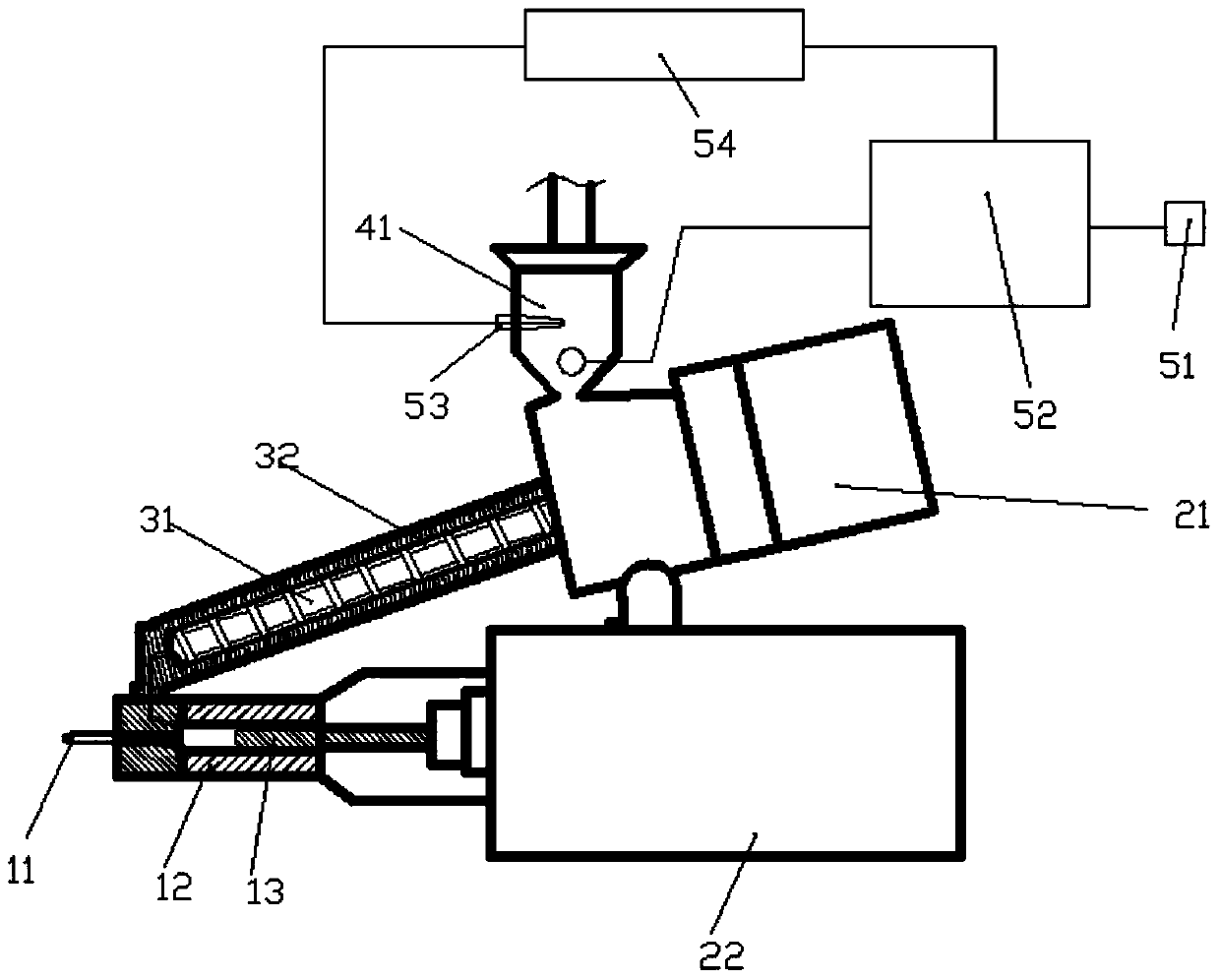

[0045] The structure of the injection molding machine provided in the second embodiment is basically the same as that in the first embodiment, and the similarities will not be repeated. The difference lies in the inert gas generator.

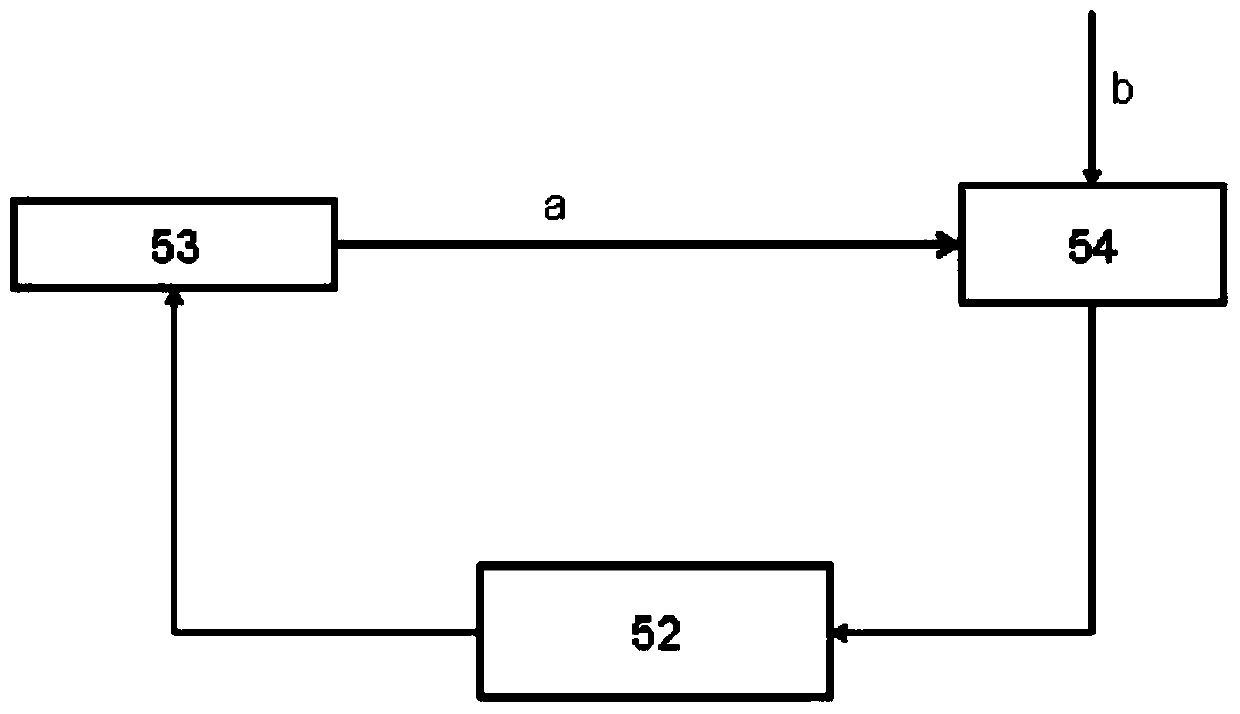

[0046] Such as figure 2 As shown, the inert gas generating device in the injection molding machine provided in the second embodiment includes a nitrogen generator 52, a detection probe 53 and a signal controller 54, the detection probe 53 is arranged in the hopper 41, and the detection probe 53 is electrically connected to the signal controller 54 , the signal controller 54 controls the opening and closing of the inert gas generator. The detection probe 53 is used to detect the oxygen in the hopper 41, and gives different signals according to the oxygen content, and transmits the signal to the signal controller 54 to analyze the received signal. When the oxygen content exceeds the set value, the signal is given. The signal induced by the nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com