Patents

Literature

61 results about "Inert gas generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inert gas generator (IGG) refers to machinery on board marine product tankers. Inert gas generators consist distinctively of a gas producer and a scrubbing system.

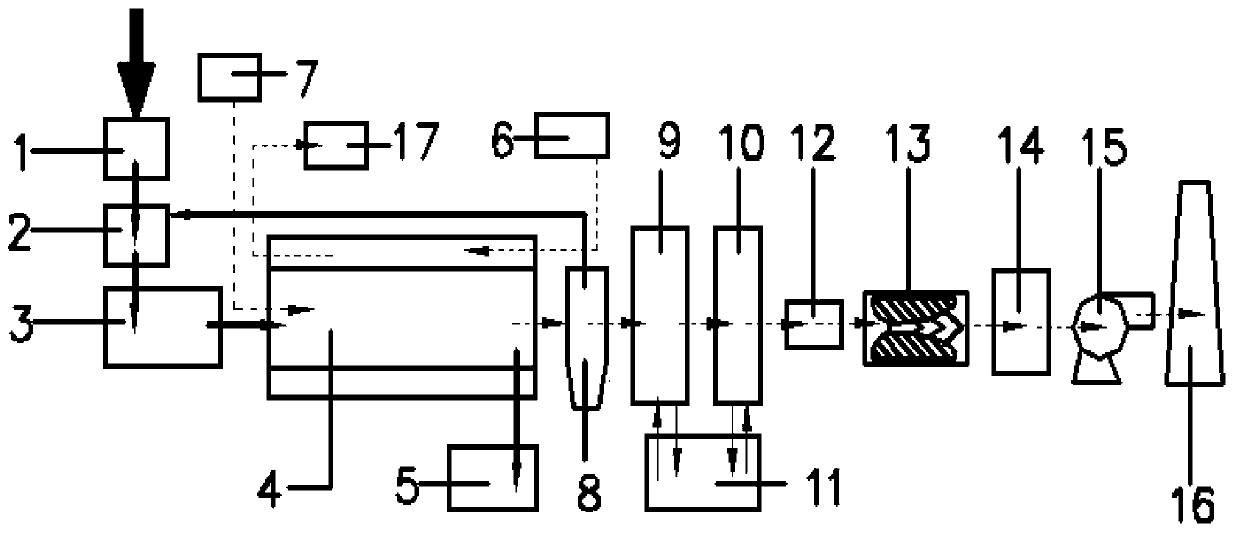

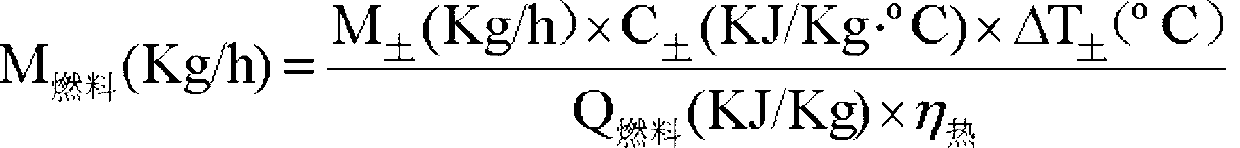

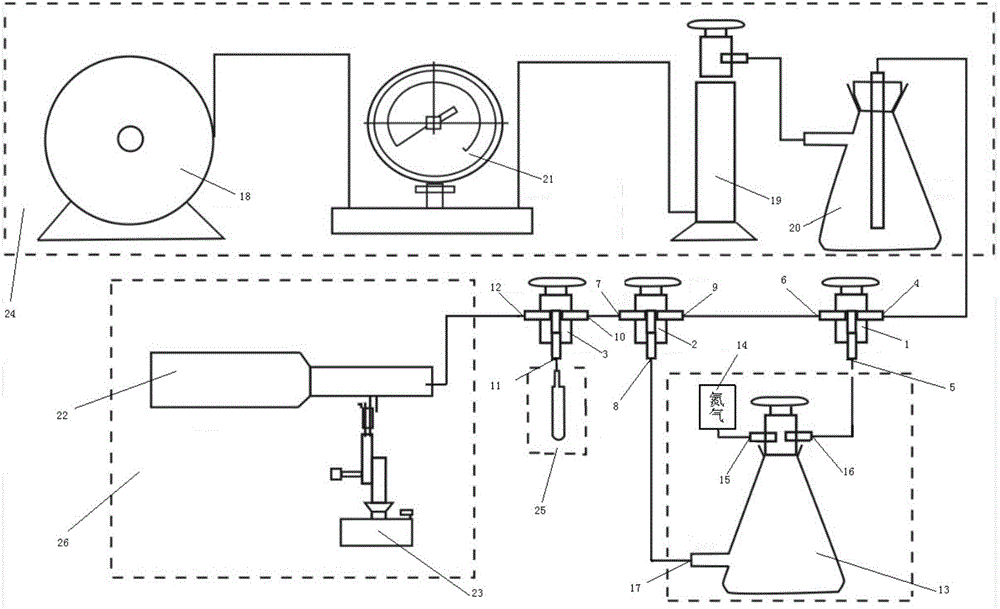

Method and device for repairing contaminated soil with persistent organic pollutants

ActiveCN103272838AAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

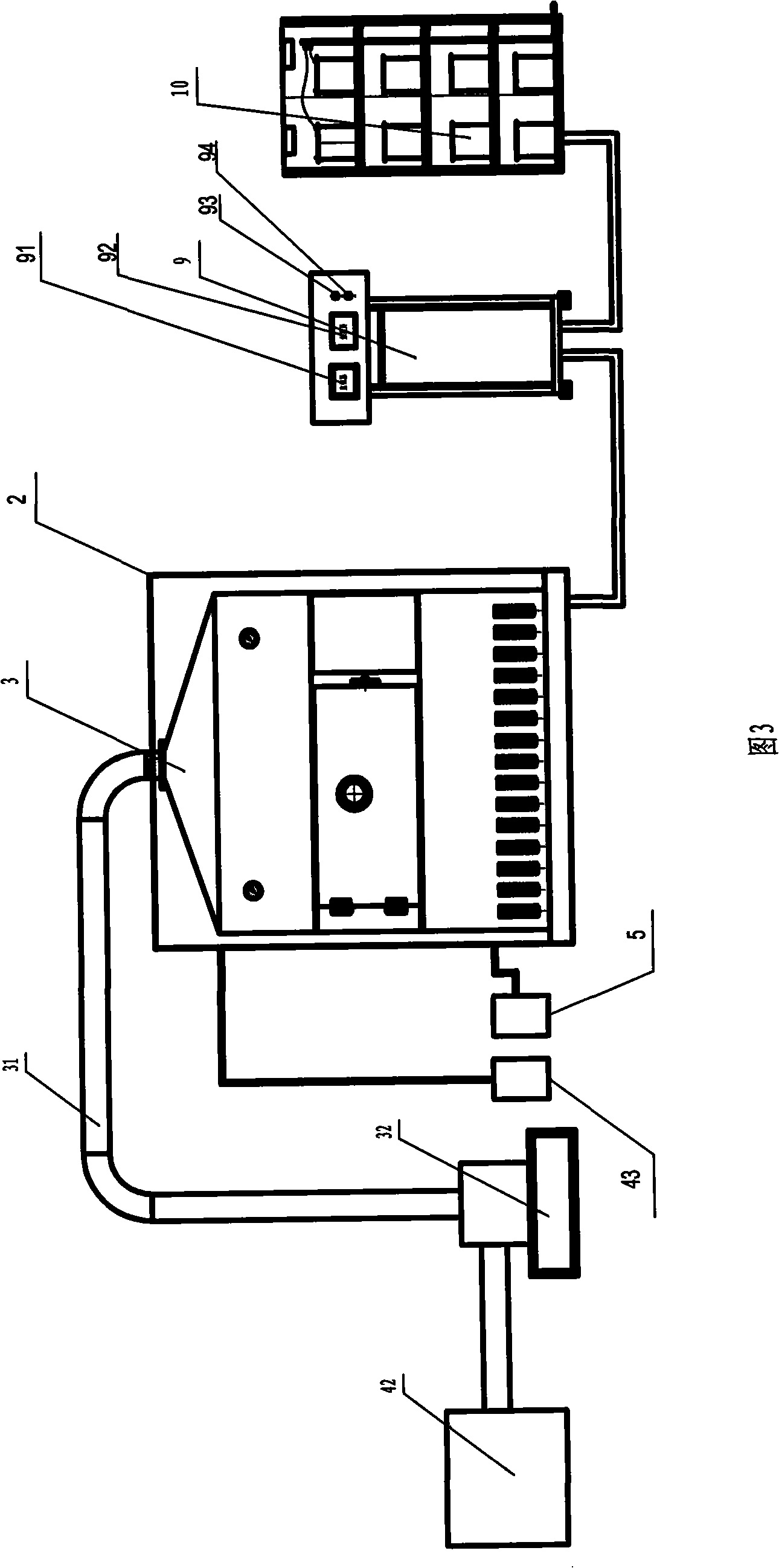

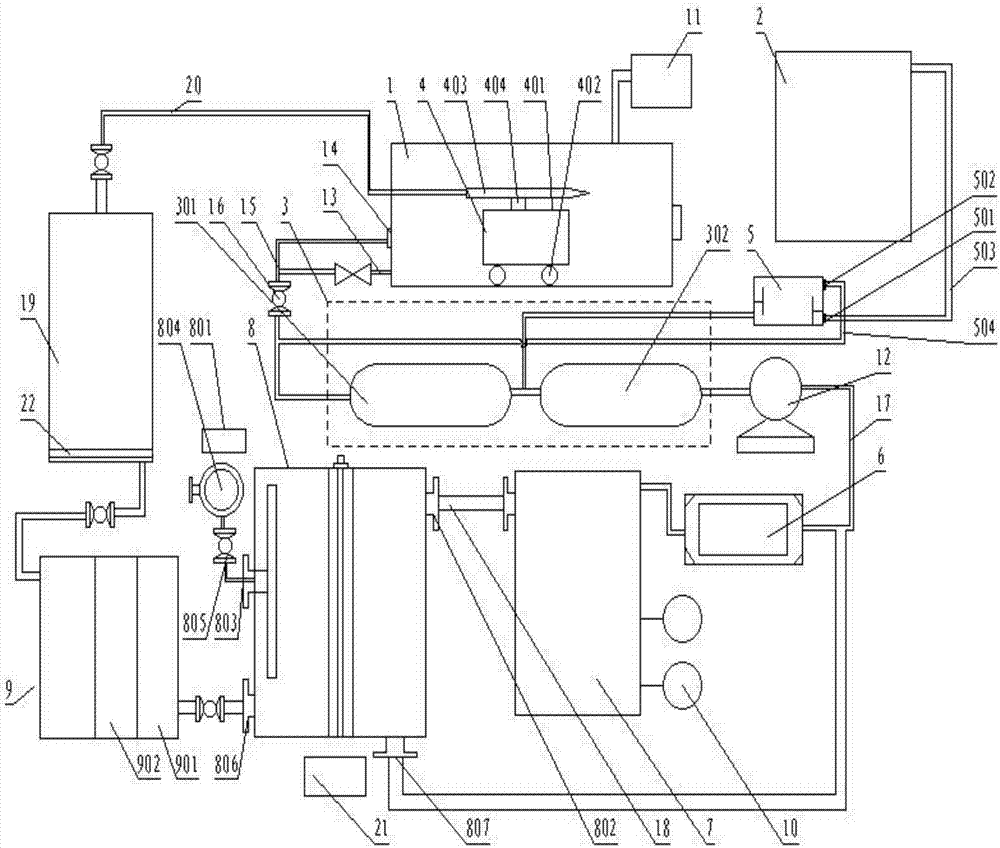

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

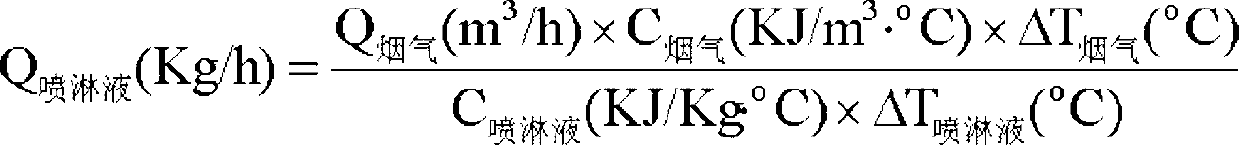

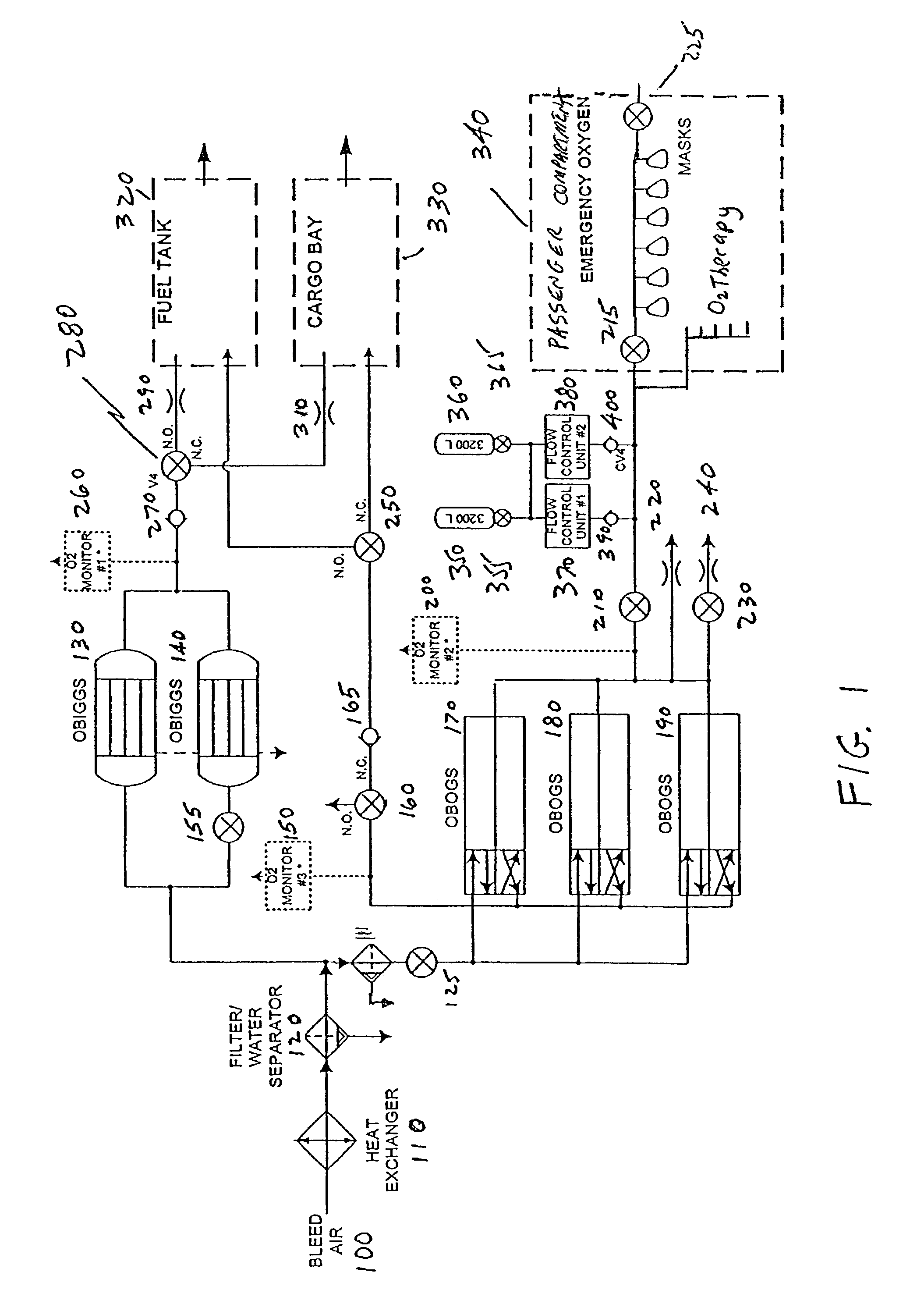

Oxygen/inert gas generator

InactiveUS6997970B2Capable be useDispersed particle filtrationAir-treatment apparatus arrangementsAtmospheric airOn board

A gas generation method and apparatus, capable of use in an aircraft, generates oxygen with at least one On Board Oxygen Generating System (OBOGS) and generates an inert gas with at least one On Board Inert Gas Generating System (OBIGGS) and selectively supplies an auxiliary supply of inert gas utilizing a waste gas output of the at least one OBOGS. The inert gas can include nitrogen. An auxiliary source of oxygen can also be provided. Control valves can be used to selectively supply the waste gas output of the at least one OBOGS to the atmosphere or to either of two locations. The oxygen can be used in a passenger compartment of the aircraft and the inert gas used in either a fuel tank or cargo bay of the aircraft.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

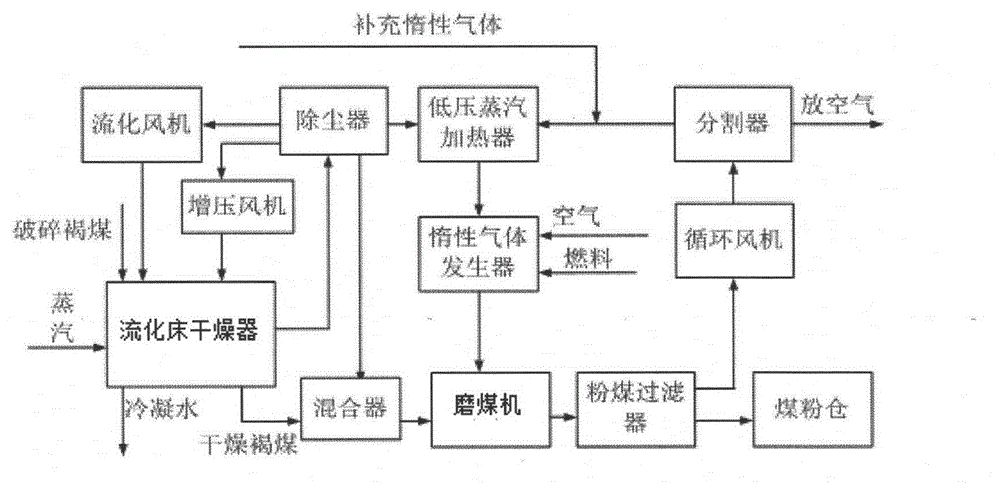

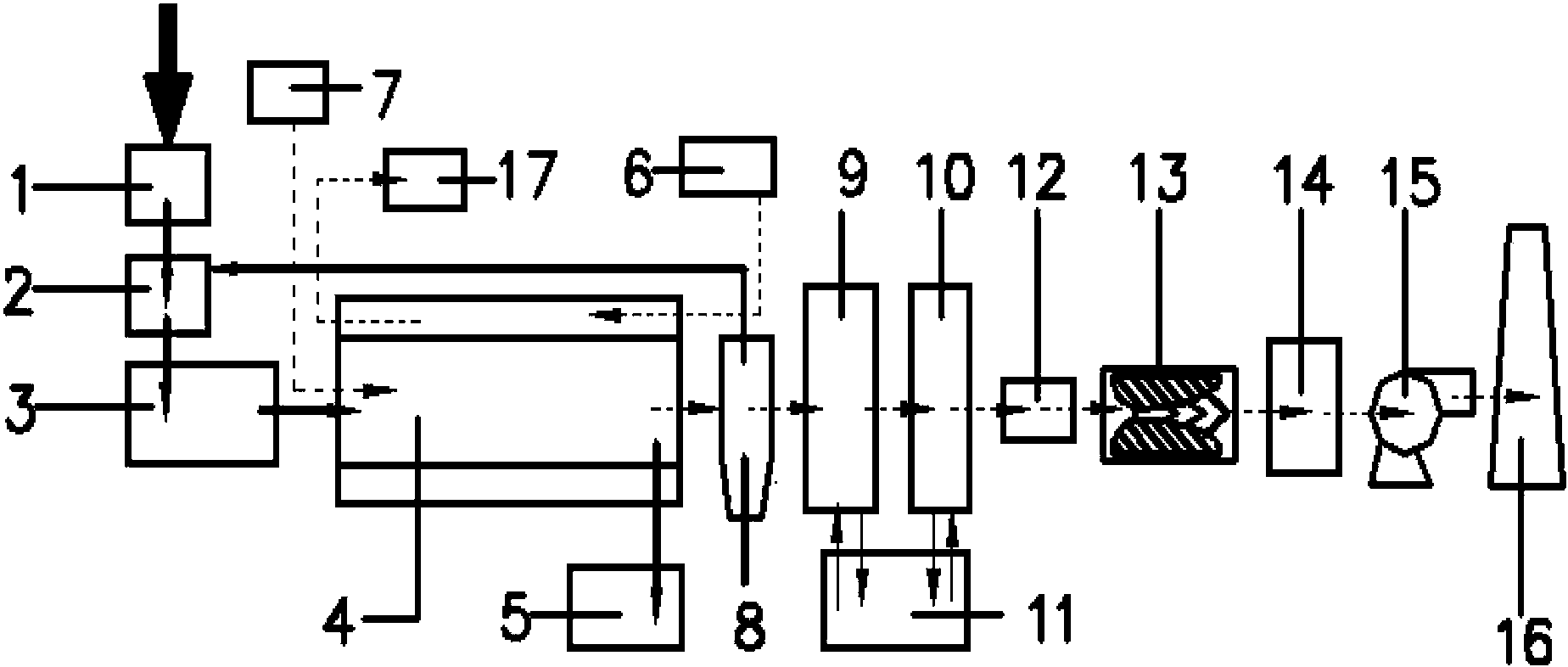

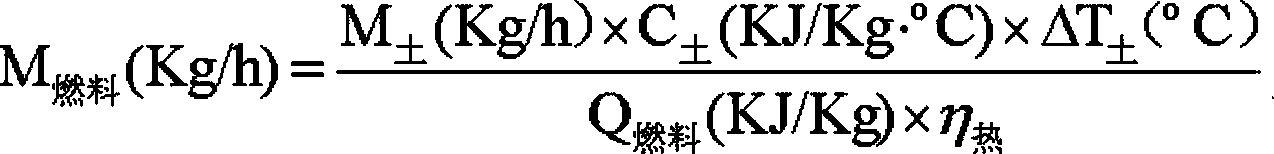

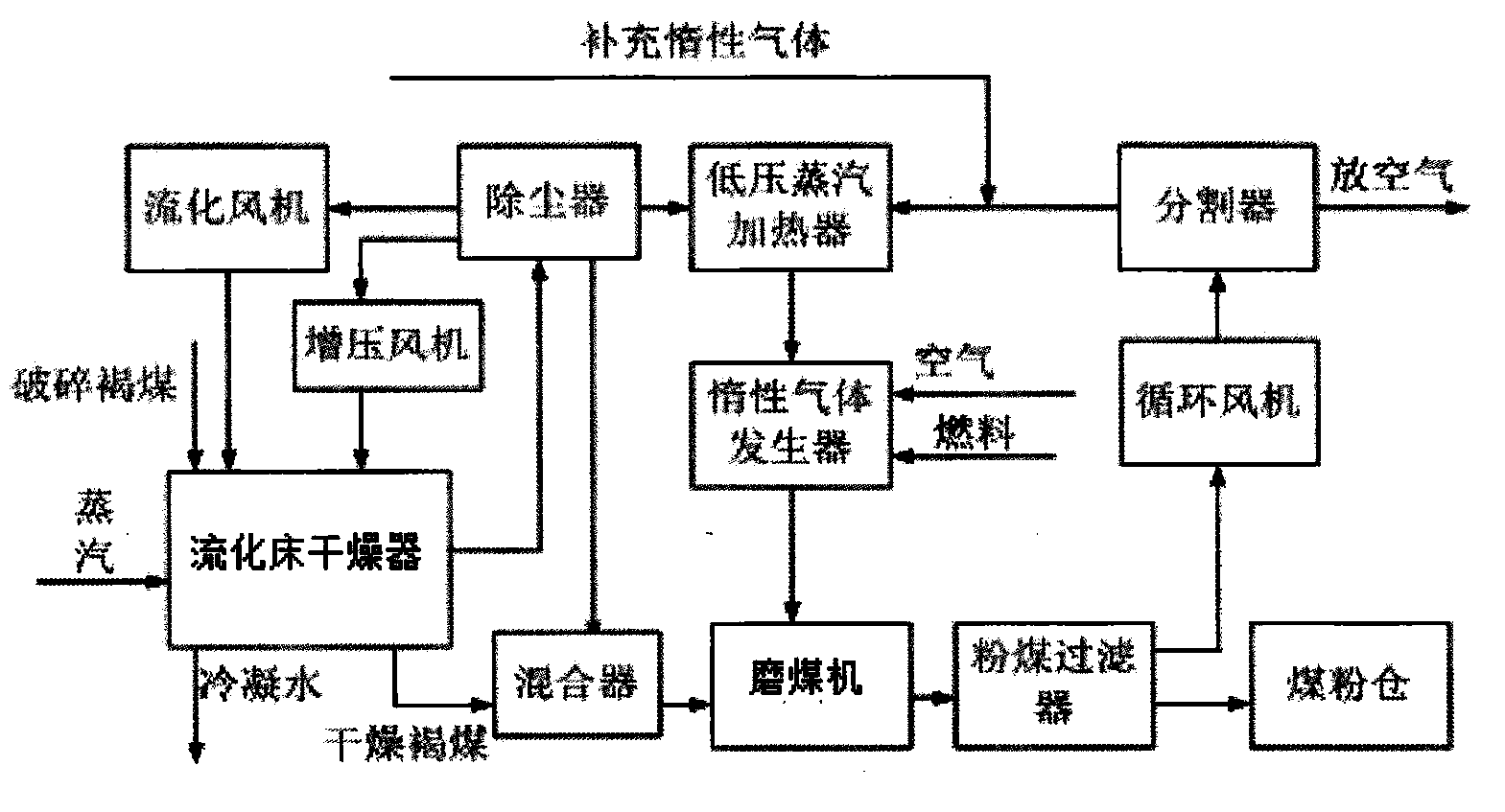

High-moisture brown coal pulverizing and drying apparatus and method thereof

ActiveCN103146454AImprove sealingImprove adaptabilityDrying solid materials with heatDrying gas arrangementsFluidized bed dryingBrown coal

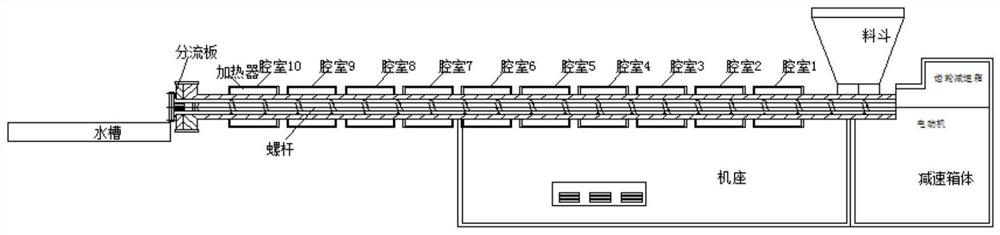

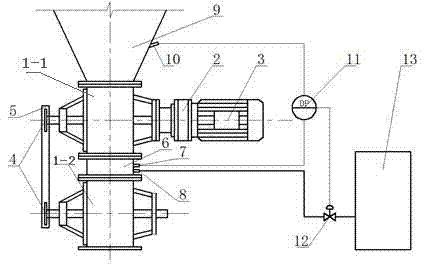

The invention provides a high-moisture brown coal pulverizing and drying apparatus and a method thereof. The brown coal pulverizing and drying apparatus is characterized in that the apparatus comprises a fluidized bed dryer, the fluidized bed dryer is connected with a deduster, the deduster is connected with the inlet of a mixer, the deduster is connected with a low pressure steam heater, a fluidization fan and a booster fan, the fluidization fan is connected with the fluidized bed dryer, the booster fan is connected with the steam coil tube of the fluidized bed dryer, the fluidized bed dryer is connected with the inlet of the mixer, the mixer is connected with a coal pulverizer, the coal pulverizer is connected with a pulverized coal filter, the pulverized coal outlet of the pulverized coal filter is connected with a pulverized coal cabin, the gas outlet of the pulverized coal filter is connected with a circulating fan, the circulating fan is connected with a divider, the divider is connected with the low pressure steam heater, the low pressure steam heater is connected with an inert gas generator, and the inert gas generator is connected with the coal pulverizer. The apparatus and the method are suitable for the drying and the pulverizing of coals comprising high-moisture brown coal and the like, and the particle size distribution and the water content of the prepared pulverized coal are adapted to requirements of a vaporizing furnace.

Owner:SHANGHAI BOILER WORKS

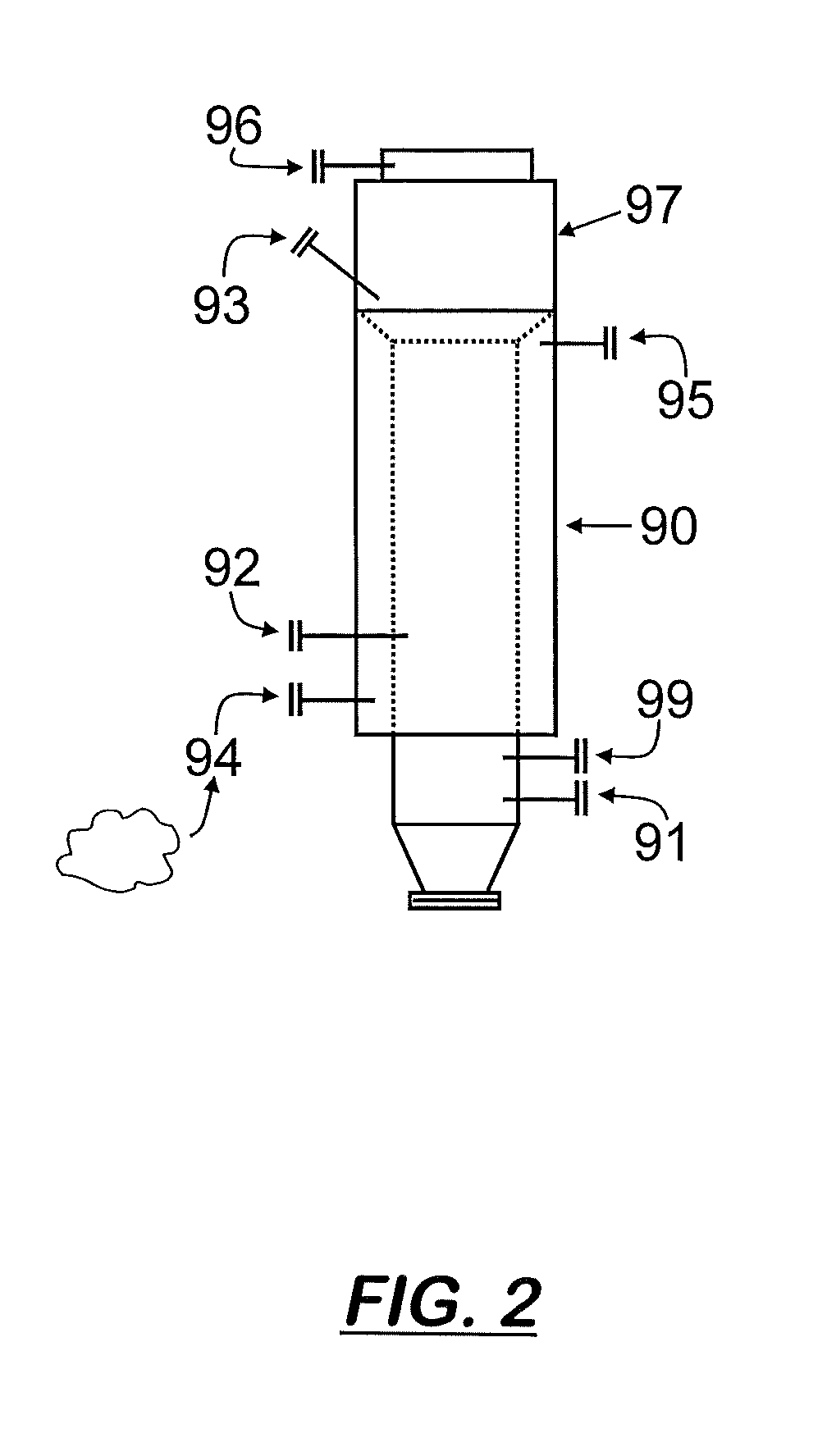

Self-regulating bio-gas treatment system

A self-regenerating bio-gas treatment system that uses the bio-gas instead of atmospheric are as media transport between adsorber and desorber tanks. Each tank includes at least four horizontally stacked and evenly spaced apart, perforated trays each capable being filled with fluidized carbon which migrates downward in the adsorber tank to remove contaminants from the bio-gas. With the bio-gas function as its media transport, the carbon media continuously moves downward over the perforated trays and eventually collected in the bottom of the adsorber tank. The spent carbon is then delivered to the desorber tank. The desorber tank is filled with an inert gas produced by an inert gas generator which causes the carbon media to be regenerated. The inert gas strips the carbon media of contaminates and is then delivered to a ground flare. The carbon media is returned to the adsorber tank and re-used to treat bio-gas. A plurality of heat exchangers, blowers, valves and interconnecting conduits keep the bio-gas, the inert gas, and the carbon media continuously flowing through the system thereby enabling the system to be used at different sizes of landfills or treatment plants.

Owner:SNAP ENERGY SYST

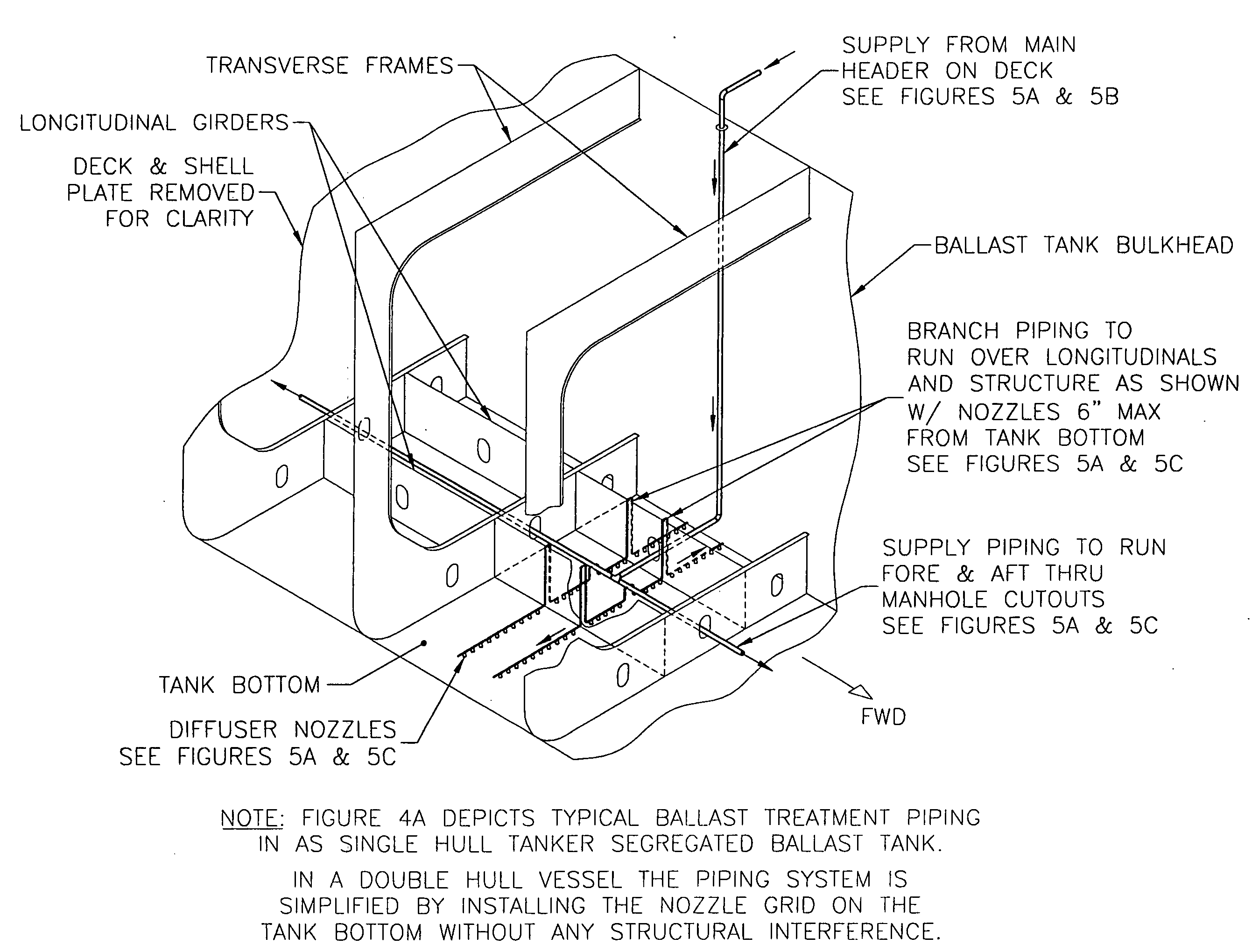

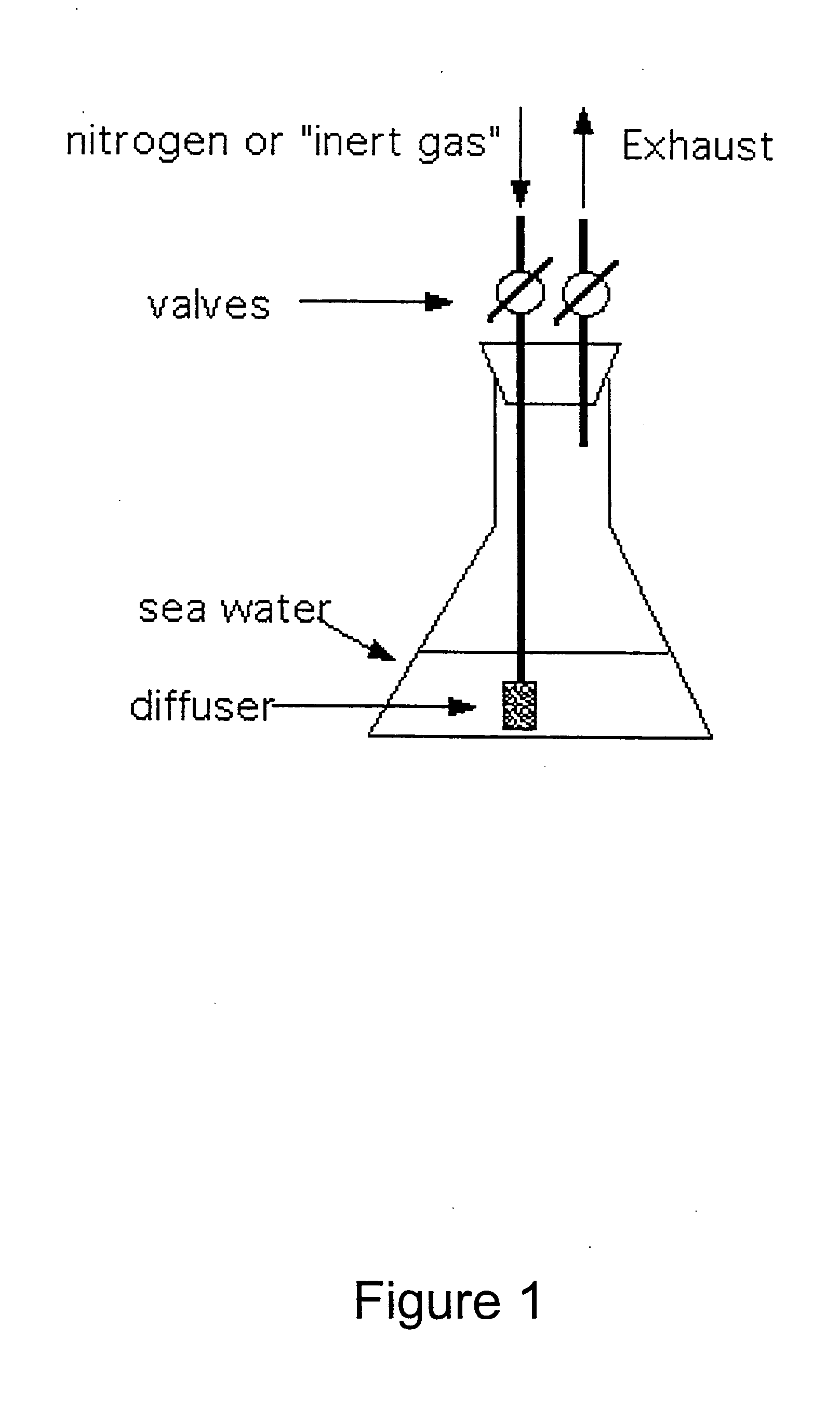

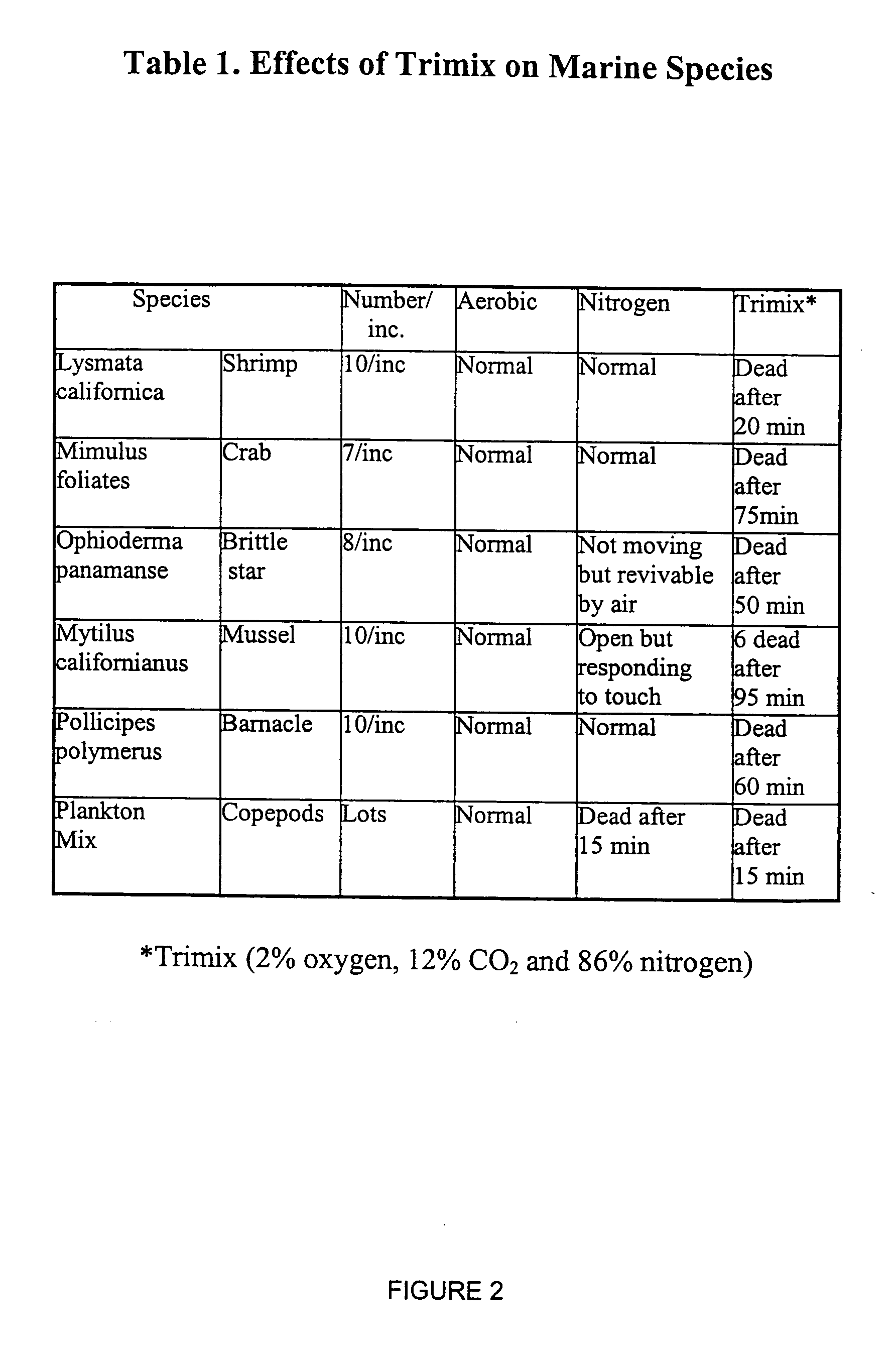

Infusion of combustion gases into ballast water preferably under less than atmospheric pressure to synergistically kill harmful Aquatic Nuisance Species by simultaneous hypercapnia, hypoxia and Acidic pH level

InactiveUS20110132849A1Effectively and efficiently altersReduced survivalAuxillariesSelf-bailing equipments/scuppersCombustionNitrogen

Owner:HUSAIN MO +3

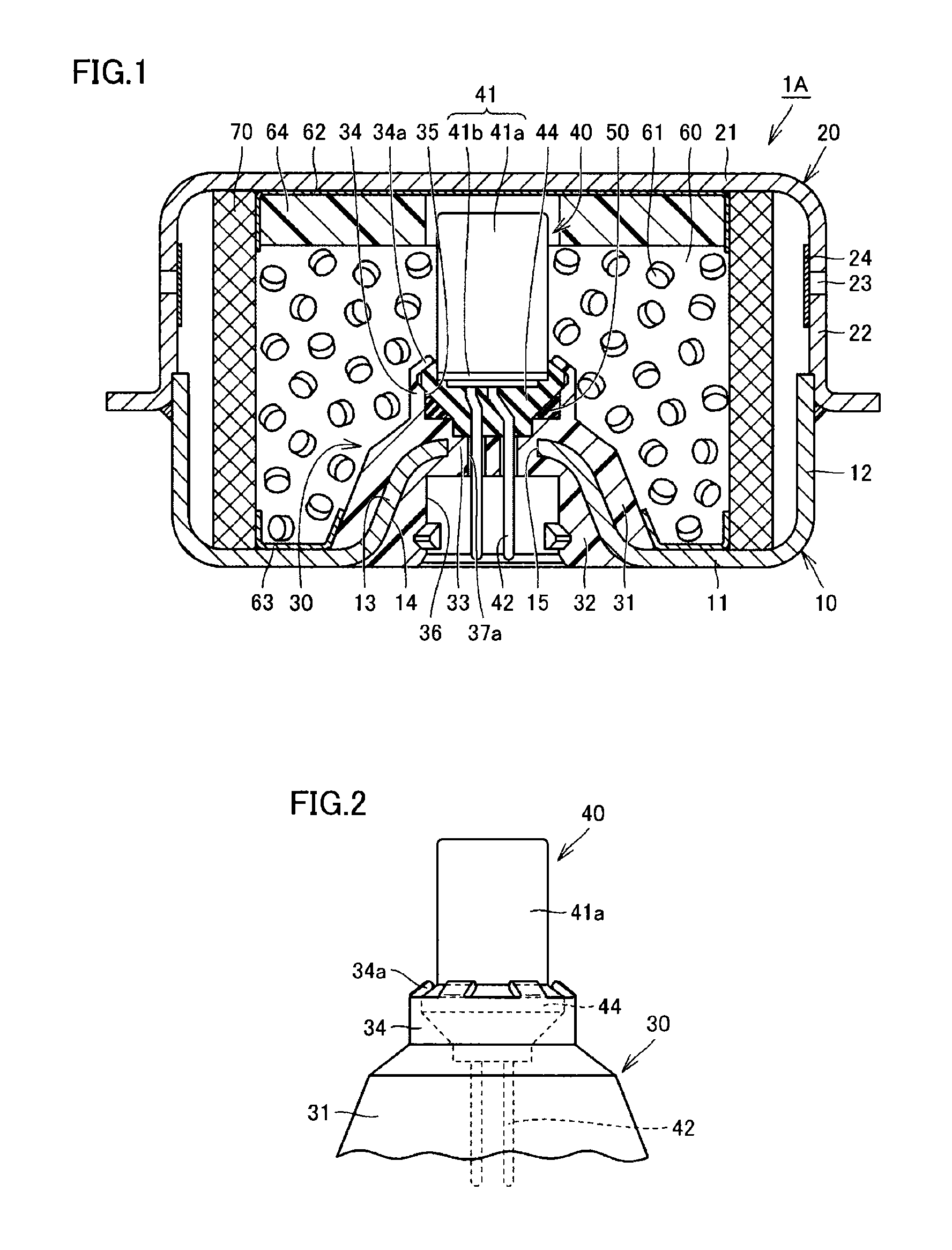

Gas generator

InactiveUS20130276664A1Low costLess restriction in assembly operationPedestrian/occupant safety arrangementPressure gas generationInert gas generatorGas generator

A gas generator includes a lower shell, an upper shell, a holding portion, an igniter, and a filter. The lower shell is made of a press-formed product formed by press-working one plate-shaped member made of metal, and includes a protruding cylindrical portion and an opening provided in the protruding cylindrical portion. The holding portion is formed from a resin-molded portion formed by attaching an insulating fluid resin material to a bottom plate portion so as to reach a part of an outer surface from a part of an inner surface of the bottom plate portion of the lower shell through the opening and solidifying the same, and includes an accommodation recess portion in a portion opposed to a top plate portion. The igniter is held by the holding portion while it is inserted in the accommodation recess portion from a side of the top plate portion and fitted therein.

Owner:NIPPON KAYAKU CO LTD +1

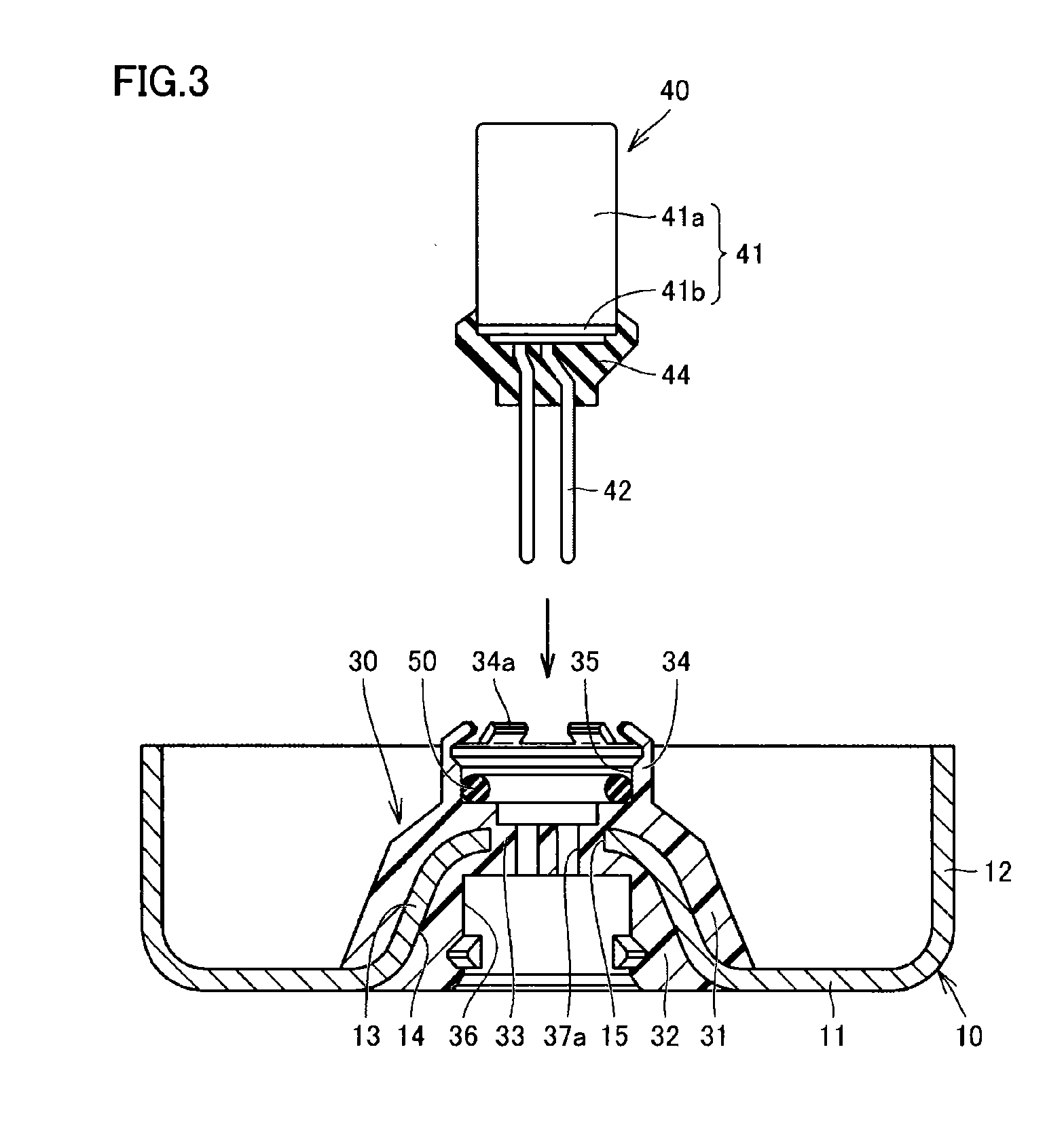

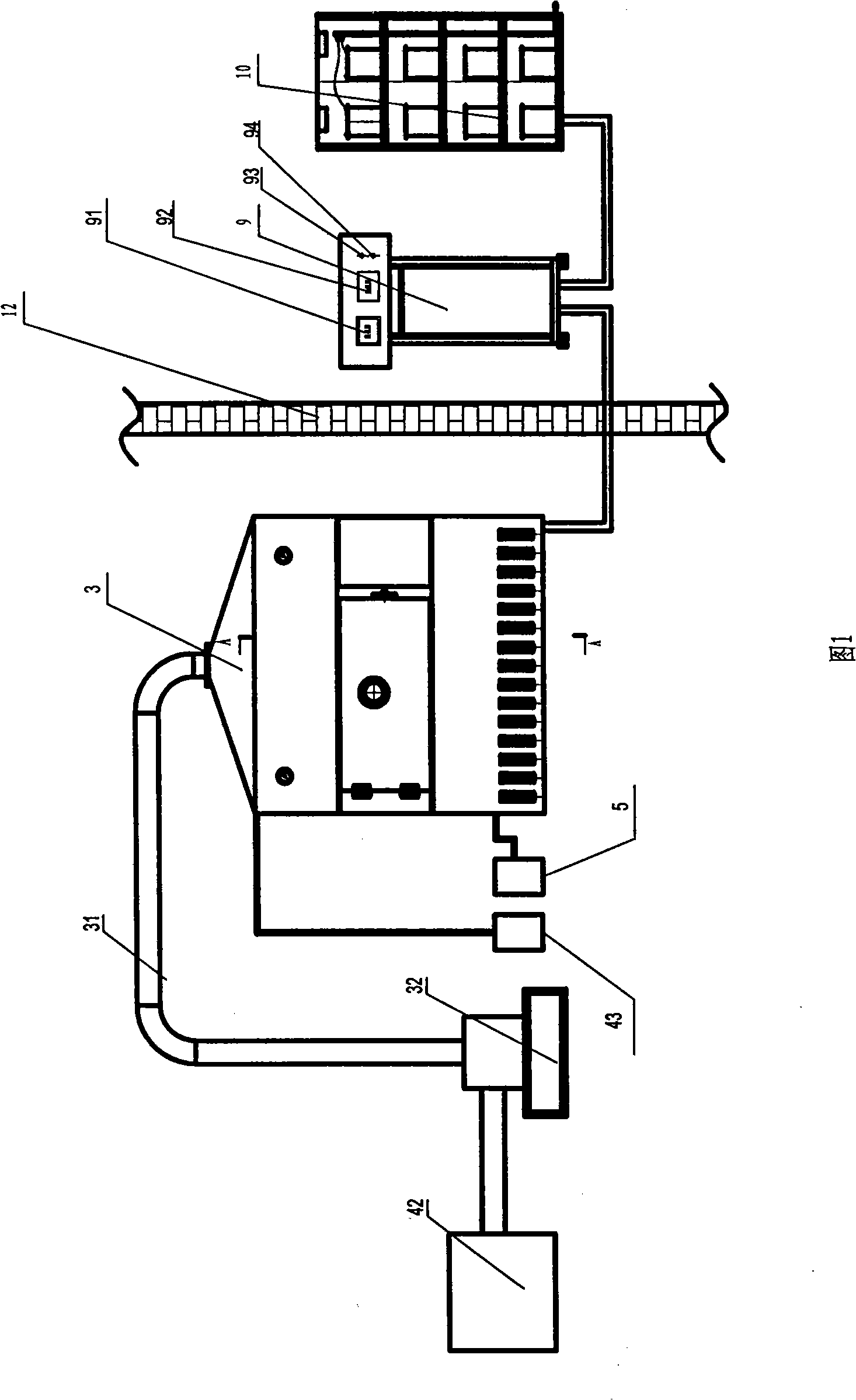

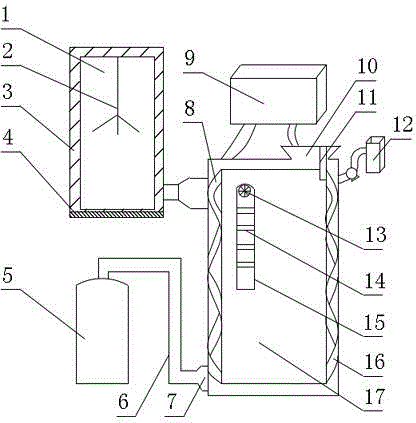

Explosion-proof box type vacuum microwave drier and operation method

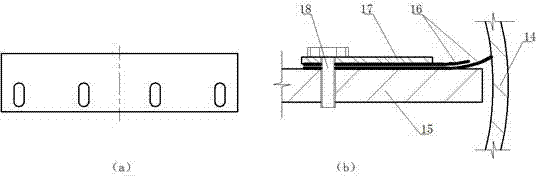

ActiveCN101358803AAvoid explosionReduce harmDrying using combination processesDrying solid materials with heatVacuum pumpingMicrowave

The present invention relates to a micro-wave drying device and an operation method, in particular relates to an anti-explosion box-typed vacuum micro-wave dryer and an operation method, and comprises a vacuum cavity body (1) and an electric appliance control cabinet (9), wherein, a micro-wave generator (6) and a material rotation device (14) are arranged inside the vacuum cavity body (1); the vacuum cavity body (1) is communicated with a vacuum pumping device (11) through a vacuum-pumping pipeline, and is characterized in that one side of the vacuum cavity body (1) is provided with an inlet (51) of the inert gas and an outlet (52) of the inert gas, and the inlet (51) of the inert gas is connected with an inert gas generator (5); an oxygen examination device (7) is arranged inside the vacuum cavity body (1). The micro-wave dryer has reasonable structure and simple design, and can prevent the explosion during the heating process of the flammable and explosive materials through a specific operation method.

Owner:广州华圆制药设备科技有限公司

Gas generator

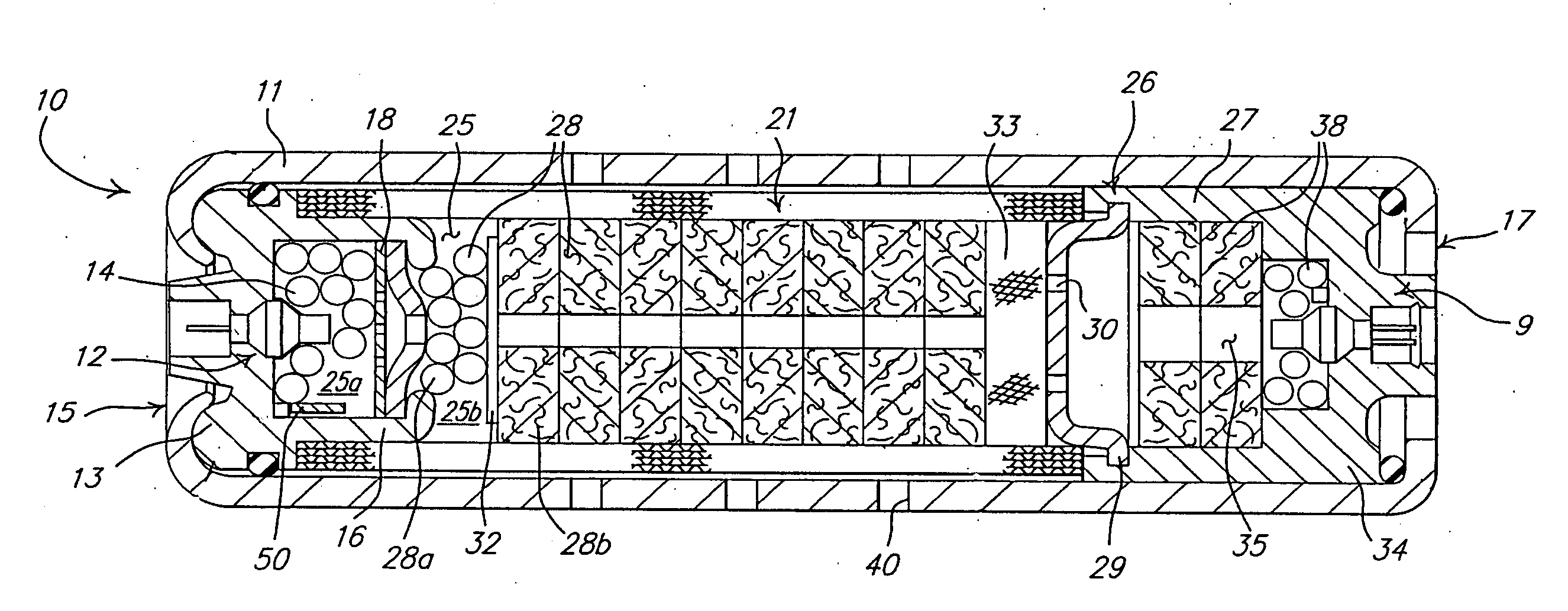

ActiveUS20090102171A1Prevent movementImprove filtering effectGaseous chemical processesPressurized chemical processProduct gasMoisture

A gas generator is provided, the gas generator having a propellant cushion that prevents movement of propellant tablets or grains by providing a bias thereagainst. Furthermore, the cushion is formed from a desiccating material thereby removing moisture and inhibiting moisture uptake by the propellant during manufacture of the gas generator. The elastomeric cushion is also able to manage the presence of chlorine-containing species during periods of inactivation of the gas generator. Accordingly, variables such as fractured propellant and / or moisture retained within the propellant are mitigated or eliminated, thereby enhancing repeatability of inflator performance.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

Polymer solution sealed deoxygenation device and method

ActiveCN104857743AImprove oxygen removal effectAccurate evaluationLiquid degasificationEngineeringPolymer solution

The invention discloses a polymer solution sealed deoxygenation device and a method. The polymer solution sealed deoxygenation device comprises a sealed container used for accommodating a polymer solution, wherein the upper part of the sealed container comprises at least two connecting ports including a first connection port and a second connecting port, the lower part is provided with a liquid outlet, and the first connection port is connected with an insert gas generator; a vacuumizing mechanism which is connected with the second connection port, and is used for vacuumizing and deoxidizing of the sealed container and the polymer solution in the sealed container; an oxygen measuring mechanism which is connected with the liquid outlet, and is used for detecting oxygen content of the polymer solution in the sealed container. The polymer solution sealed deoxygenation device can be used for removing oxygen in the polymer solution preferably, measuring oxygen content of the polymer solution accurately, and realizing accurate, convenient, and high efficiency evaluation on the long-term stability of the polymer solution.

Owner:CHINA PETROLEUM & CHEM CORP +1

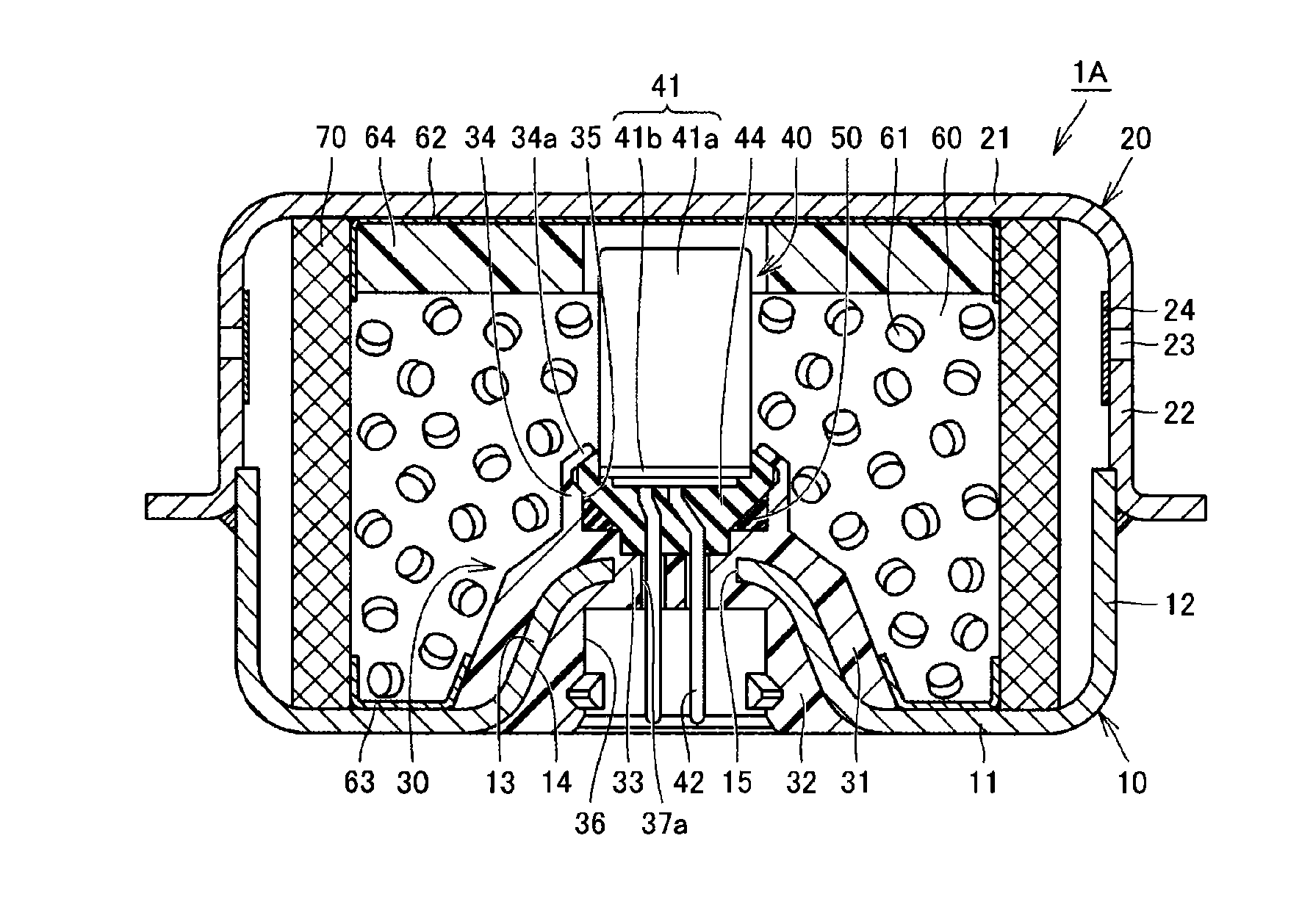

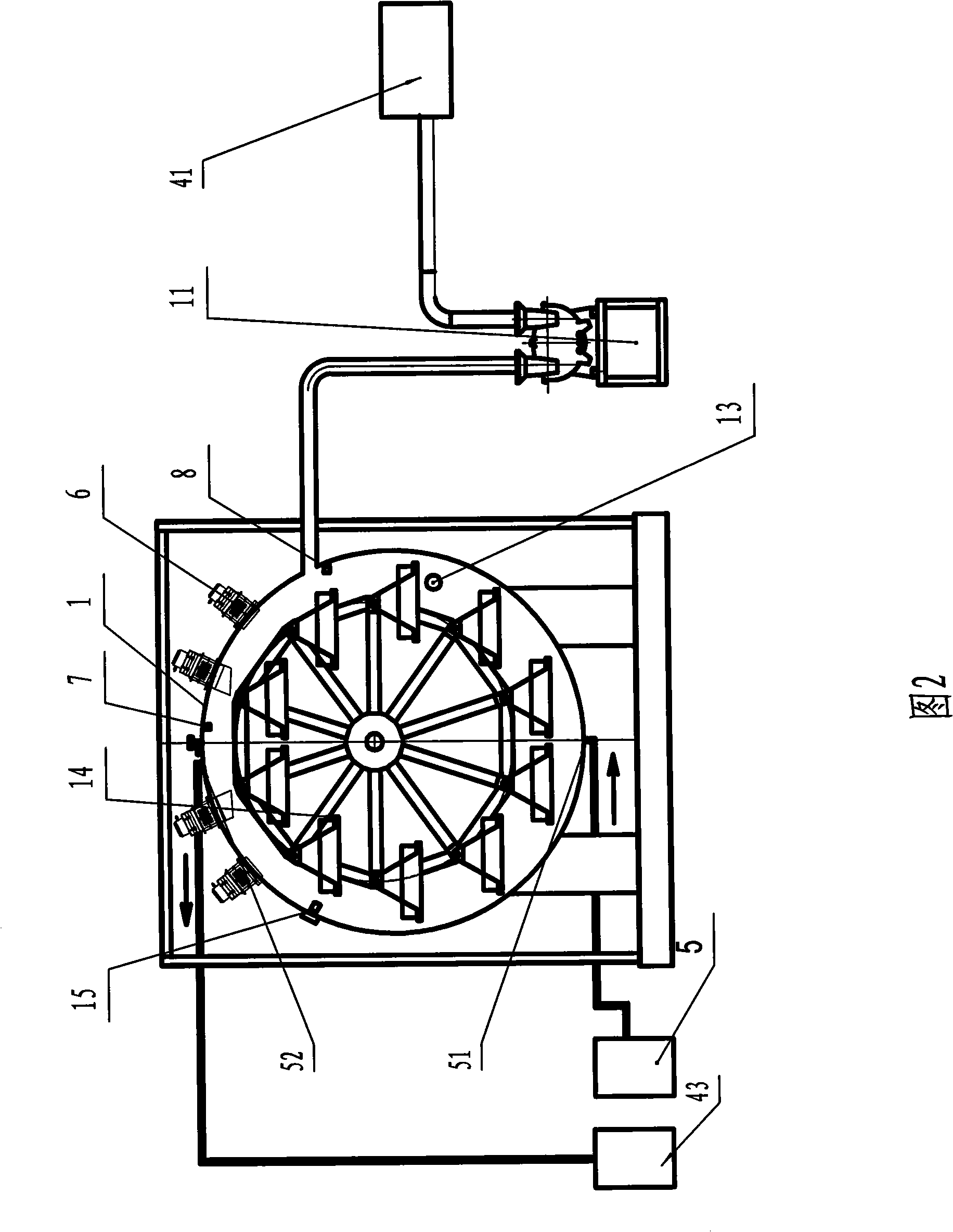

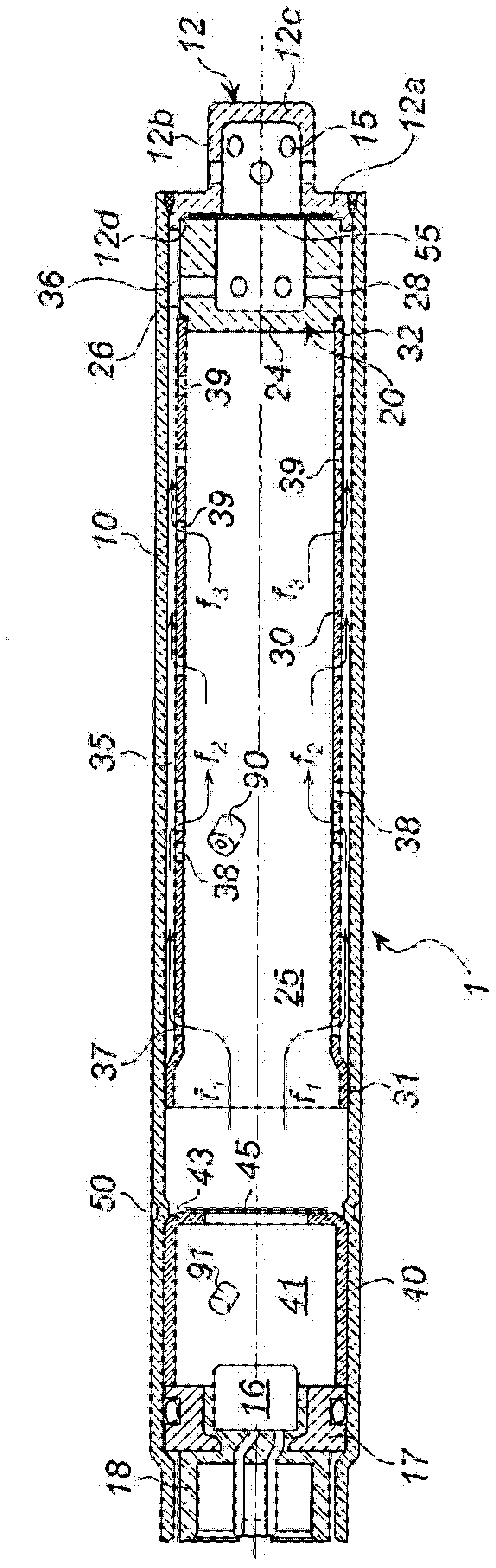

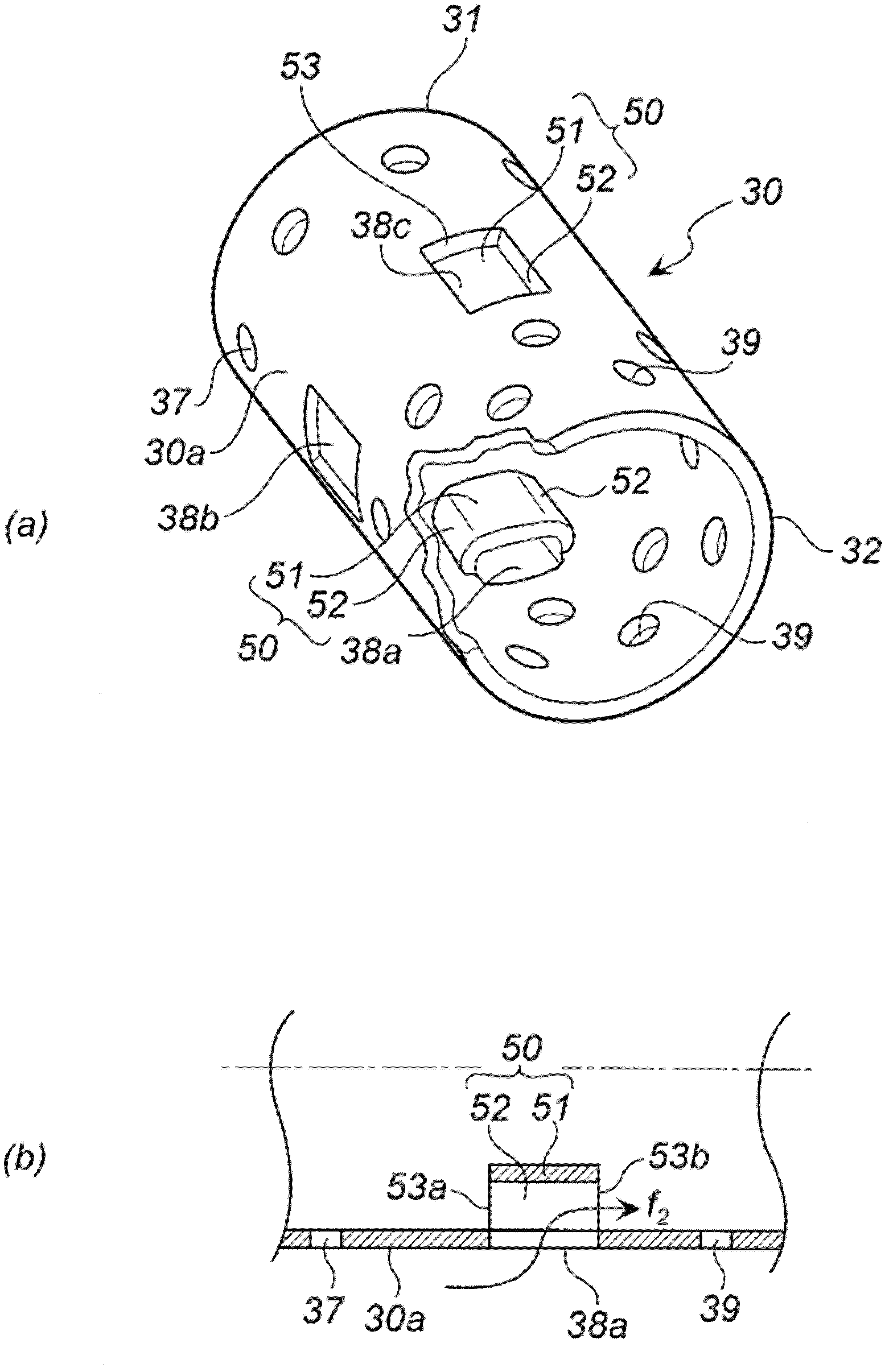

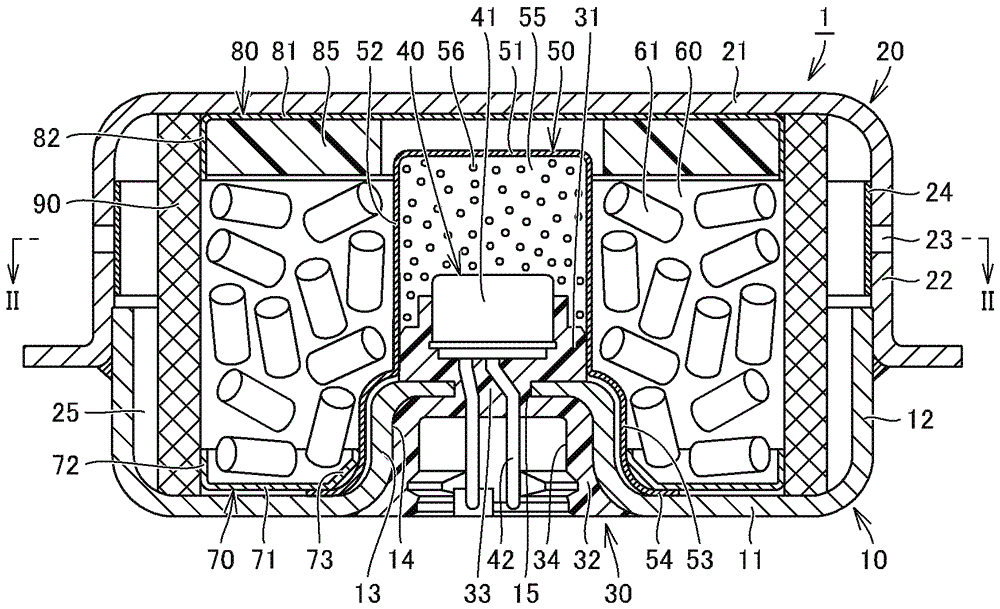

Gas generator

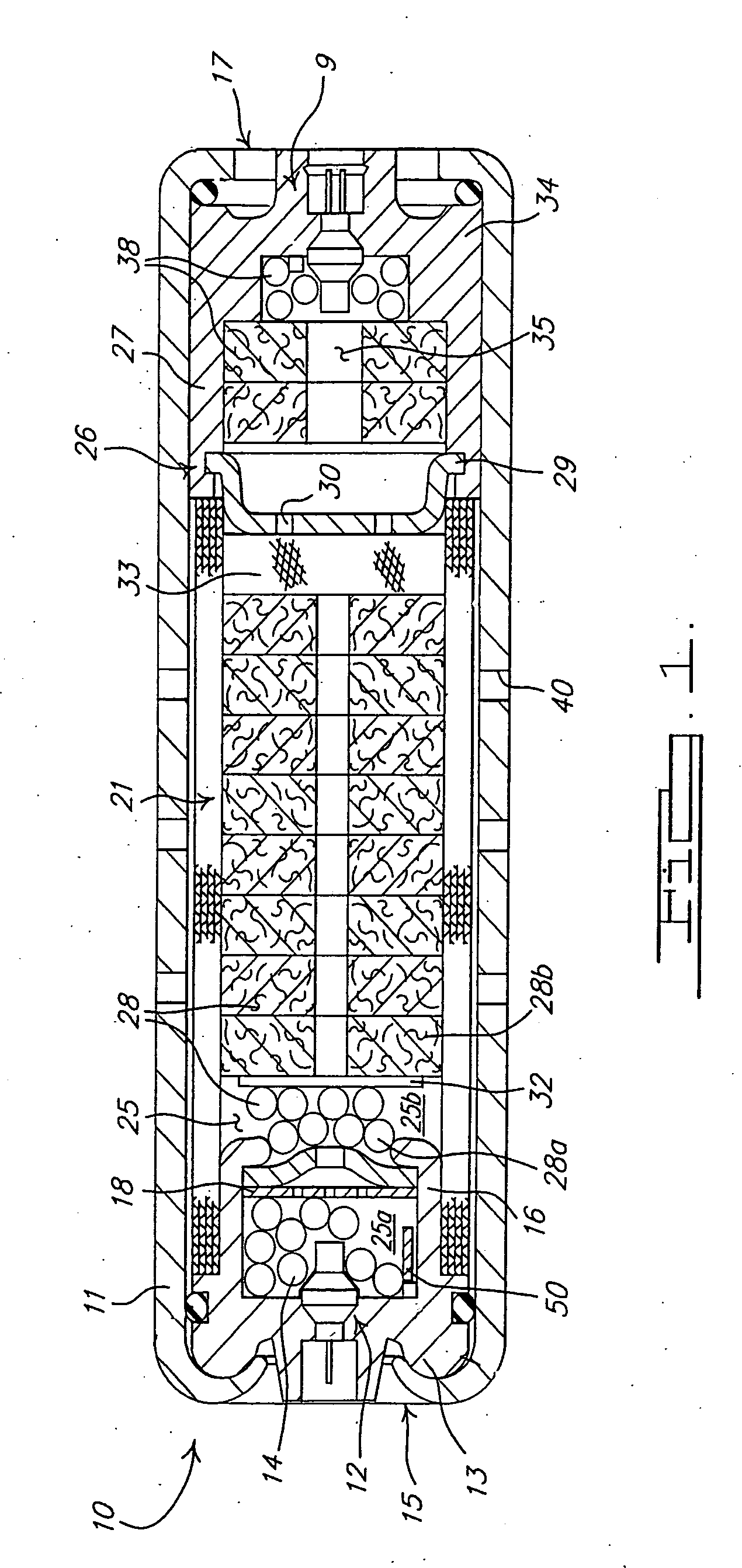

ActiveCN102421642APedestrian/occupant safety arrangementGas generation devicesCombustion chamberSignal generator

Gas generator including: a tubular housing (10), an ignition device (16) attached at one end and a diffuser (12) having a gas discharge port (20), attached at the other end, a tubular member (30), being disposed inside the tubular housing (10) and a tubular gap (36) leading to the gas discharge port is formed, a combustion chamber (25) provided inside the tubular member (30) for accommodating a gas generating agent, a first gas passage hole and a second gas passage hole formed on the first end side and the second end side, respectively, and an opening portion formed between the first gas passage hole and the second gas passage hole, such that they are communicating the combustion chamber (25) with the tubular gap (36), a projecting portion (50) provided in the opening portion such that the projecting portion projects into at least one of the combustion chamber (25) and the tubular gap (36).

Owner:DAICEL CHEM IND LTD

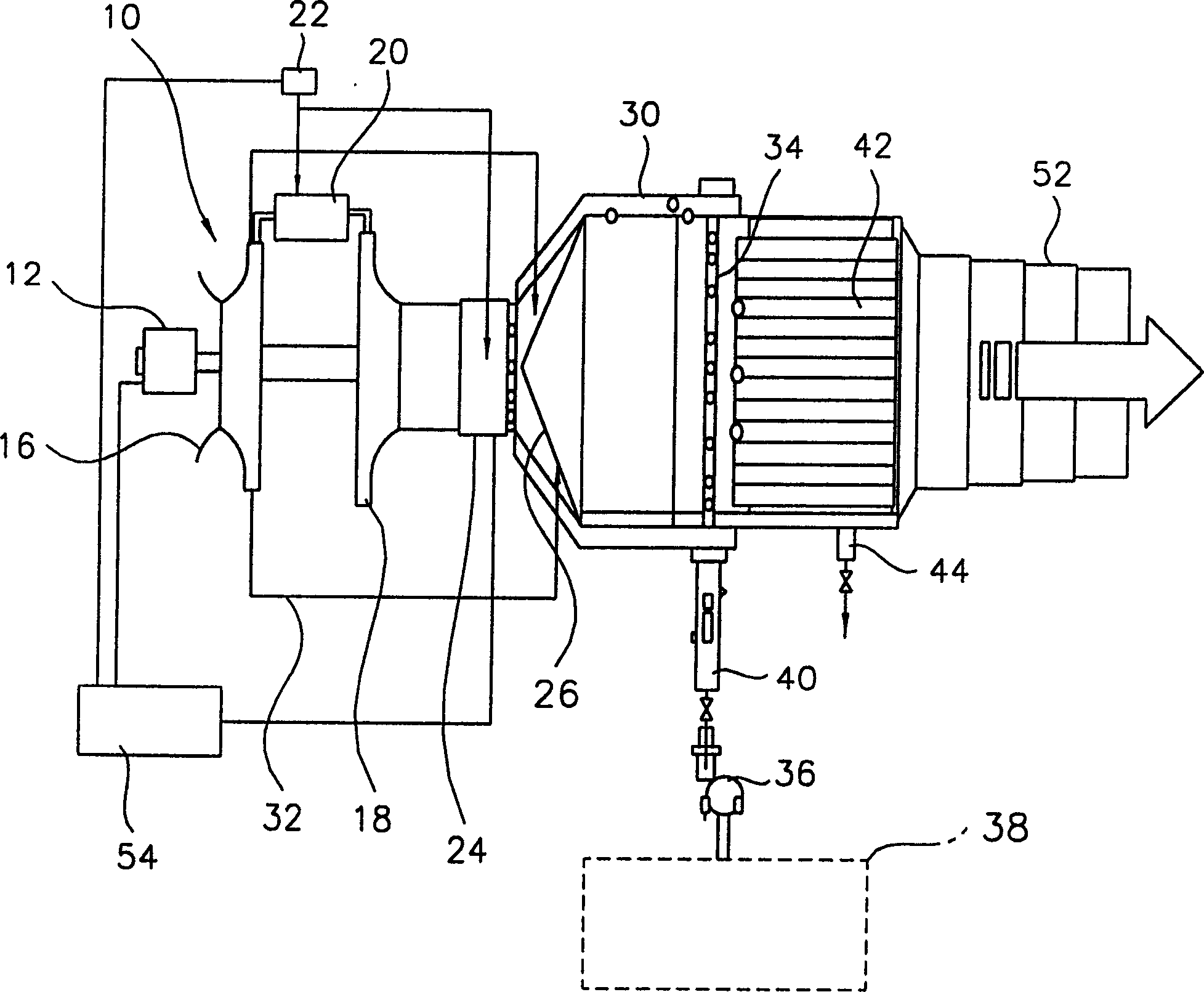

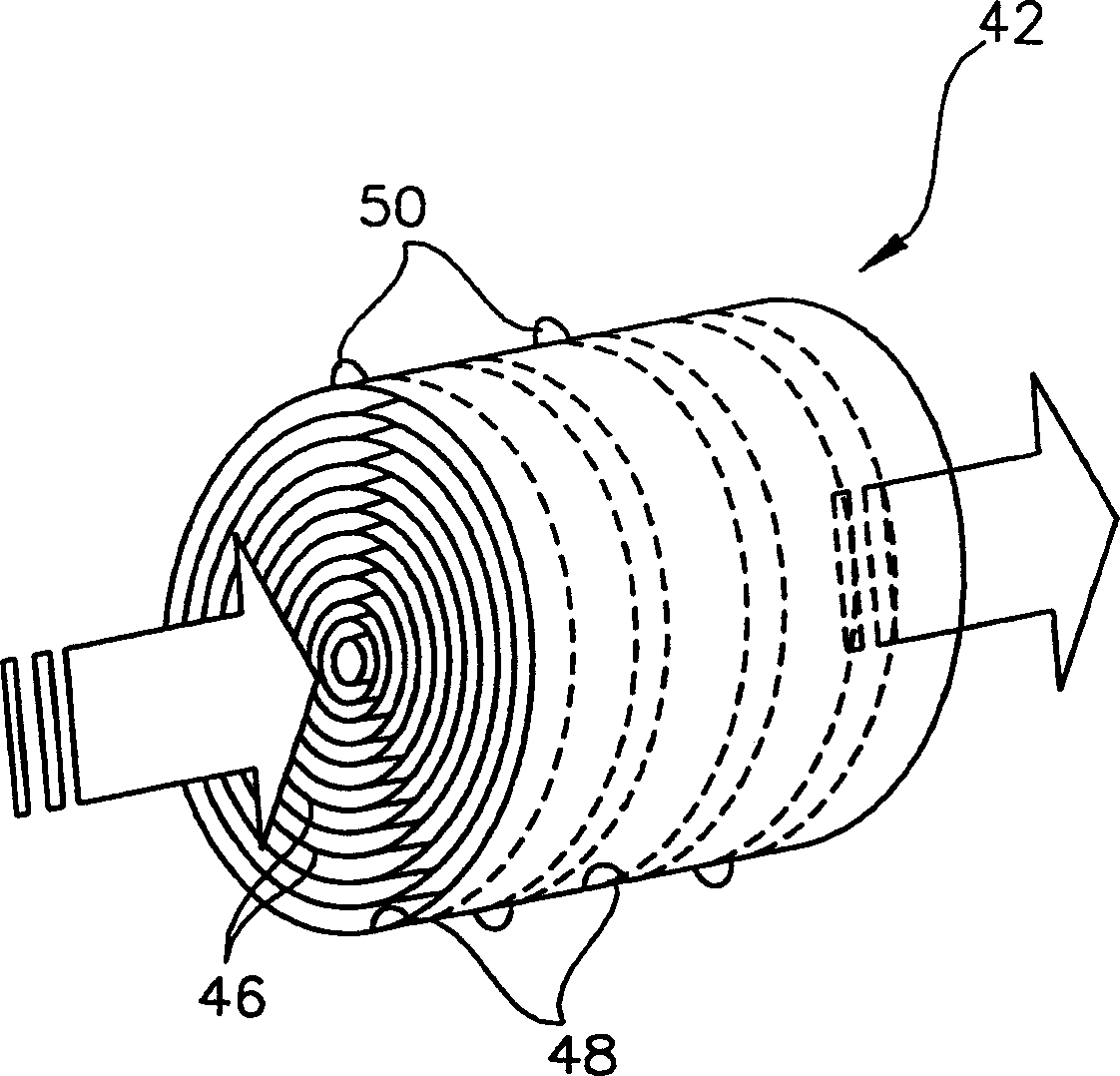

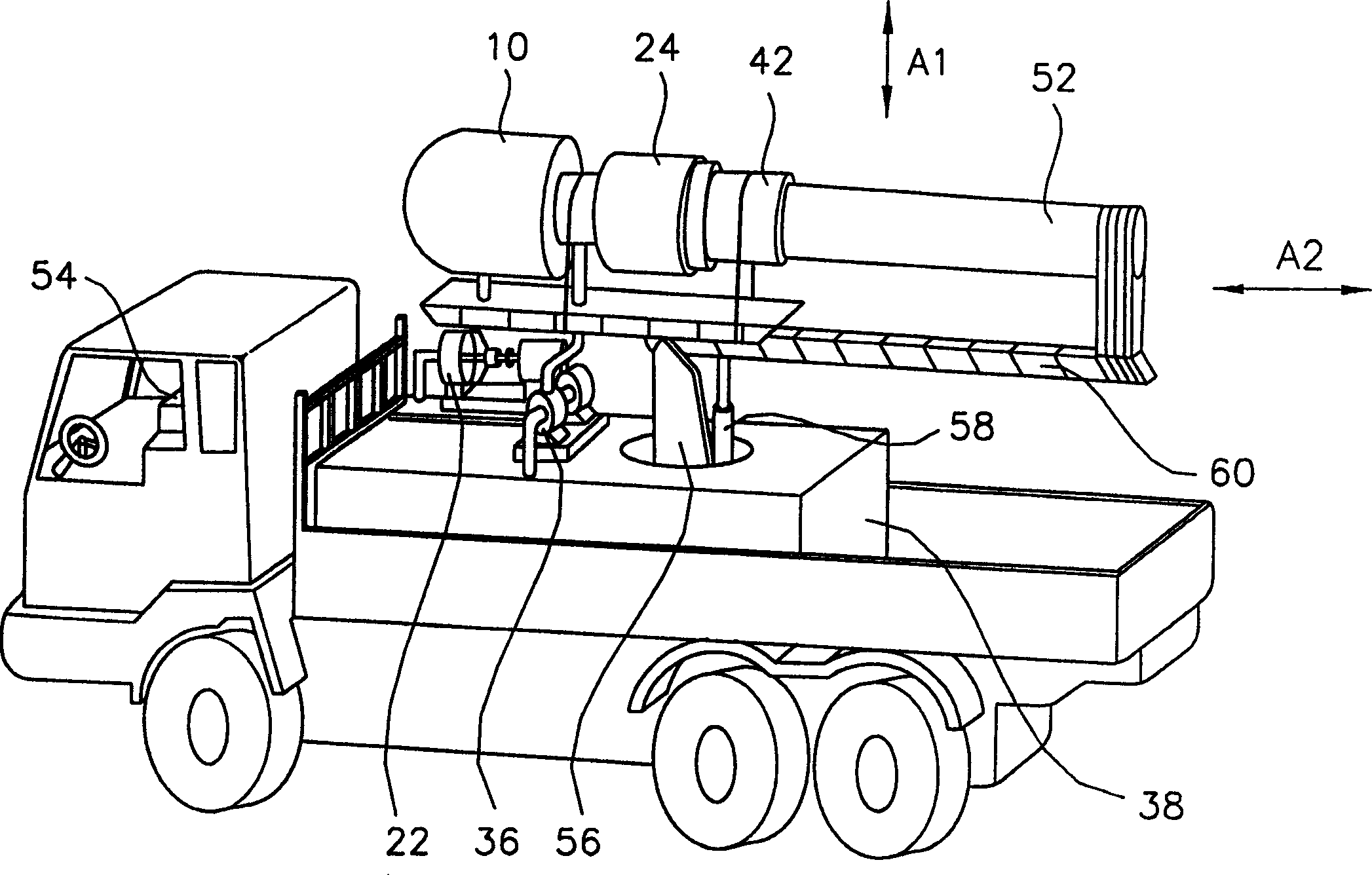

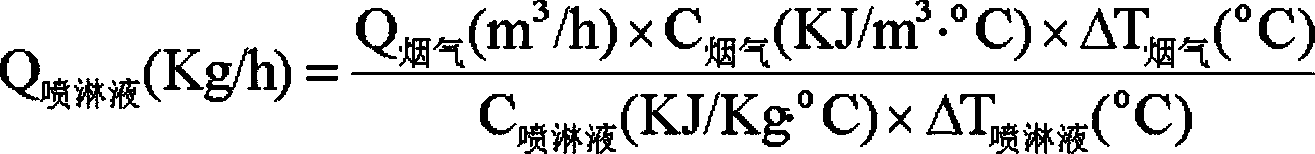

Inert gas generator fire suppressing

Disclosed is an inert gas generator to produce a large quantity of inert gas within a short period of time .The inert gas generator comprises: a gas turbine consisting of a starter motor, compressor, combustor and turbine; and afterburner being connected to the exit of the gas turbine to re-burn the gas of once burned in the primary combustor and being equipped with a flame stabilizer; a cooling chamber being equipped with spray nozzles to eject water to decrease the gas temperature in the afterburner exit; an evaporator set to further cool the gas-steam mixture from the afterburner; a cooling chamber and spray nozzles; an exhaust nozzle to guide the direction of the inert gas-steam mixture of low temperature and oxygen content; and a controller for controlling the starter motor, the fuel pump and combustor. The inert gas generator mounted on a movable vehicle can promptly suppress the fire occurred in various places with least amount cost possible.

Owner:KOREA INST OF MASCH & MATERIALS +1

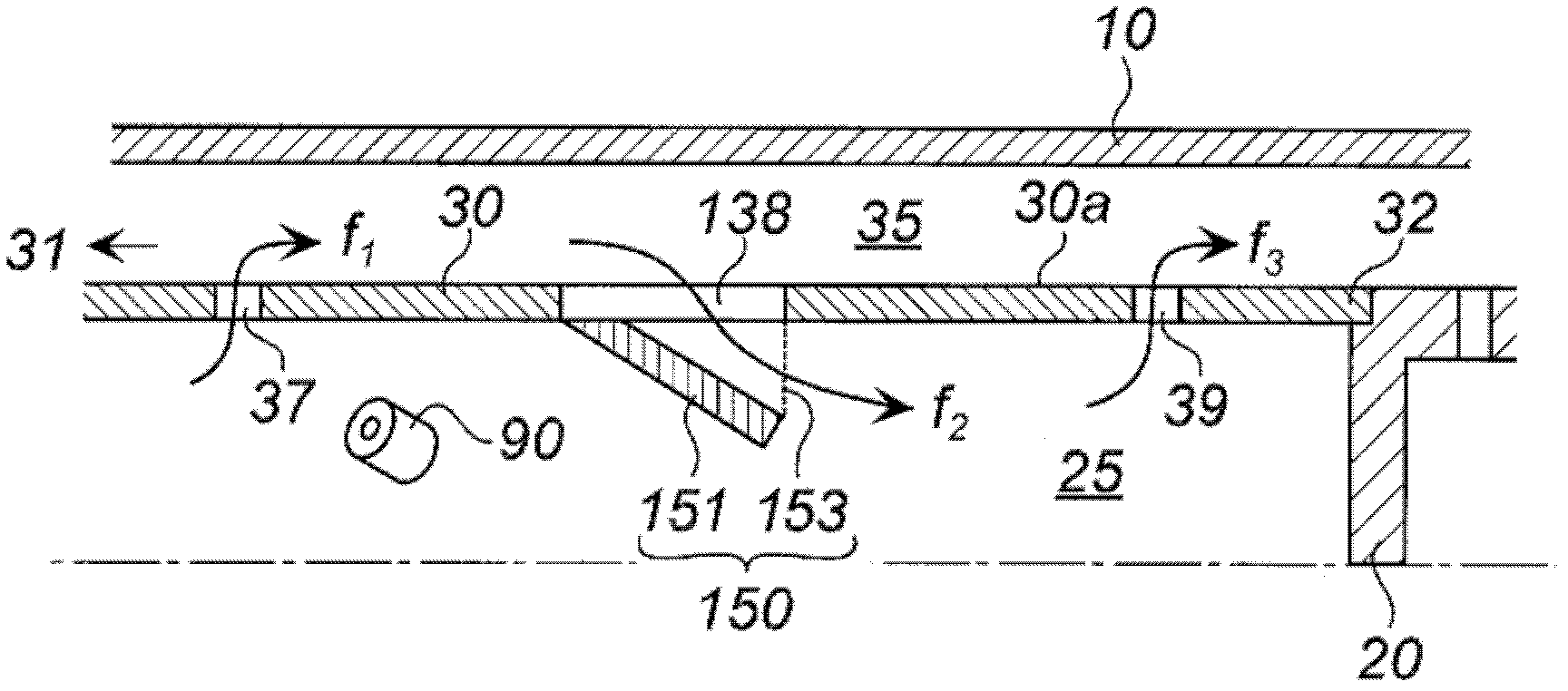

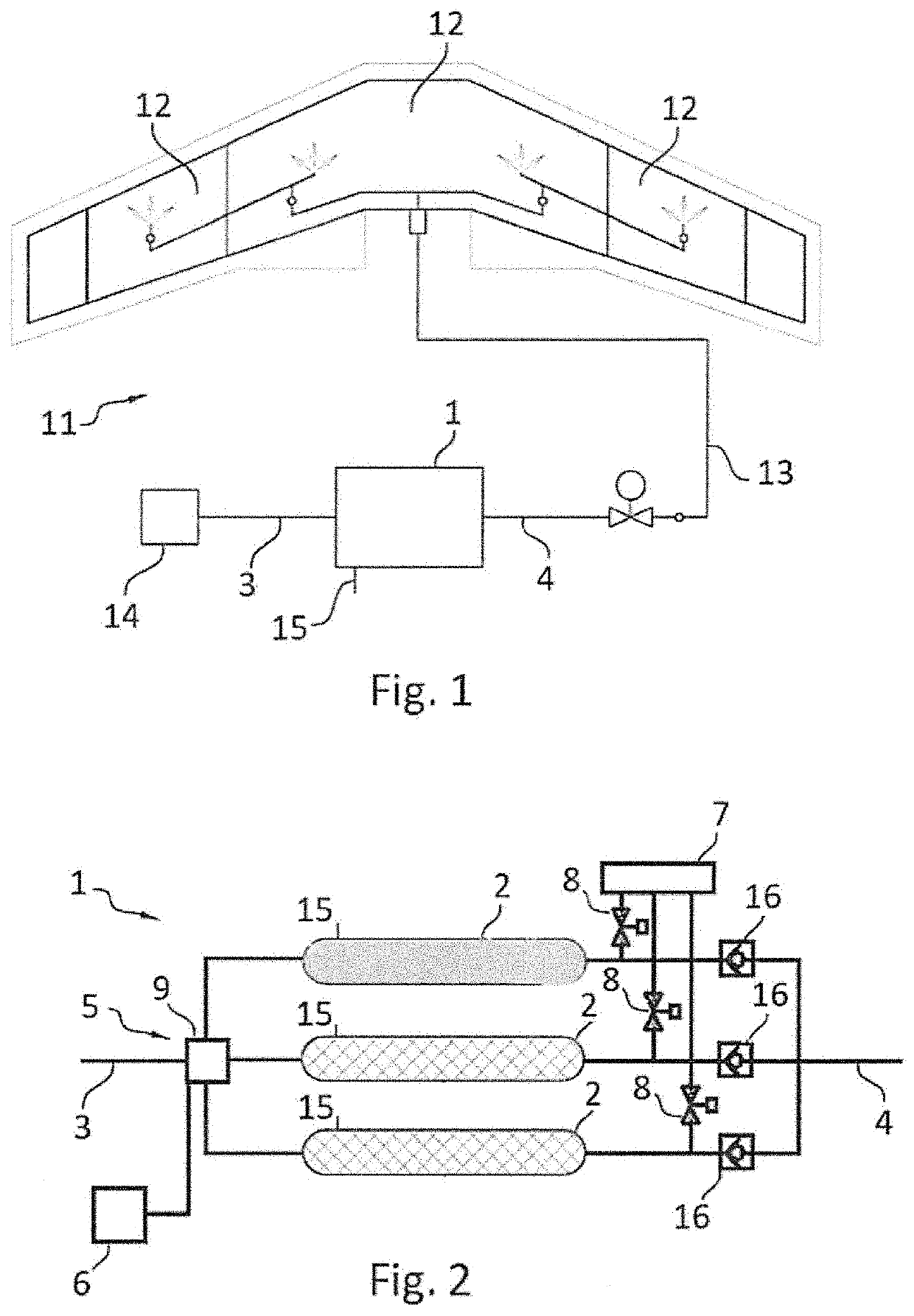

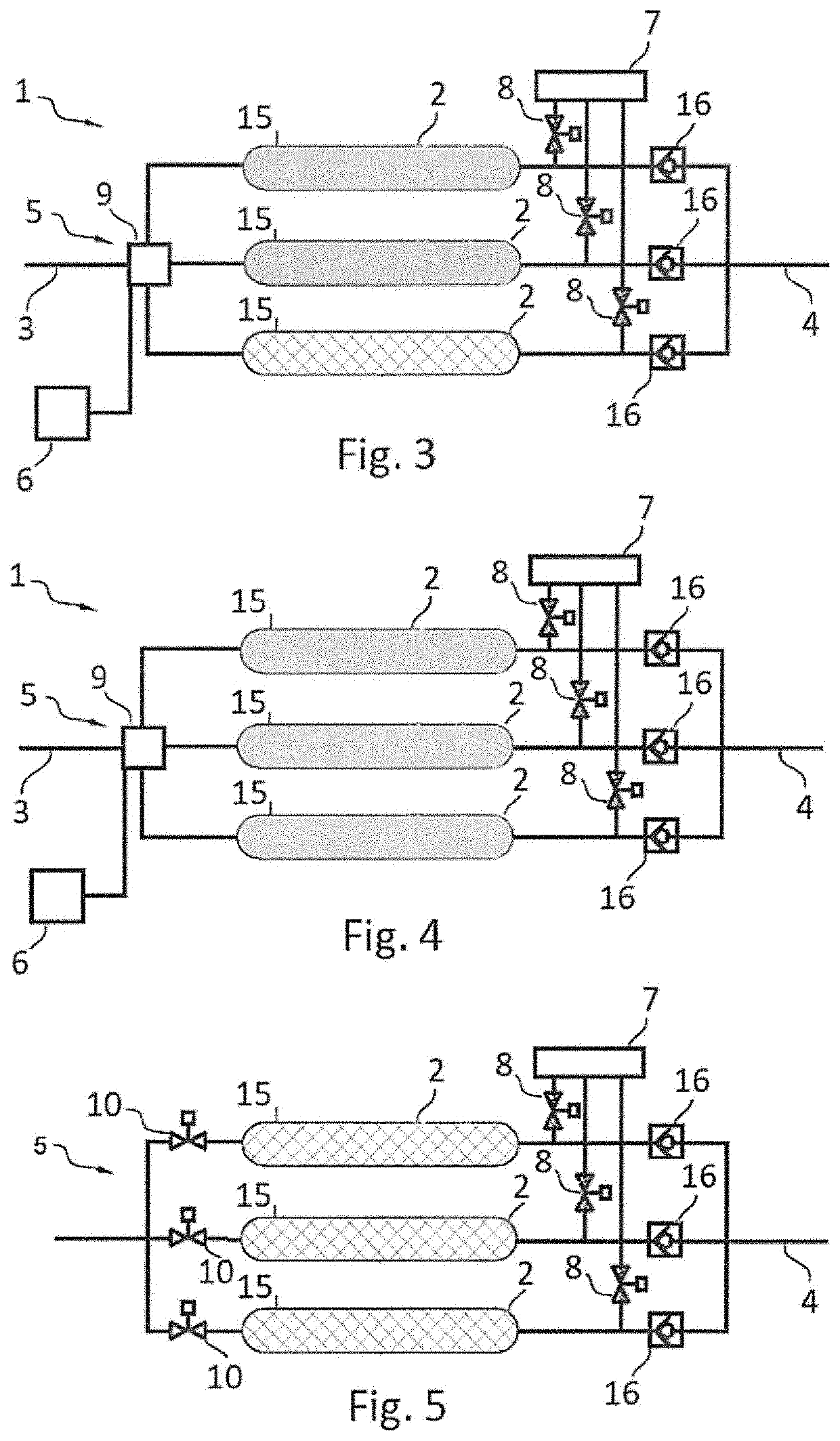

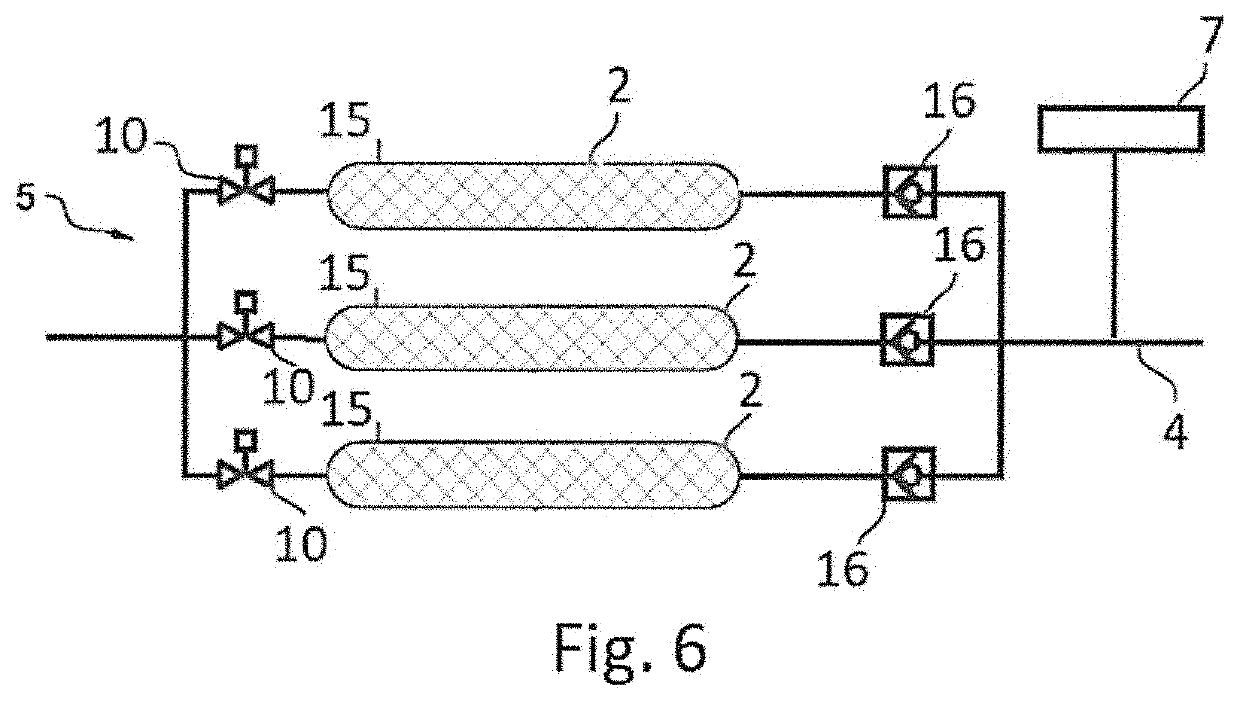

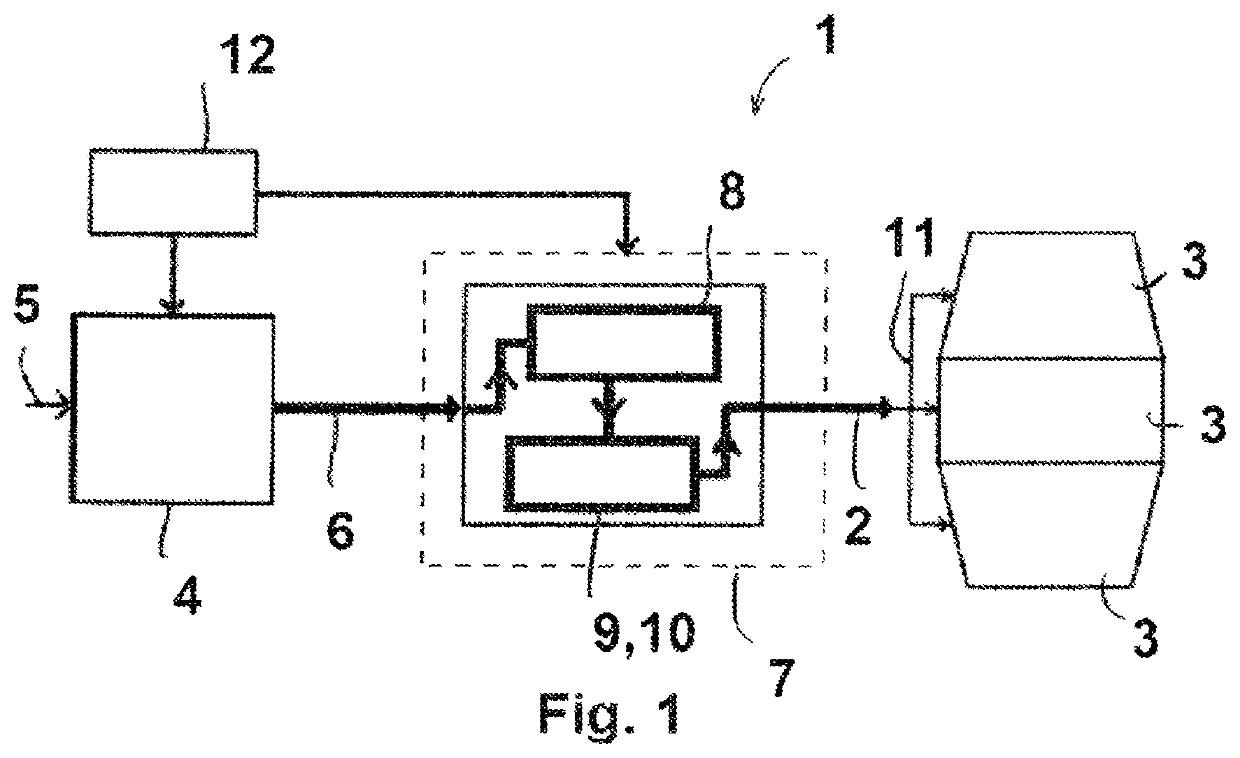

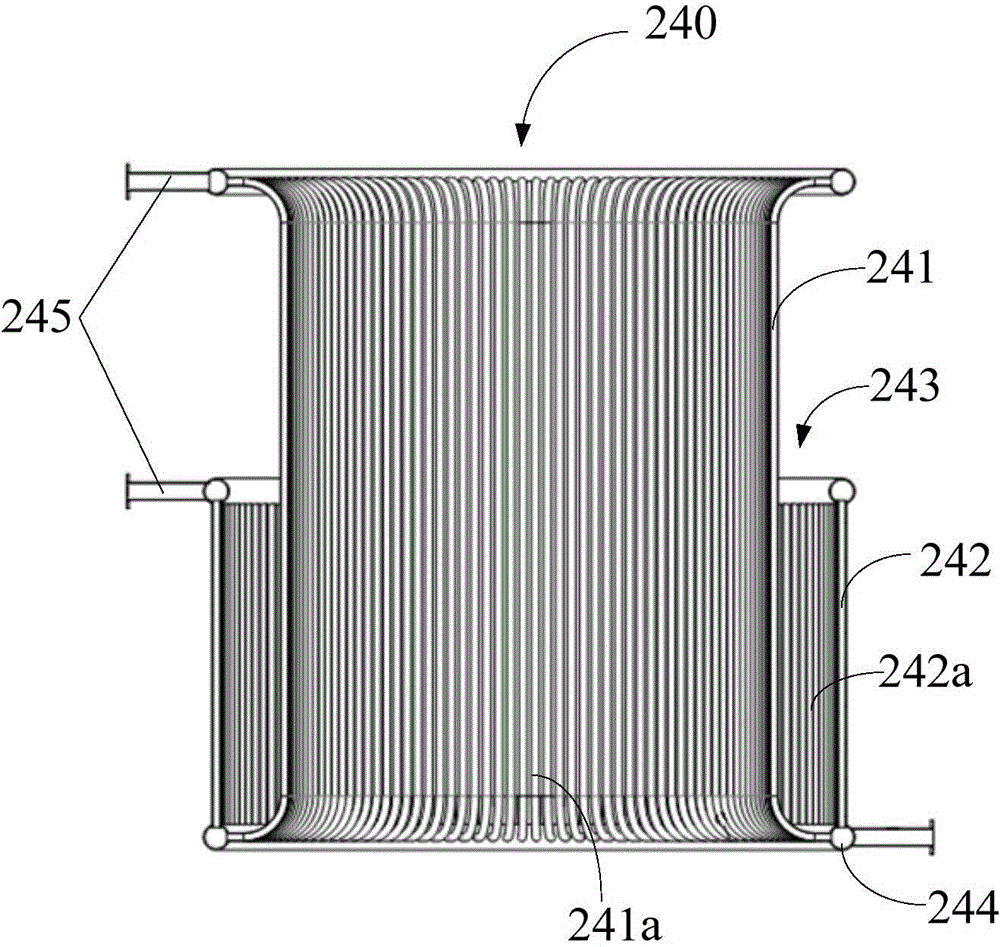

Inert gas generator for an inerting system of an aircraft system of an aircraft fuel tank, and inerting method

ActiveUS20200164307A1Small sizeEasy to useGas treatmentAircraft health monitoring devicesThermodynamicsInerting system

A generator of inert gas from an airflow, in an inerting system for at least one aircraft fuel tank is disclosed. The generator includes a system with an air inlet and means for distributing the airflow to a plurality of air separation modules arranged in parallel on the air system to deplete oxygen in the air and generate a nitrogen-enriched inert gas at the outlet. The generator also includes a programed control unit for the distribution means to selectively supply air to a single, a portion or all of the air separation modules, depending on the flight phase of the aircraft.

Owner:SAFRAN AEROTECHNICS SAS

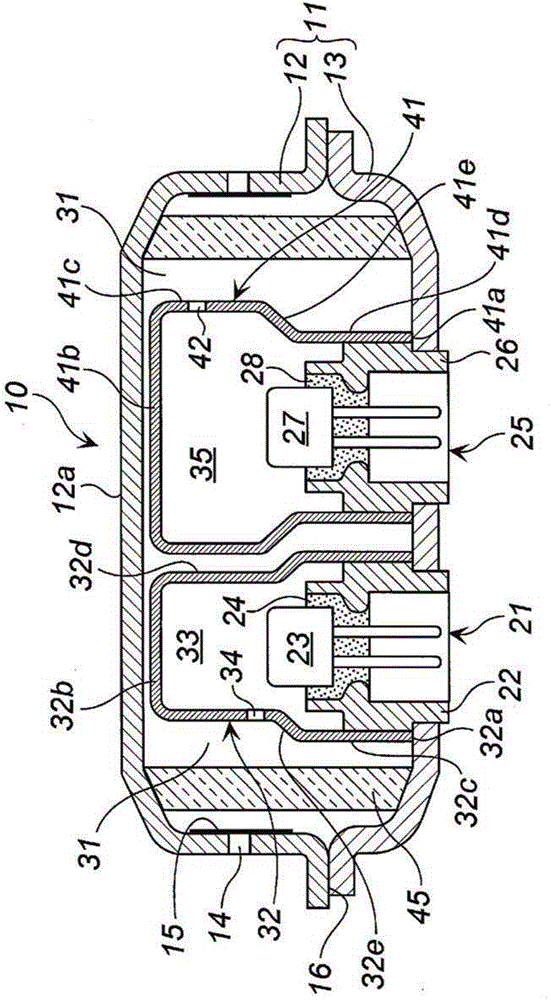

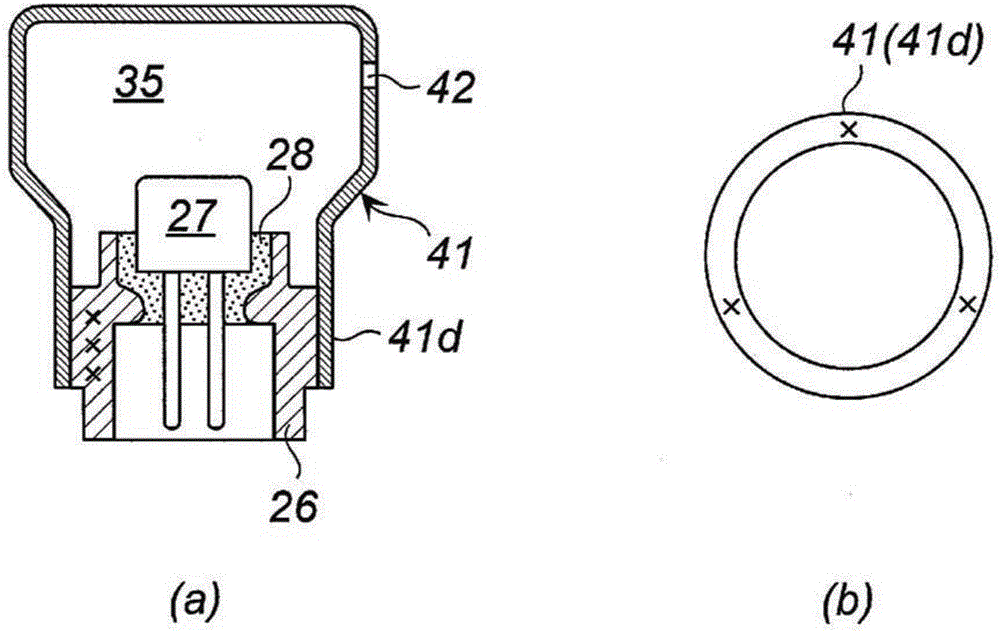

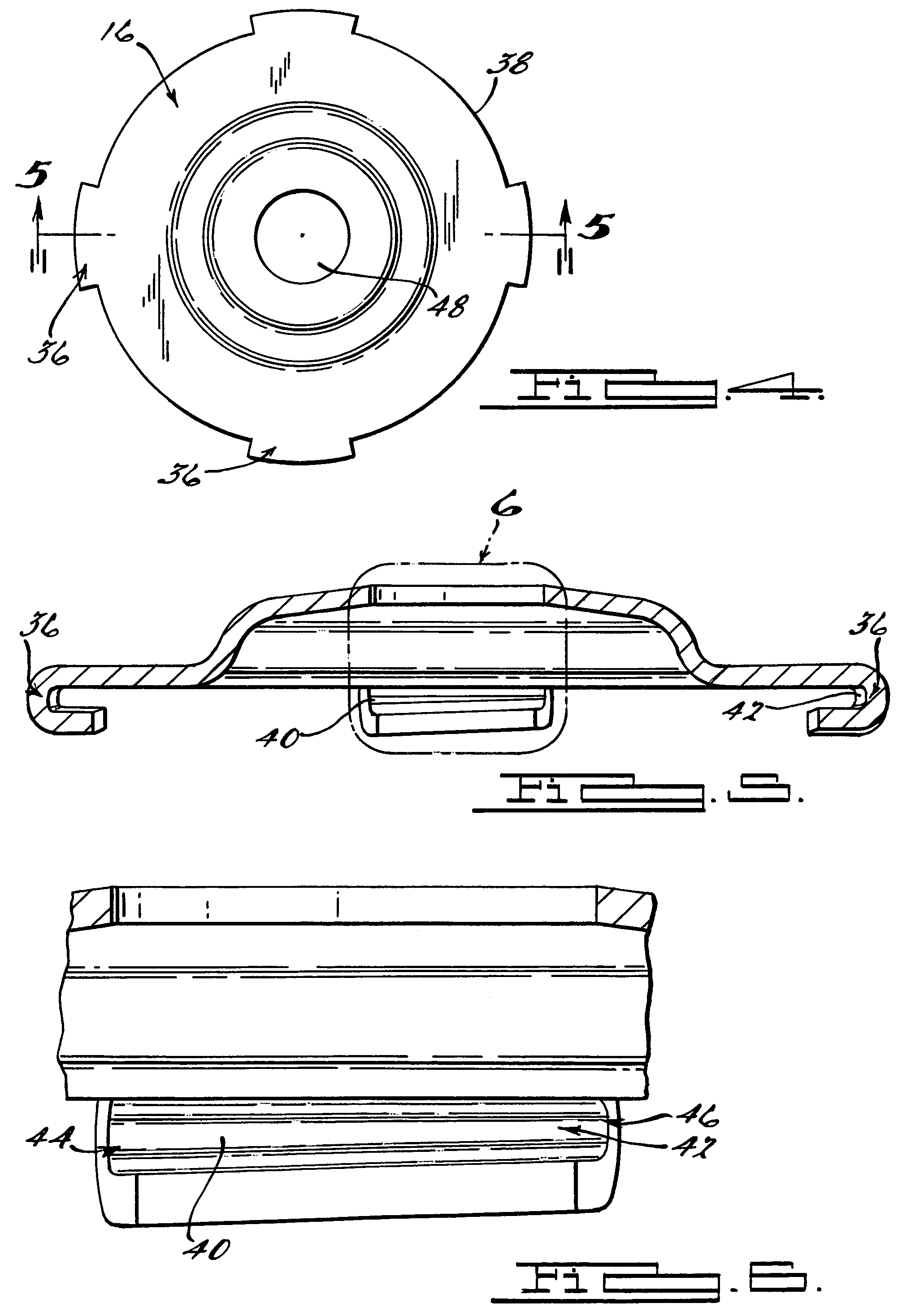

Gas generator

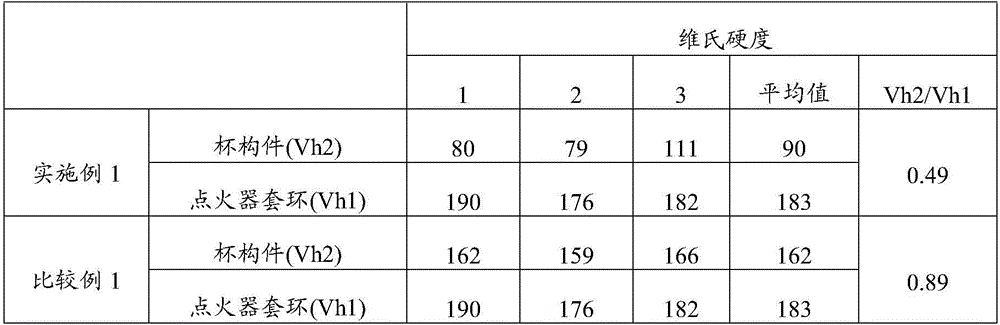

ActiveCN105873800APedestrian/occupant safety arrangementGas generation devicesHardnessSignal generator

The purpose of the present invention is to provide a gas generator that has a combination of an igniter collar for an igniter and a cup member as components such that the adhesion strength when the cup member is press-fitted to the igniter collar of the igniter can be made higher. This gas generator (10) has, inside a housing (11), igniters (23, 27) formed from igniter bodies surrounded by igniter collars (22, 26) and ignition means chambers (33, 35) which store an ignition charge, said gas generator (10) being characterized in that the ignition means chambers (33, 35) are formed by means of press-fitting such that opening-side inner circumferential wall surfaces of the ignition means chamber cups (32, 41) storing the ignition charge are brought into close contact with the outer circumferential wall surfaces of the igniter collars (22, 26) of the igniters (23, 27), and the ratio (Vh2 / Vh1) of the average Vickers hardness (Vh2) of the ignition means chamber cups (32, 41) to the average Vickers hardness (Vh1) of the igniter collars (22, 26) is in the range of 0.25-0.65.

Owner:DAICEL CORP

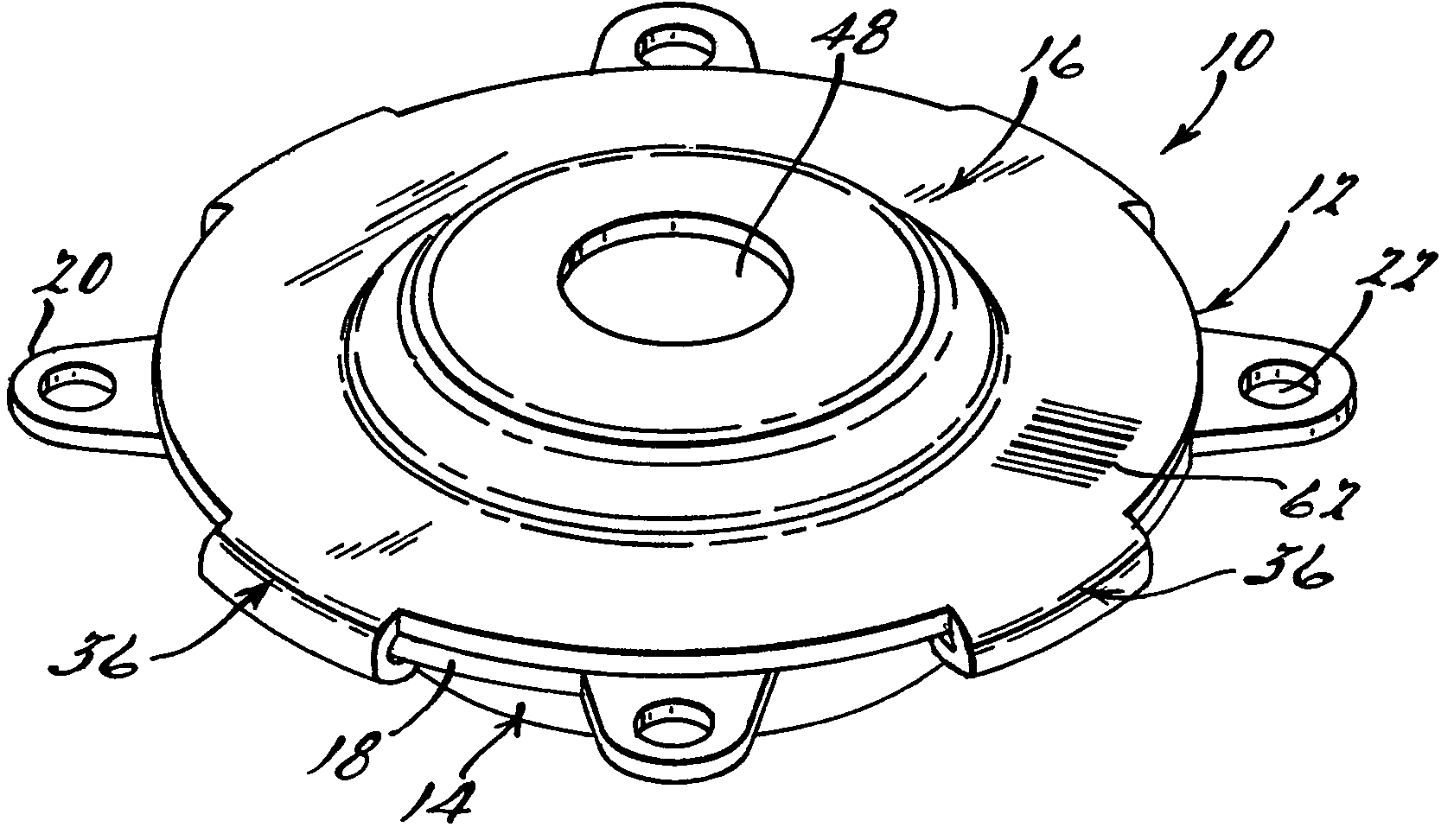

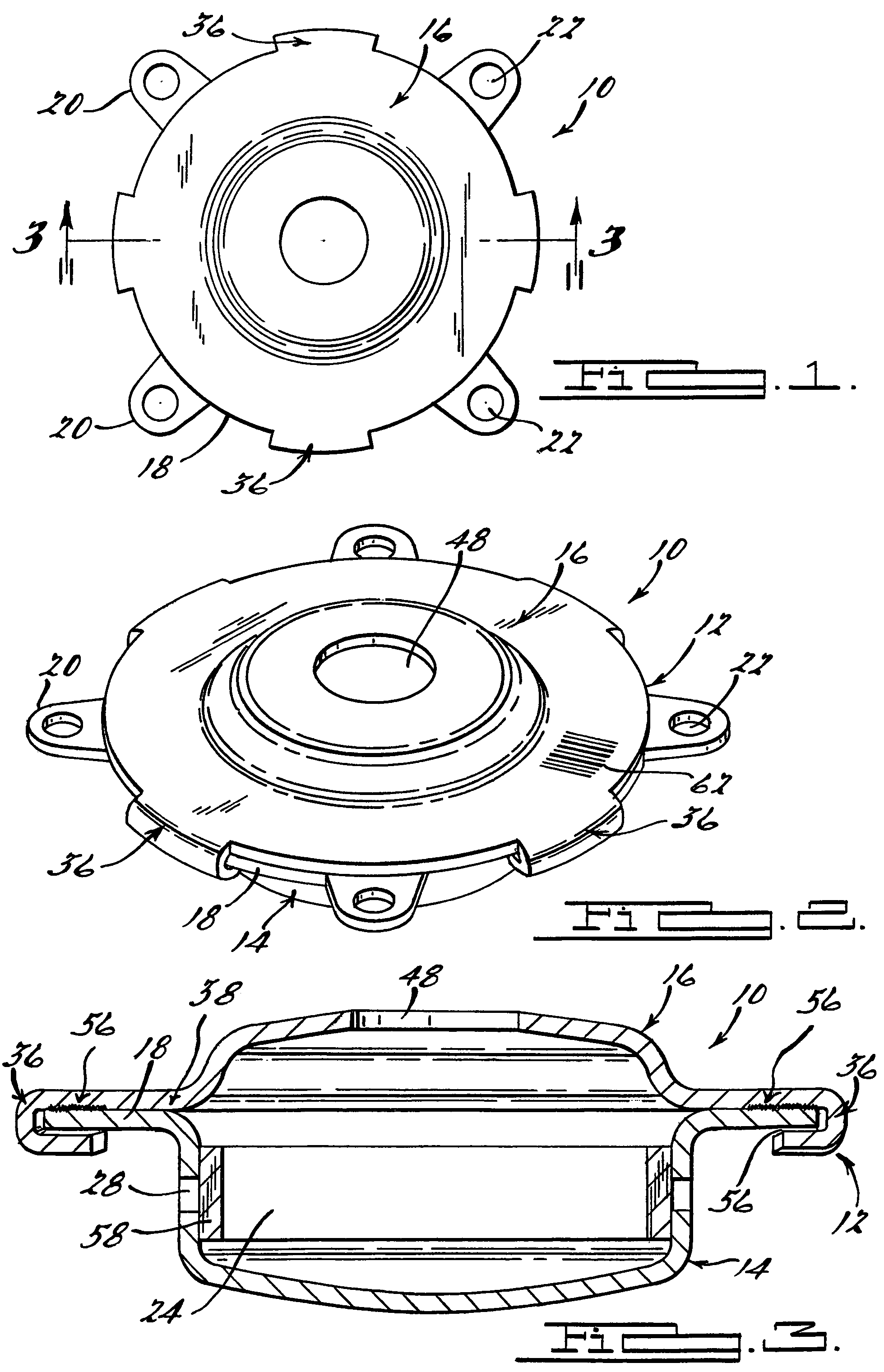

Gas generator

The present invention provides a gas generator (10) that includes a housing (12) formed from coupling a cap (14) and a base (16) in nested relationship. At least one attachment member (20) is preferably formed symmetrically about and integral to a peripheral flange (18) of the cap (14). The contour of a peripheral edge (60) formed from recessed and protruding portions provides interlocking communication between the cap (14) and the base (16). A plurality of hook members (36) is symmetrically formed about the peripheral edge (38) of the base (16). Each hook member (36) corresponds to a respective protruding portion (30) of the cap (14). An arcuate groove (40) is formed by an inner wall (42) of each respective hook member (36). The groove (40) is preferably tapered whereby the arcuate length of the groove or the inner wall (42) is greater at the first end (44) than at the second end (46). As a result, the base (16) when rotatably fixed to the cap (14) provides an interference fit at the hook / cap periphery interface.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

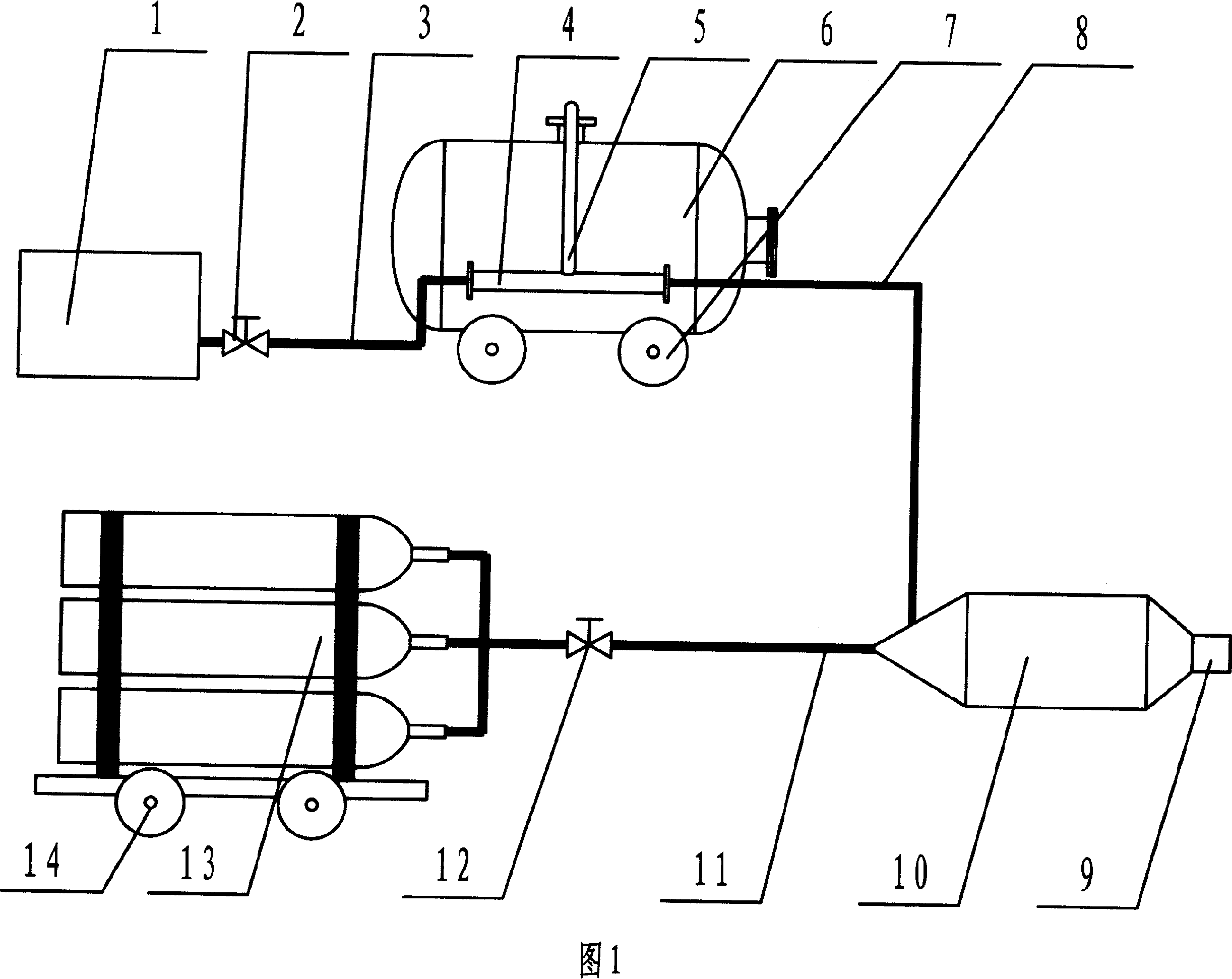

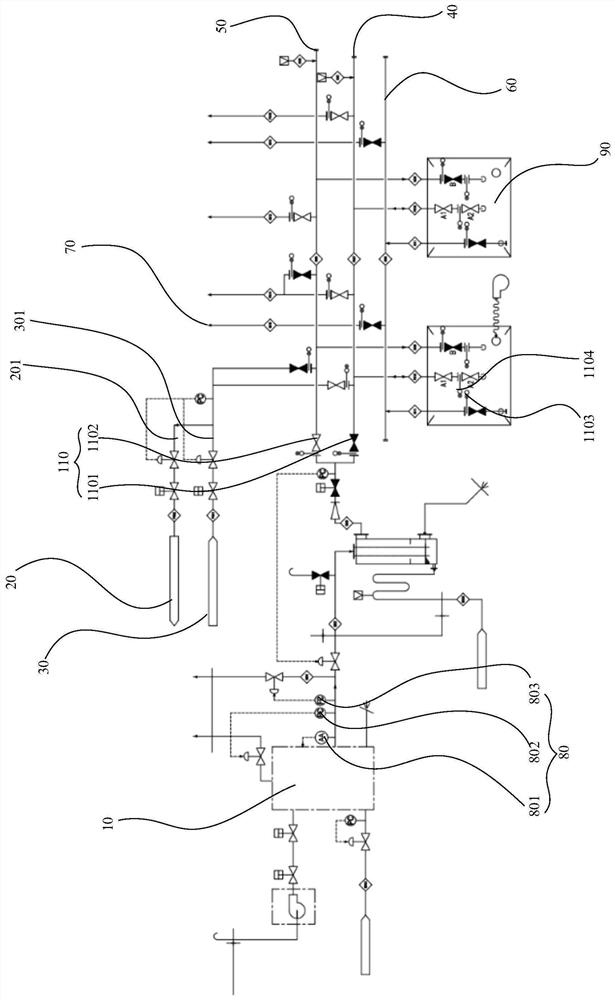

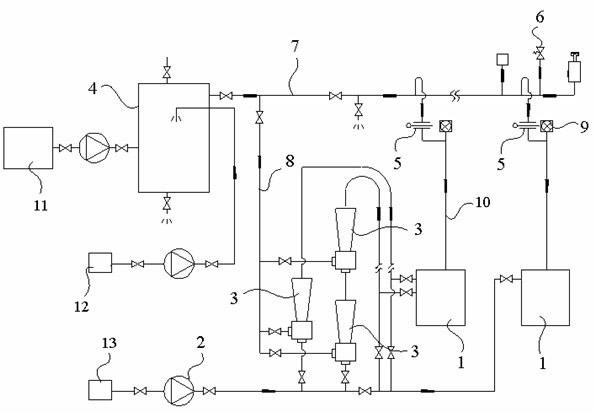

Ballast water treatment plant for ocean-going vessel

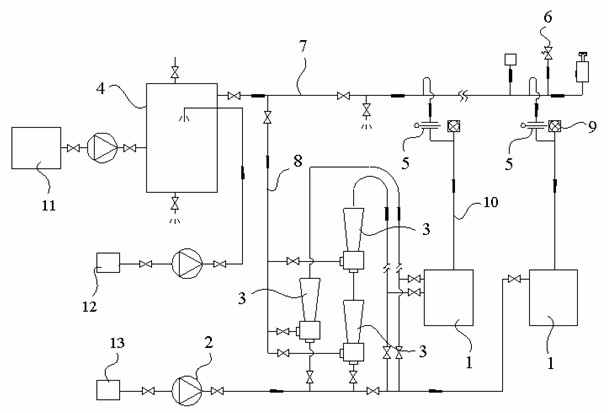

InactiveCN102501945ALow oxygenNot subject to oxidation and corrosionSelf-bailing equipments/scuppersVessel partsSocial benefitsBallast water treatment

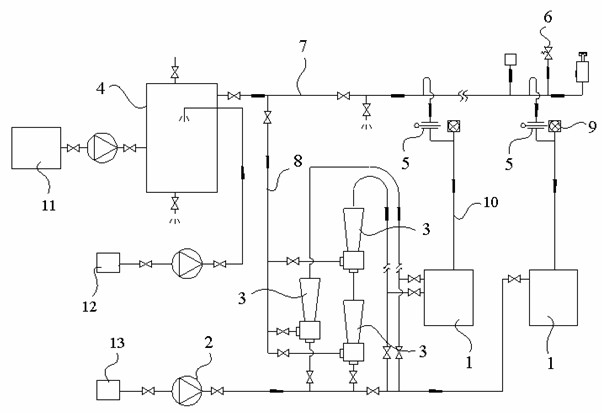

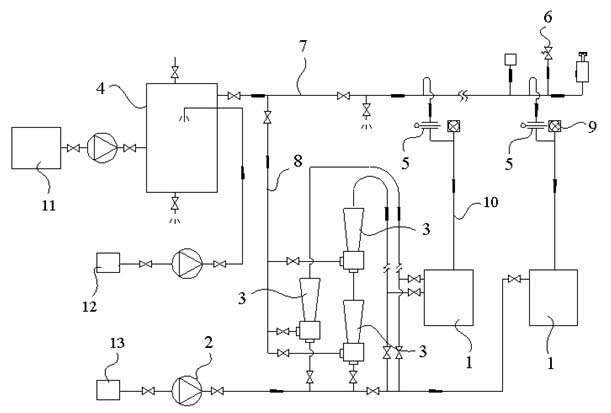

The invention discloses a ballast water treatment plant for an ocean-going vessel, which comprises ballast tanks, a ballast pump, Venturi ejectors and an inert gas generator, wherein the ballast pump is communicated with the ballast tanks, the Venturi ejectors are respectively communicated with the ballast tanks and seawater through pipelines, the inert gas generator is respectively communicated with the Venturi ejectors and the ballast tanks through pipelines, and ventilating valves are arranged on the ballast tanks. A ballast water treatment method in the plant is a physical method, and accordingly, additional chemical agents, relevant agent feeding devices and other filter devices are not needed, periodic cleaning is omitted, water flow is unaffected, drain time is shortened, the tanks are protected from oxidation corrosion, reliability of ballast water treatment effect is ensured, and the ballast water treatment plant is fine in practicality and capable of generating fine economic and social benefits.

Owner:YANGZHOU DAYANG SHIPBUILDING

Process method and device for producing oil by pyrolysis of high-molecular polymerization waste

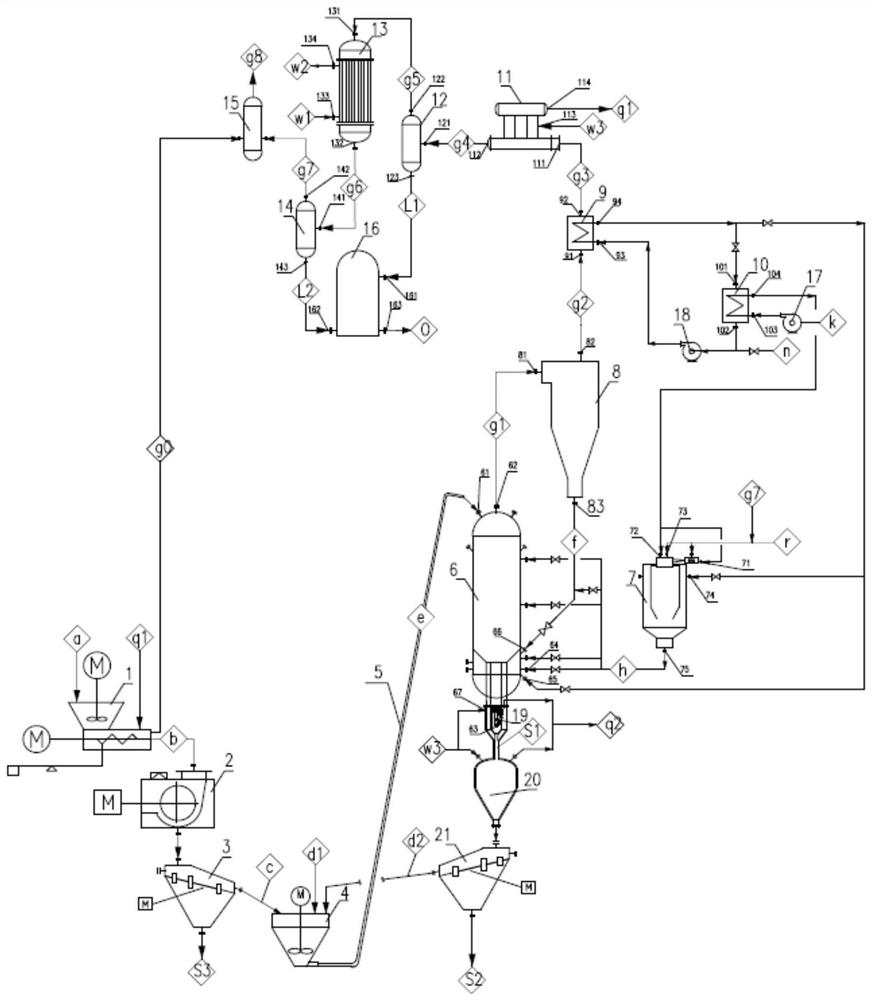

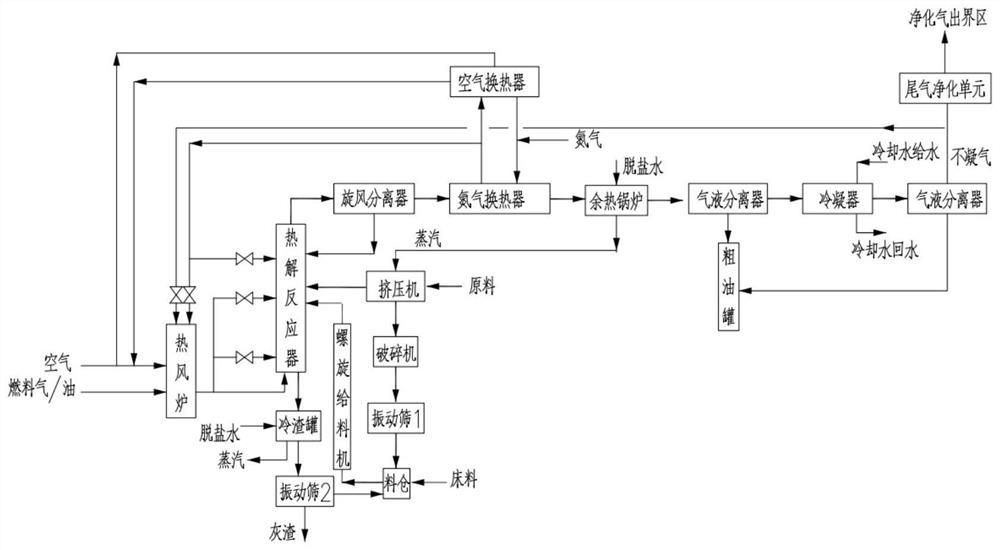

PendingCN113122300AFeeding form is flexible and convenientGuaranteed pyrolysis temperatureLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFixed bedEngineering

The invention discloses a process method and device for producing oil by pyrolysis of high-molecular polymerization waste. The process method comprises the following steps of extruding the high-molecular polymerization waste through an extruder, mixing the extruded high-molecular polymerization waste with a bed material, feeding the mixture into a fixed bed pyrolysis reactor, carrying out pyrolysis reaction, removing fly ash from the generated high-temperature oil gas through a cyclone separator, and carrying out heat exchange with nitrogen, then entering a waste heat boiler to recover heat energy, carrying out gas-liquid separation, feeding liquid into a crude oil tank to be stored, and further condensing gas to obtain crude oil, combusting fuel in the inert gas generator to generate oxygen-deficient hot air which is fed into the fixed bed pyrolysis reactor to be in full contact with the mixture, and providing heat for the pyrolysis reaction, and cooling and screening the waste residue, and recycling the bed material for reutilization. The high-molecular polymerization waste is dechlorinated and deacidified after being extruded, so that the problem of corrosivity of a reaction system caused by chlorine and acid gas generated by pyrolysis is solved, the pyrolysis temperature in the reactor is ensured by adopting a multi-section heat supply mode, and the problems of poor heat conductivity and non-uniform reaction heating of the high-molecular polymerization waste are solved.

Owner:渭沣洁净技术(上海)有限公司 +1

Coal mine inert gas foam extinguishing system

The invention inlets inert gas and foam mixed liquor to the inert foam generator, the inert foam generator is a sealed container. The inert gas and the foam mixed liquor is insulated with the air in the inert foam generator, and the produced inert foam leads to the fire district, to stifle and put out source of fire by double-isolated function ( inert gas isolation, foam isolation). The water is input into a proportioner by a transmission pipe from a pressure water source, the foam stock solution is input to the proportioner from a foam liquor storage tank, the water and the foam stock solution are mixed by the proportioner to form the foam mixed liquor, then the foam mixed liquor is input to the inert foam generator; the inert gas is input the inert foam generator by the inert gas transmission pipe, the inert gas and the foam mixed liquor are isolated with the are in the inert generator, the produced inert gas foam leads to the fire district to put out fire, the inert gas is composed of the inert gas generator and an inert gas bottle.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

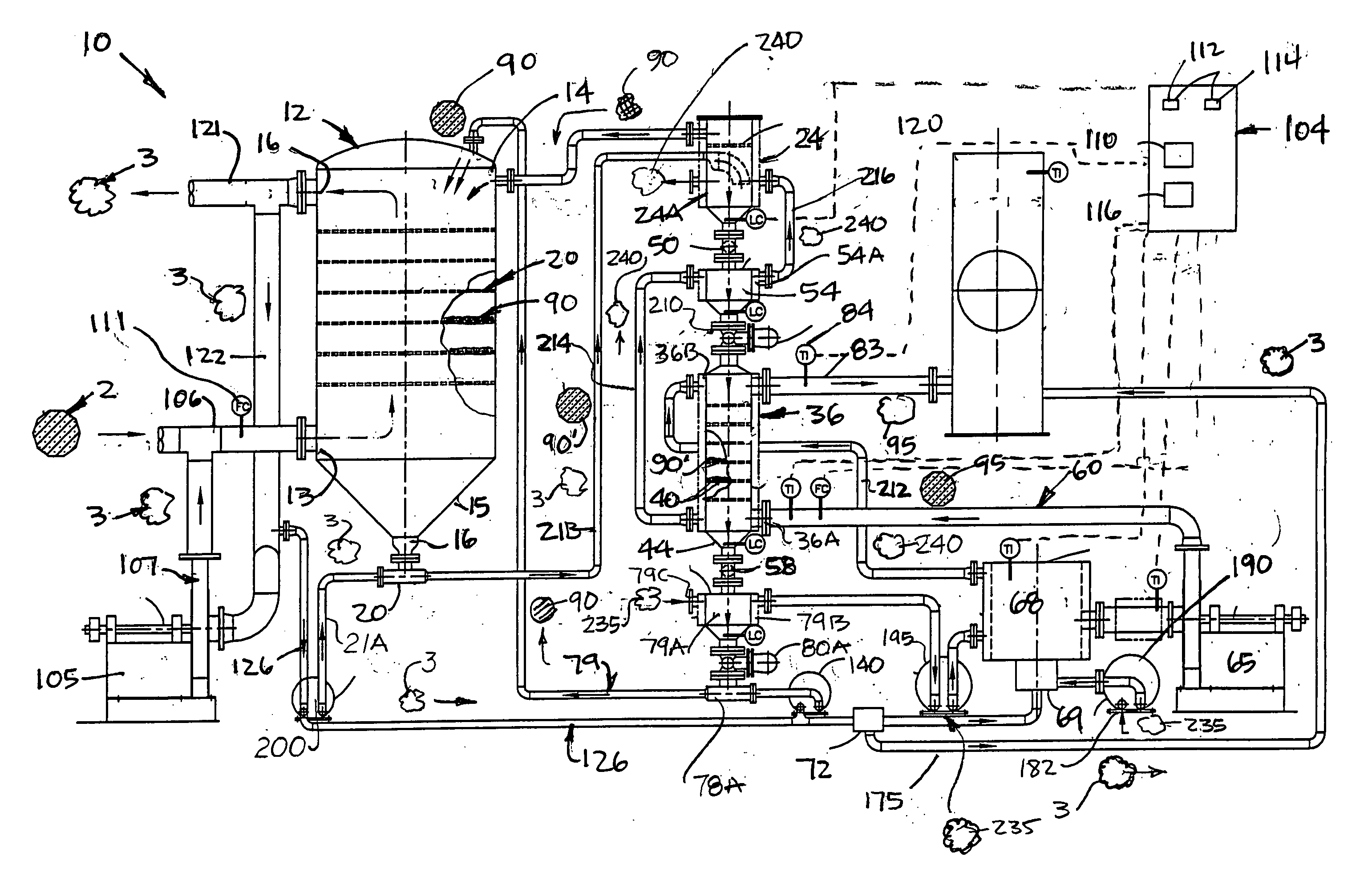

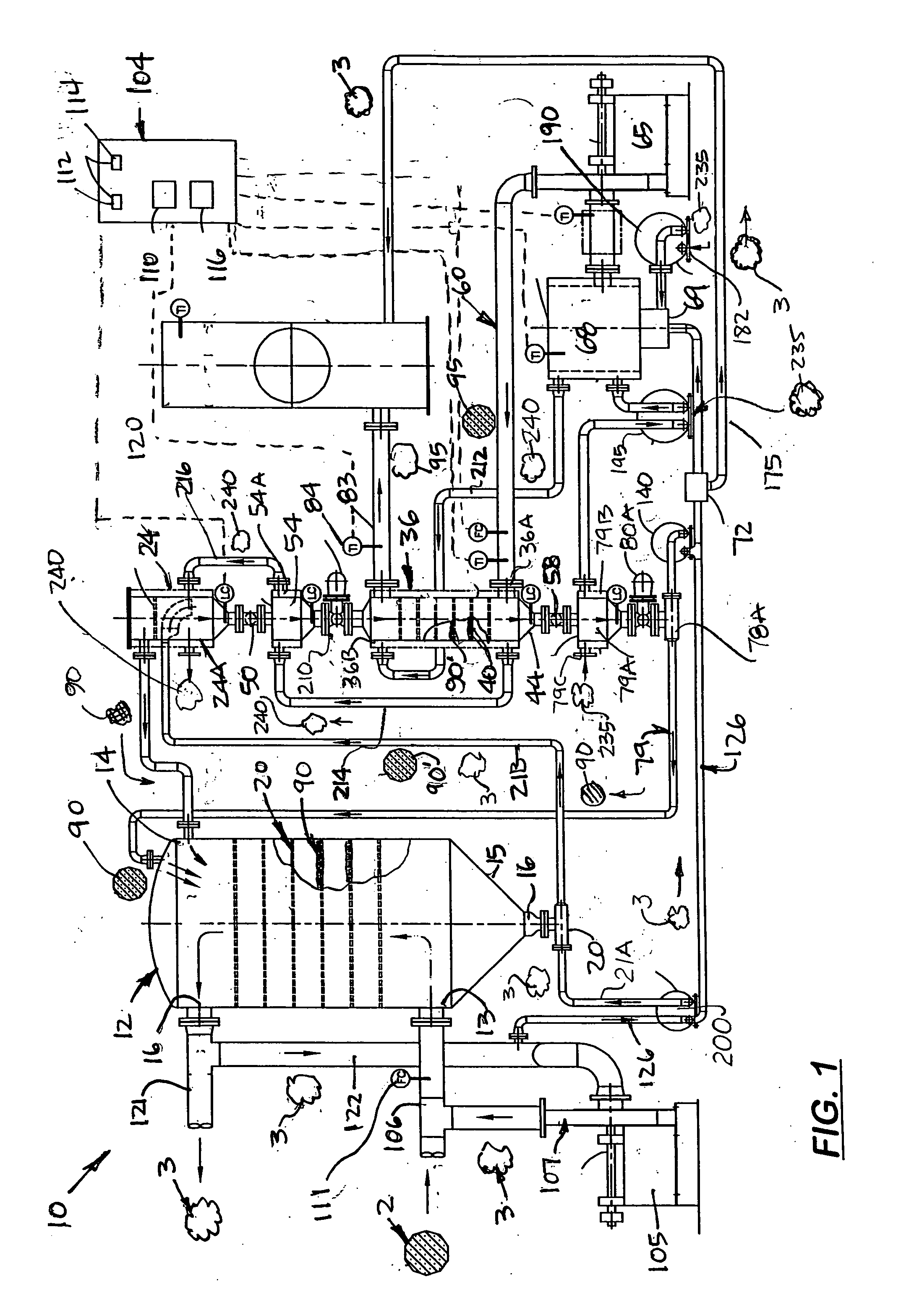

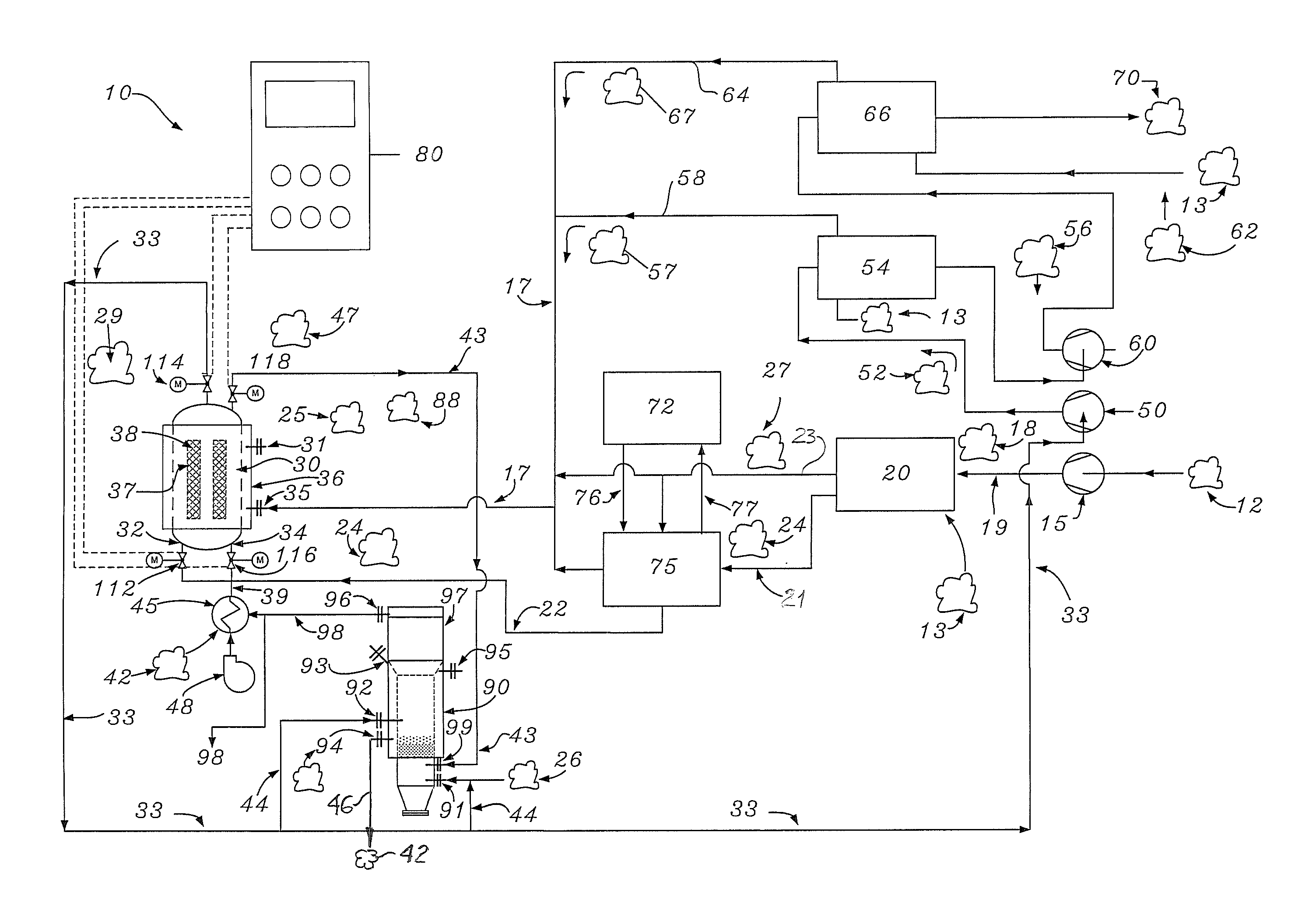

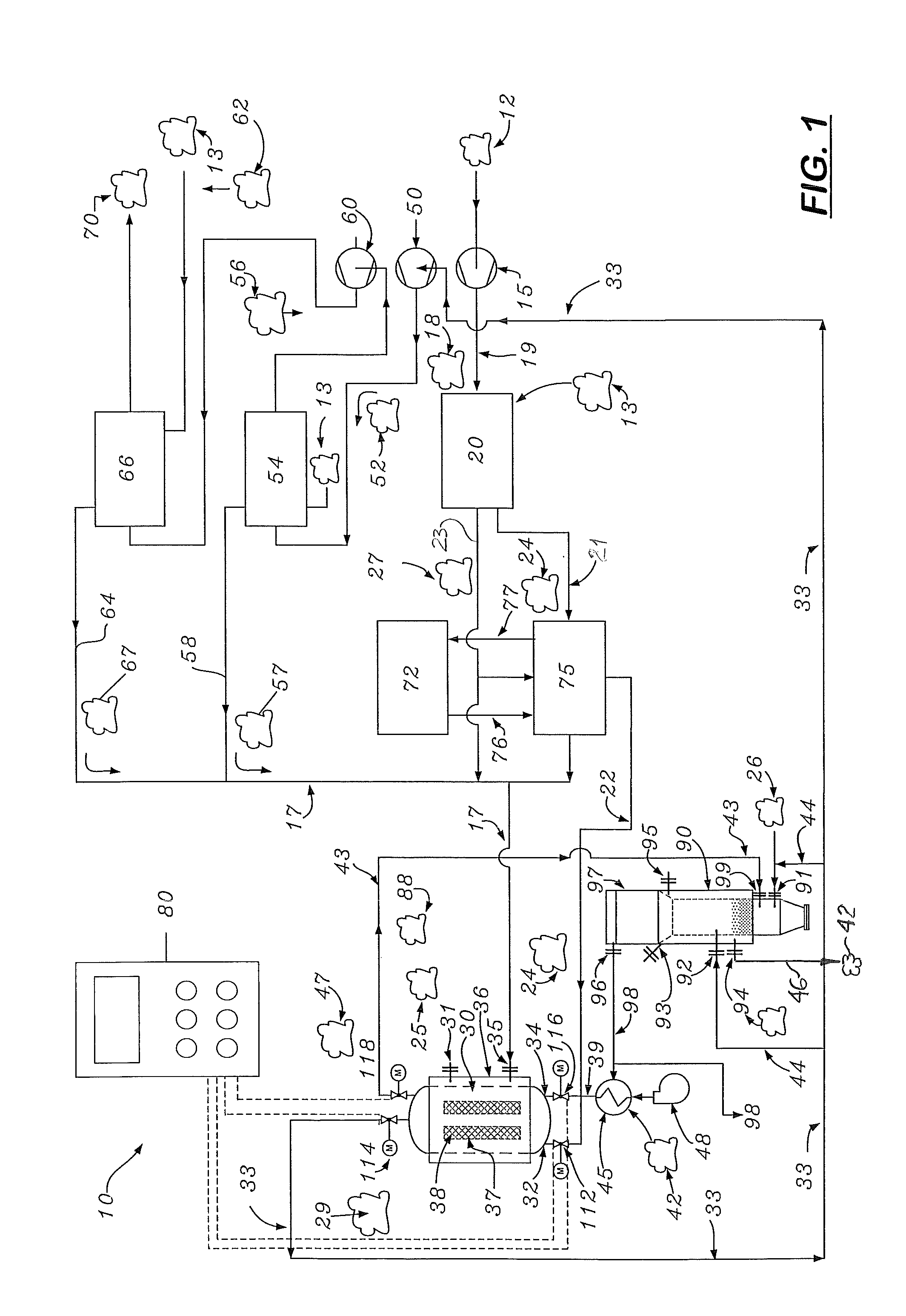

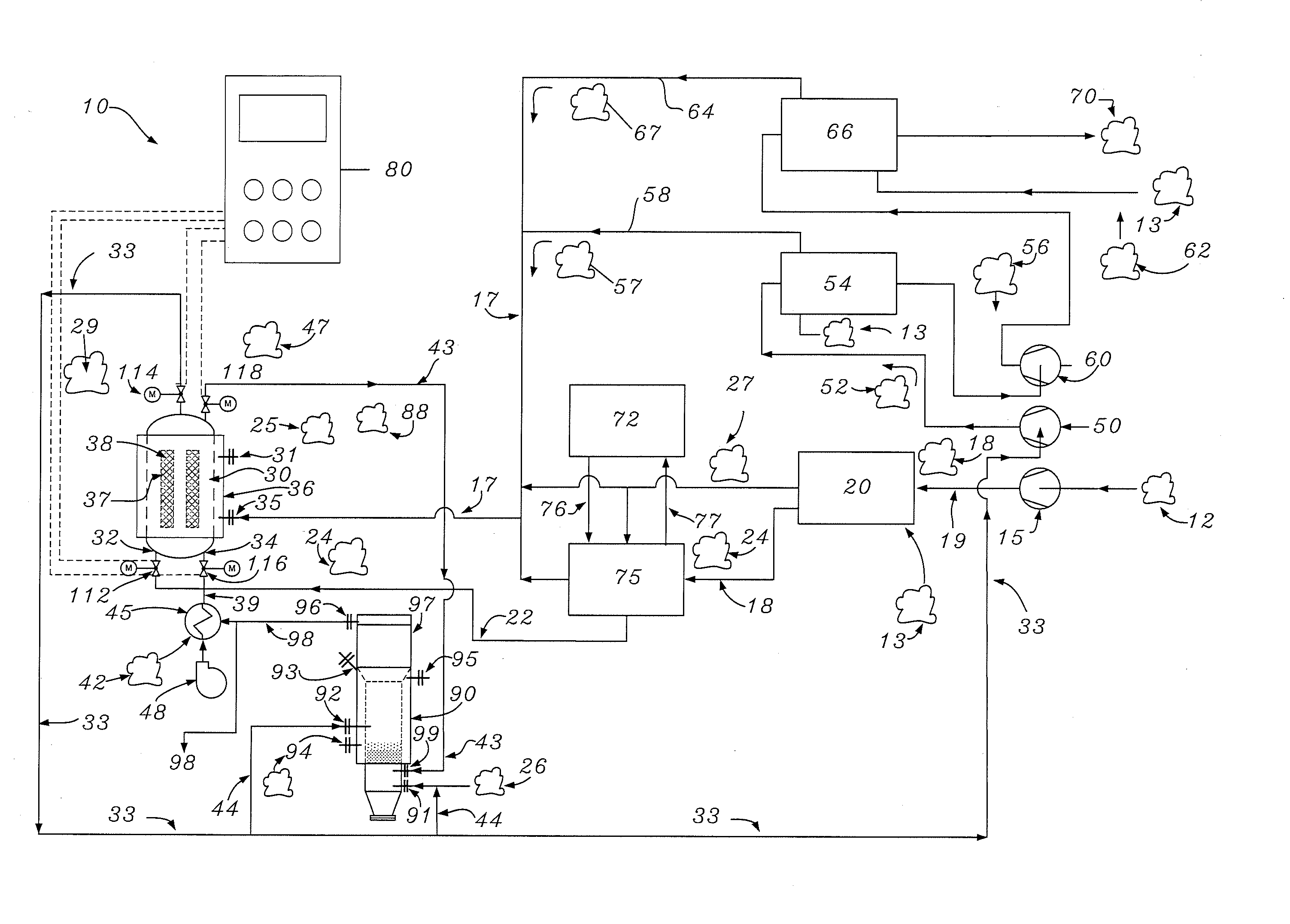

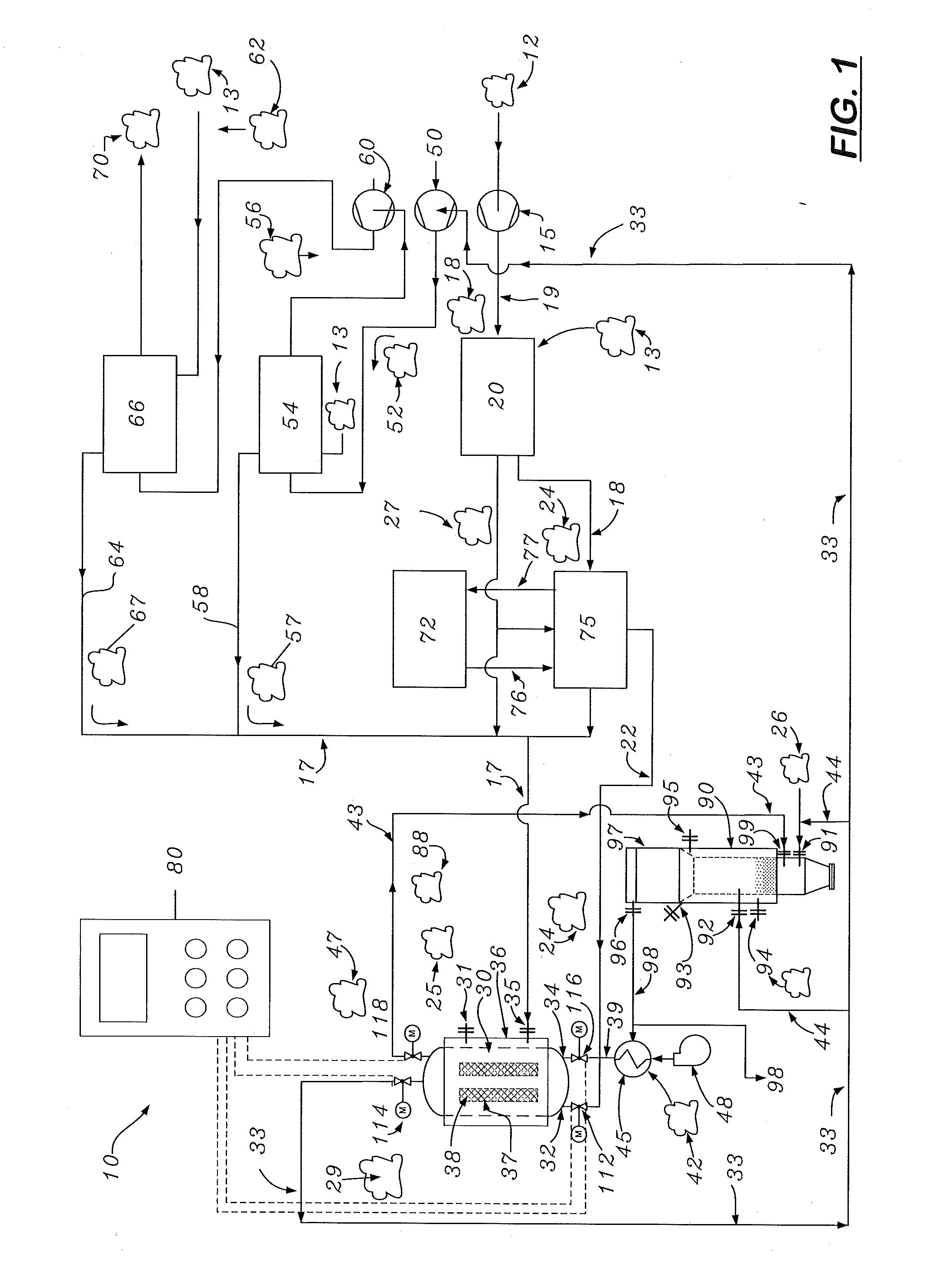

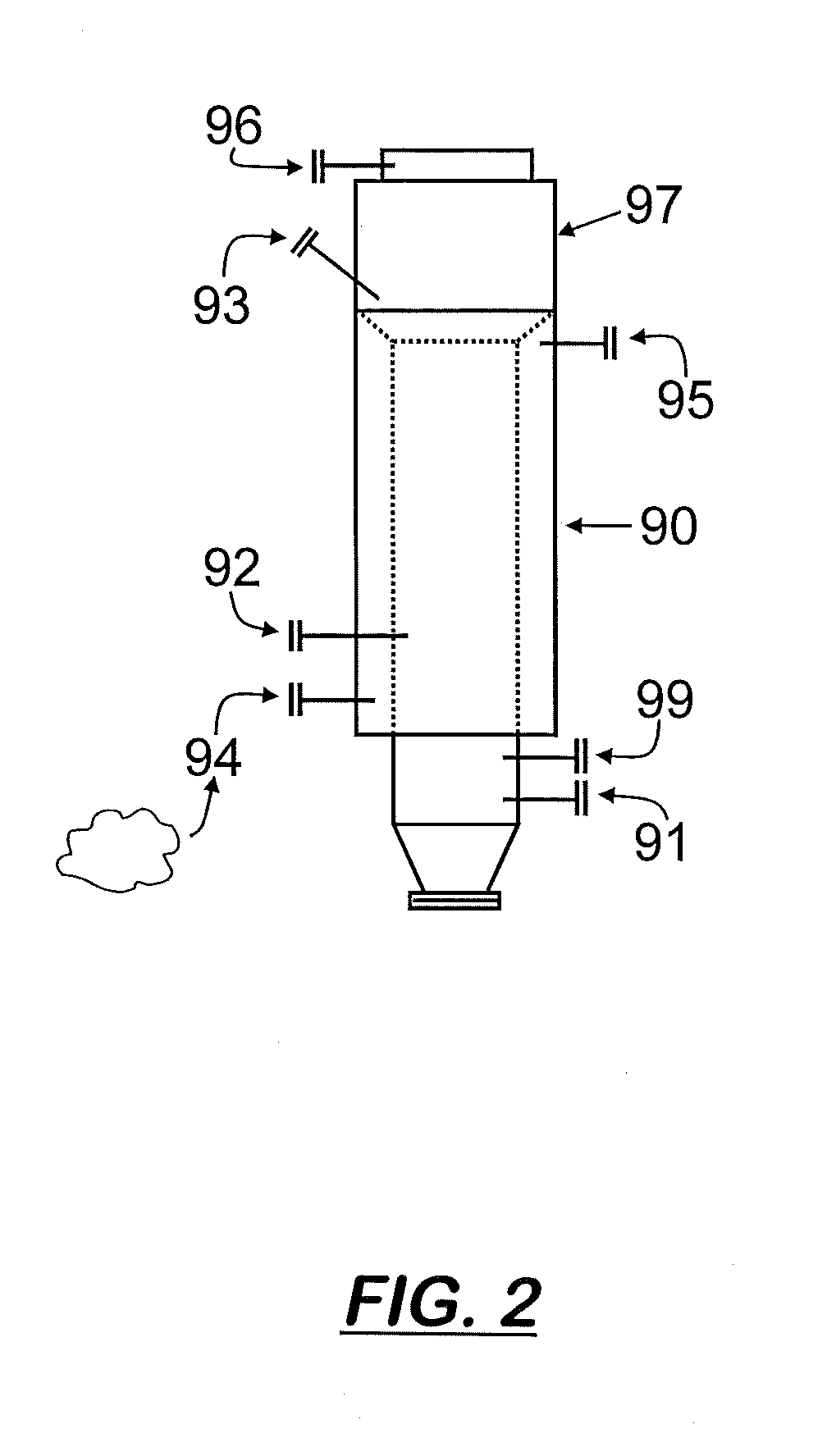

System and method extracting and employing compression heat in biogas treatment plant equipment

InactiveUS8414691B2Easy to switchShorten heating timeGas treatmentIsotope separationProcess engineeringProduct gas

The system and method for recycling and using the heat from compressed gas produced by a biogas treatment plant. The system includes a biogas cleaning stage and a plurality of compression and heat exchanger stages that allows the heat generated by compressed gases to be harvested. After the heat is harvested, it is delivered to a jacketed vessel containing media used to remove contaminants from the biogas. The media inside the jacketed vessel requires regeneration or stripping of harmful VOCs and other contaminants picked up from the biogas. The system also includes an inert gas generator that creates hot inert gas that is delivered to the jacketed vessel that heats the media located therein to remove contaminants. Because the jacket vessel and the media are simultaneously heated, the system's heat-up time is reduced The system also includes a heat exchanger that partially recovers the heat from the inert gas.

Owner:SNAP ENERGY SYST

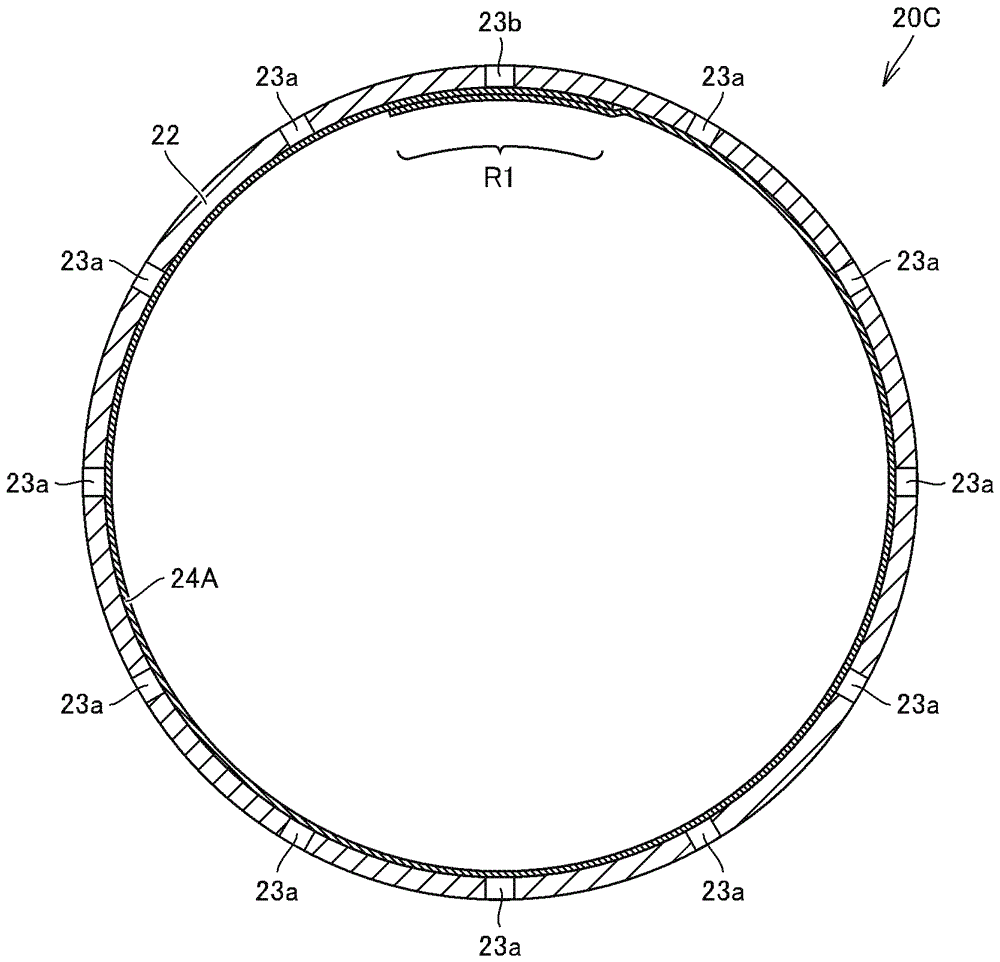

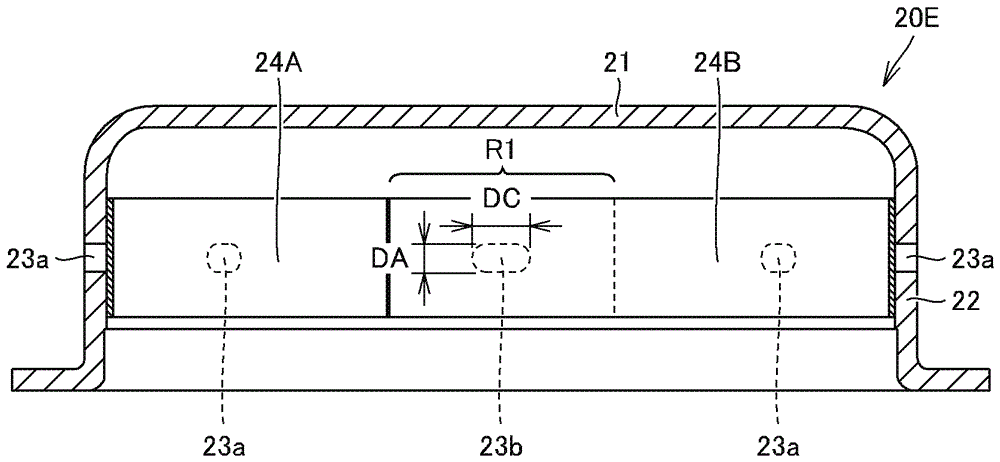

Gas generator

InactiveCN106458139ADifference in breaking strengthPedestrian/occupant safety arrangementGas generation devicesCombustionBand shape

A gas generator comprises a cylindrical partition wall section (22) provided with gas passage holes (23a, 23b) through which gas generated by the combustion of a gas generation agent passes. Two band-shaped seal tapes (24A, 24B) are continuously adhered to the partition wall section (22) so that: the direction of extension of each of the seal tapes (24A, 24B) coincides with the circumferential direction of the partition wall section (22); and a pair of ends of each of the seal tapes (24A, 24B), the pair of ends being located in the direction of extension of the seal tape, overlaps the adjacent seal tape. The gas passage holes (23b) are closed by overlapping adhesion regions (R1, R2), which are the portions where the adjacent seal tapes (24A, 24B) overlap each other, and the gas passage holes (23a) are closed by non-overlapping adhesion regions, which are the portions where the adjacent seal tapes (24A, 24B) do not overlap each other.

Owner:NIPPON KAYAKU CO LTD

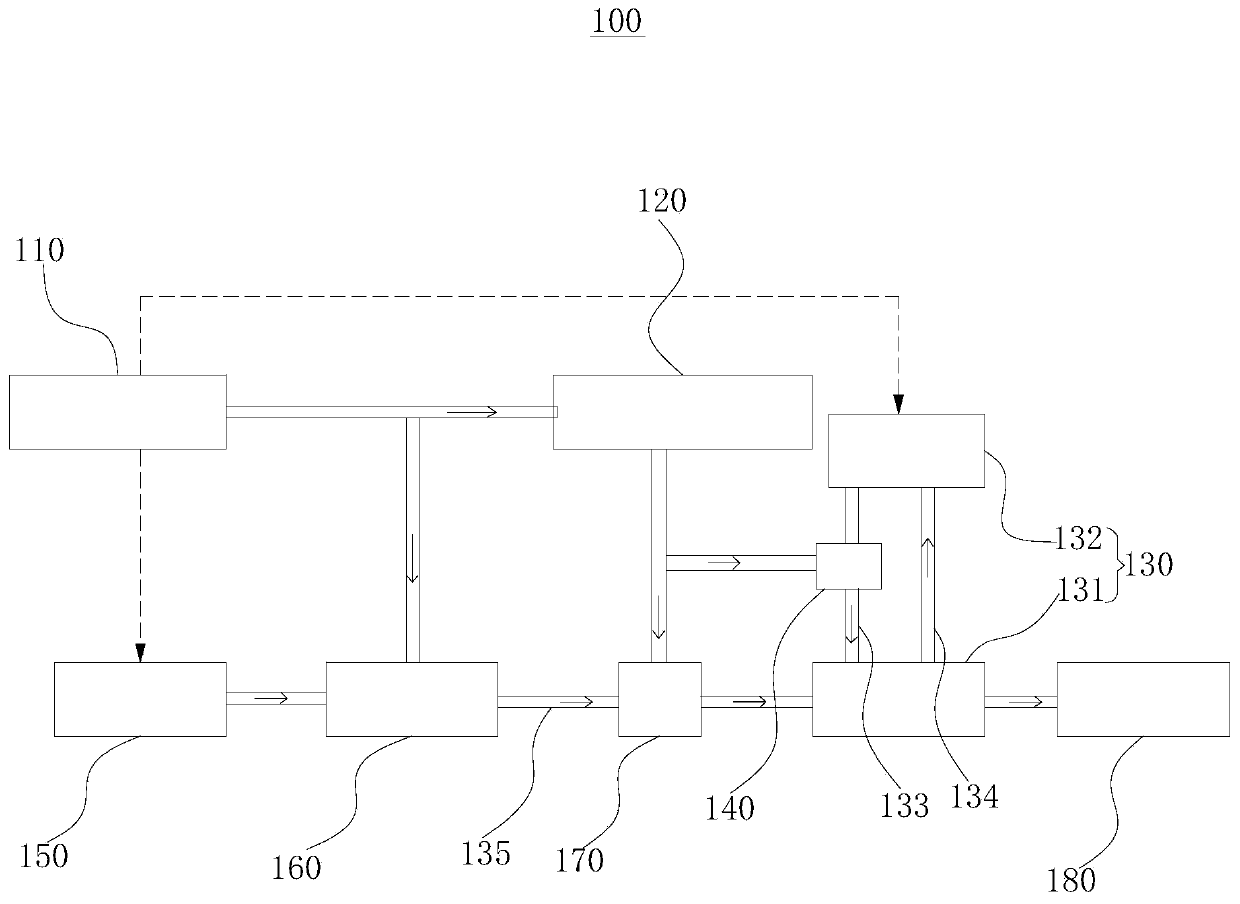

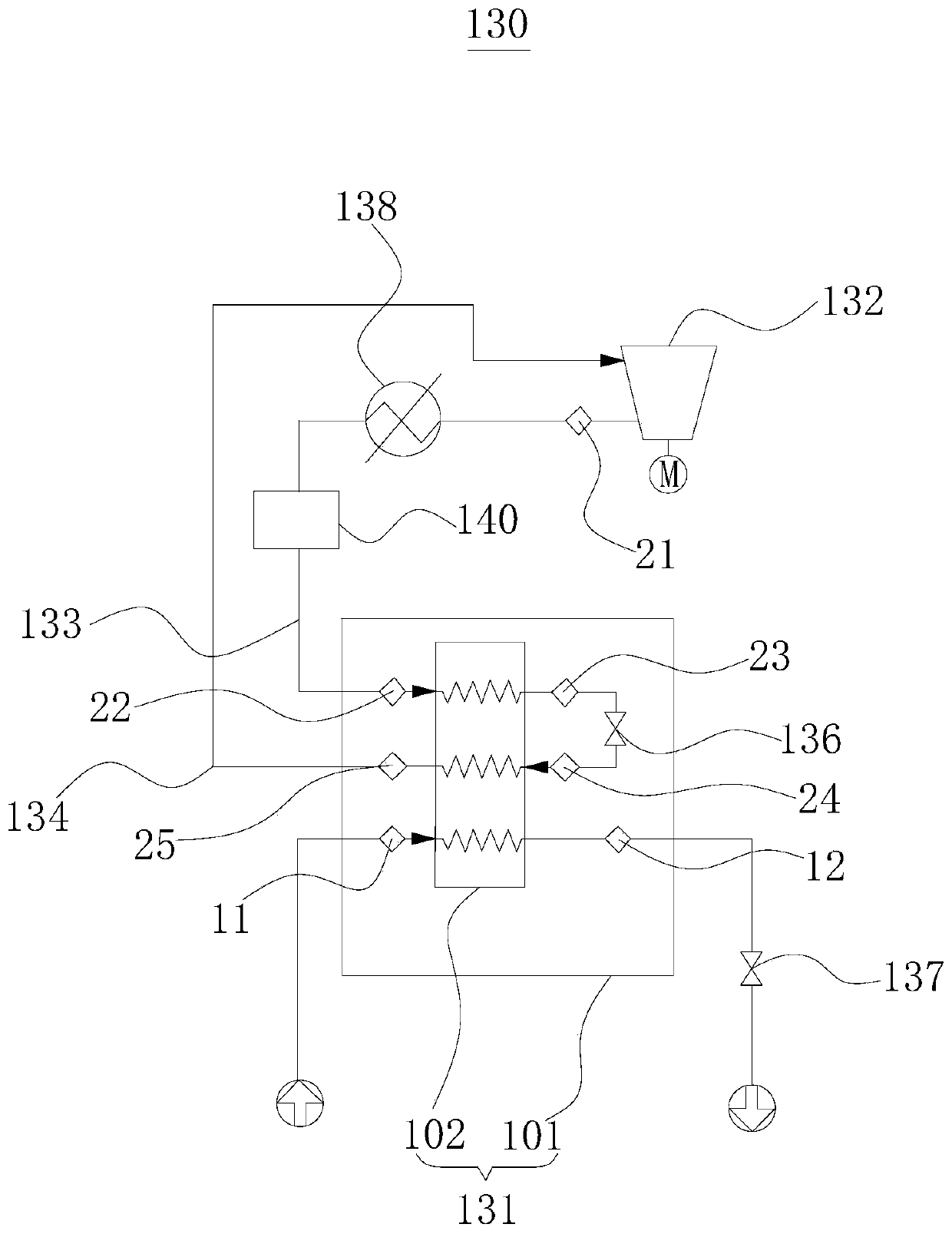

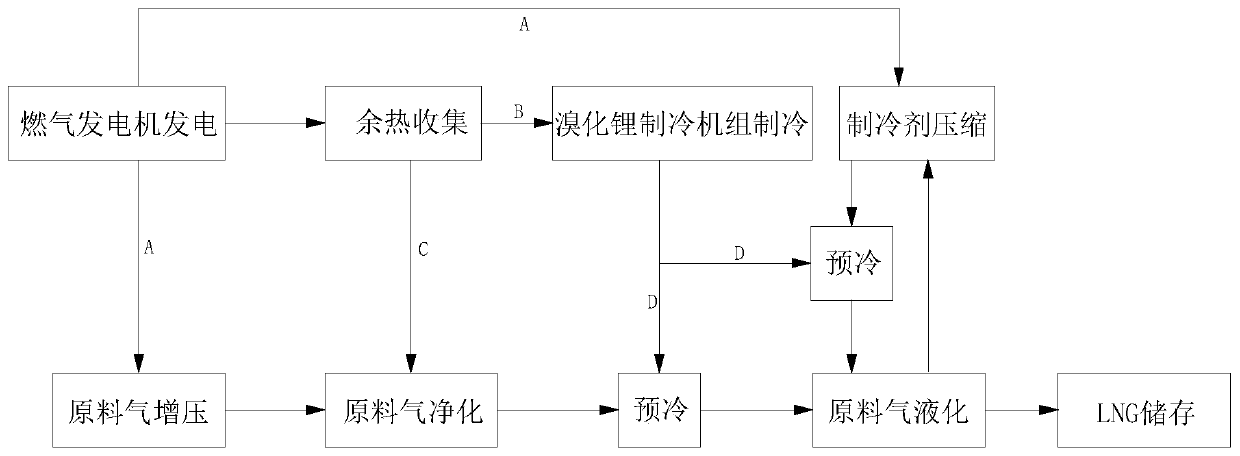

Natural gas liquefaction method and system combined with distributed energy

ActiveCN106123486BImprove operating rateReduce consumptionSolidificationLiquefactionPre coolingRefrigeration plant

The invention relates to a natural gas liquefaction method combined with distributed energy, supplying waste heat generated by the gas generator to a refrigeration unit; using the refrigeration unit to cool the circulating refrigerant and / or The raw material gas is pre-cooled; the raw material gas and the circulating refrigerant are heat-exchanged in the natural gas liquefaction device to obtain liquefied natural gas. The present invention also relates to a natural gas liquefaction system combined with distributed energy, including a gas generator, a refrigeration unit, and a natural gas liquefaction device, the power supply line of the gas generator is connected to the natural gas liquefaction device, and the gas generator passes through The pipeline is connected to the refrigerating unit, and the refrigerating unit is connected to the natural gas liquefaction device. The natural gas liquefaction method and system well combine distributed energy with a natural gas liquefaction device, improve energy utilization efficiency, and achieve the purpose of energy saving and emission reduction.

Owner:CHENGDU SEPMEM SCI & TECH

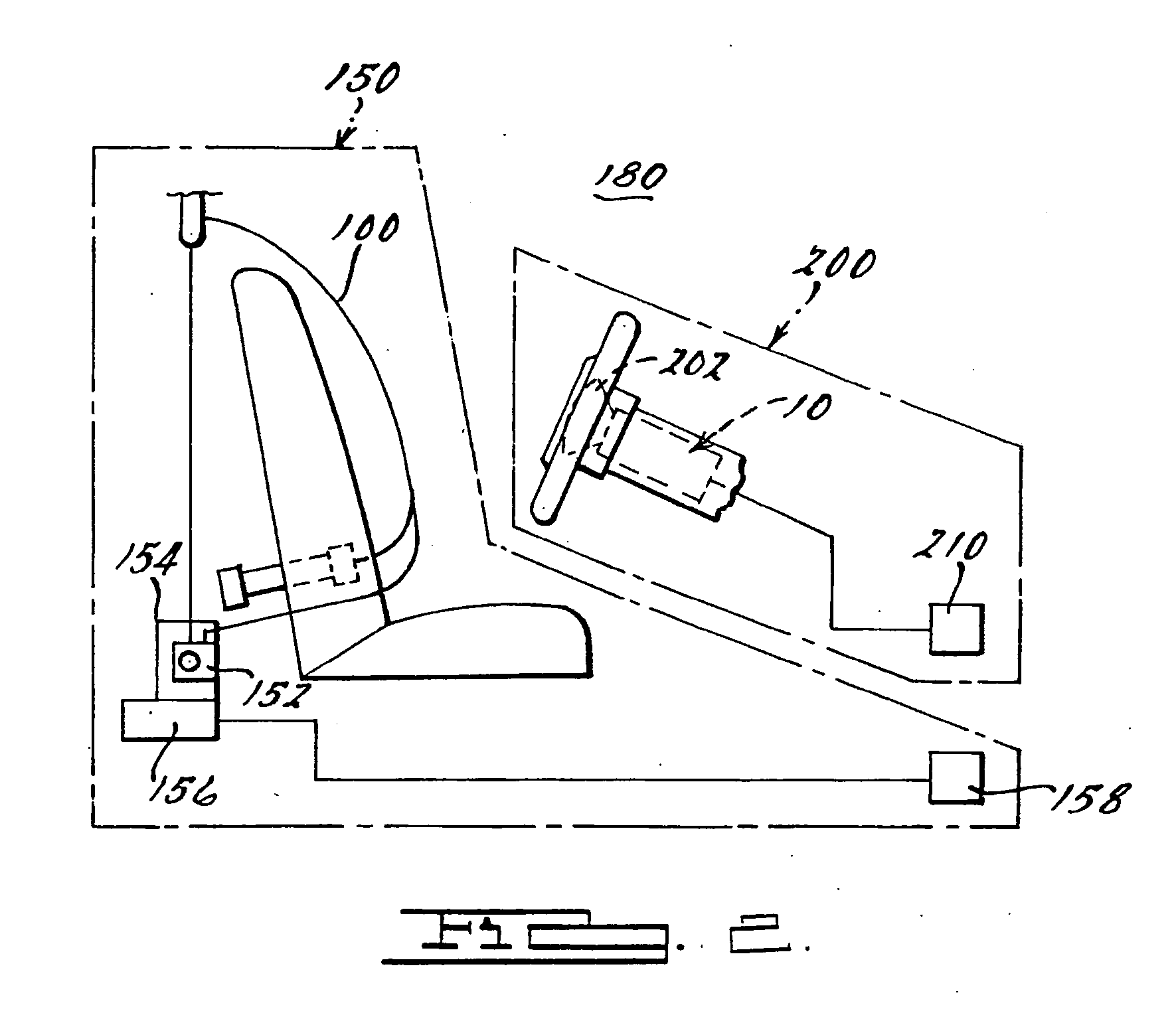

System and Method Extracting and Employing Compression Heat in Biogas Treatment Plant Equipment

InactiveUS20110005393A1Shorten heating timeShorten cycle timeGas treatmentIsotope separationProcess engineeringInert gas generator

The system and method for recycling and using the heat from compressed gas produced by a biogas treatment plant. The system includes a biogas cleaning stage and a plurality of compression and heat exchanger stages that allows the heat generated by compressed gases to be harvested. After the heat is harvested, it is delivered to a jacketed vessel containing media used to remove contaminants from the biogas. The media inside the jacketed vessel requires regeneration or stripping of harmful VOCs and other contaminants picked up from the biogas. The system also includes an inert gas generator that creates hot inert gas that is delivered to the jacketed vessel that heats the media located therein to remove contaminants. Because the jacket vessel and the media are simultaneously heated, the system's heat-up time is reduced The system also includes a heat exchanger that partially recovers the heat from the inert gas.

Owner:SNAP ENERGY SYST

Method and device for remediation of persistent organic pollutant-contaminated soil

ActiveCN103272838BAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

System for inerting at least one volume in an aircraft via at least one fuel cell

InactiveUS20200171429A1Purity of the inert gas remains substantially constantReduce water contentPower installationsAir-treatment apparatus arrangementsAutomotive engineeringInert gas generator

A system for inerting at least one volume in an aircraft includes at least one generator of inert gas fed with compressed air originating from a passenger cabin, and means for distributing the inert gas into the volume to be rendered inert, which are connected to the generator of inert gas. According to the invention, the generator of inert gas comprises a fuel cell including an outlet of oxygen-depleted gas connected to means for drying said gas.

Owner:SAFRAN AEROTECHNICS SAS

Gas generator

ActiveCN104593084AWide range of load adjustmentFlexible and convenient load adjustmentGranular/pulverulent flues gasificationEngineeringProcess engineering

The invention provides a gas generator which comprises a plurality of entrained-bed reaction furnaces and a heat exchange boiler, wherein the plurality of entrained-bed reaction furnaces are respectively and fixedly arranged on the top of the heat exchange boiler; each entrained-bed reaction furnace is internally provided with an entrained-bed reaction chamber; the upper part of each entrained-bed reaction furnace is provided with a pulverized coal gasification burner communicated with the interior of the corresponding entrained-bed reaction chamber; the entrained-bed reaction chambers of all the entrained-bed reaction furnaces are respectively communicated with the interior of the heat exchanger boiler. The gas generator is wide in load adjustment range, flexible and convenient in load adjustment, high in reliability and low in cost.

Owner:KEDA MAS CLEAN ENERGY

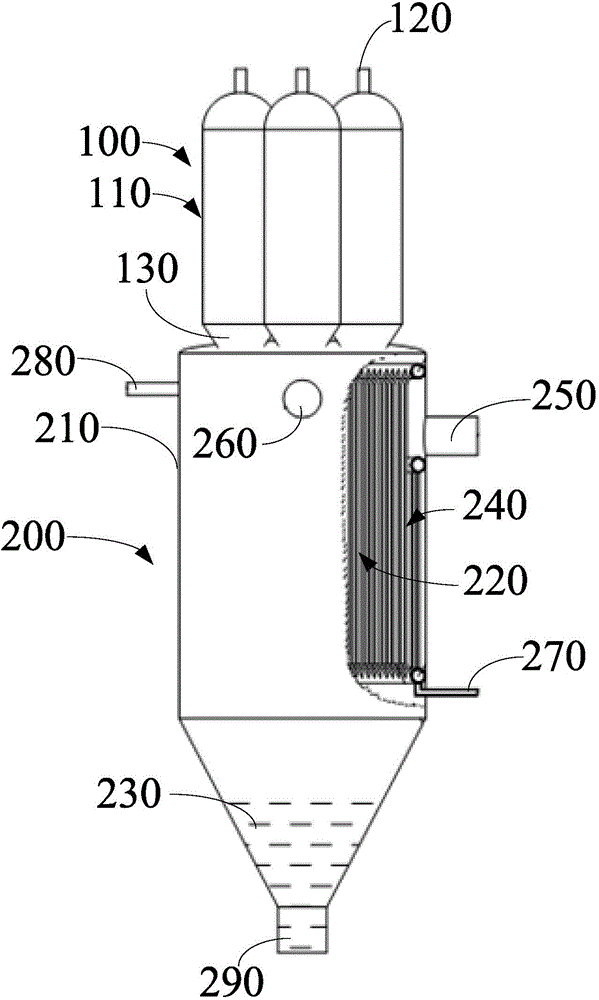

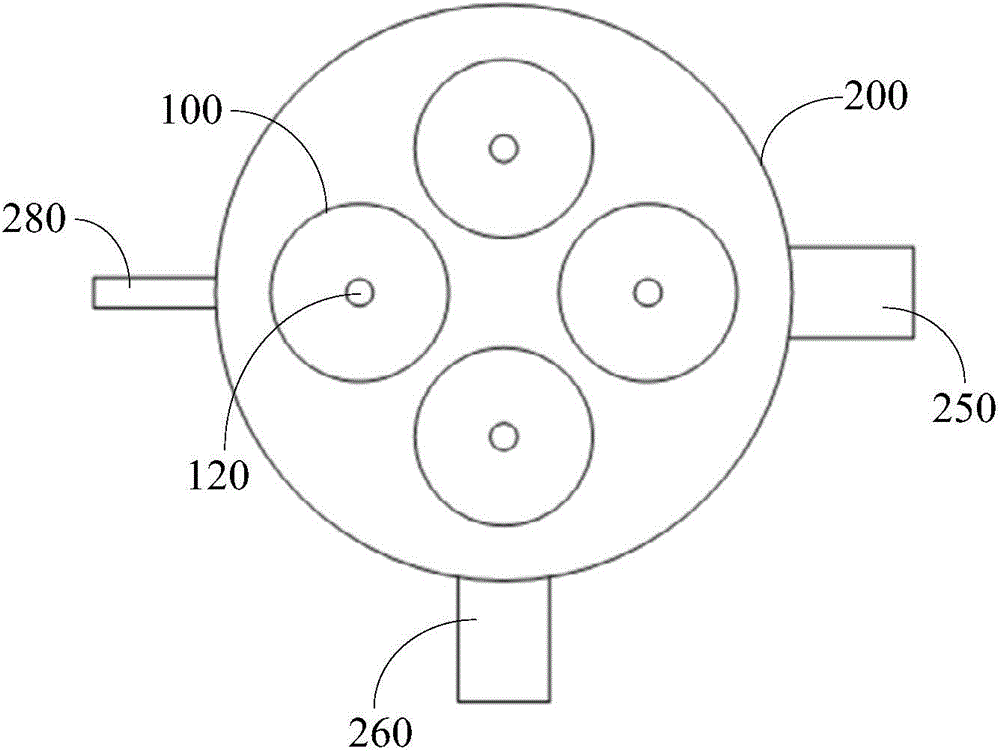

Environmentally-friendly efficient graphite purifying apparatus

InactiveCN105776184AGuaranteed high temperature performanceImprove purification efficiencyChemical industryInsulation layerGraphite

The invention discloses an environmentally-friendly efficient graphite purifying apparatus. The apparatus is characterized in that the inner wall of a reaction kettle (1) is provided with a heat insulation layer (3), a heater (4) is arranged in the heat insulation layer (3), the upper end of a purifying furnace (17) is provided with an acid feeding hole (10), the acid feeding hole (10) is provided with an acid solution flow meter (11), the lower end of the purifying furnace (17) is provided with a tail gas discharge opening (7), the tail gas discharge opening (7) is connected with an acid mist absorption tower (5) through a tail gas conveying pipeline (6), a water outlet tube (8) and a water inlet tube (16) are arranged between the inner liner and the outer wall of the purifying furnace (17), the water outlet tube (8) and the water inlet tube (16) are respectively connected with a heater (9) to form a water current loop, and an inert gas generator (15) is arranged above the cavity of the purifying furnace (17). The apparatus has the advantages of heat insulation, energy saving and high purifying efficiency, and allows the purity to reach 99.996% or above.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

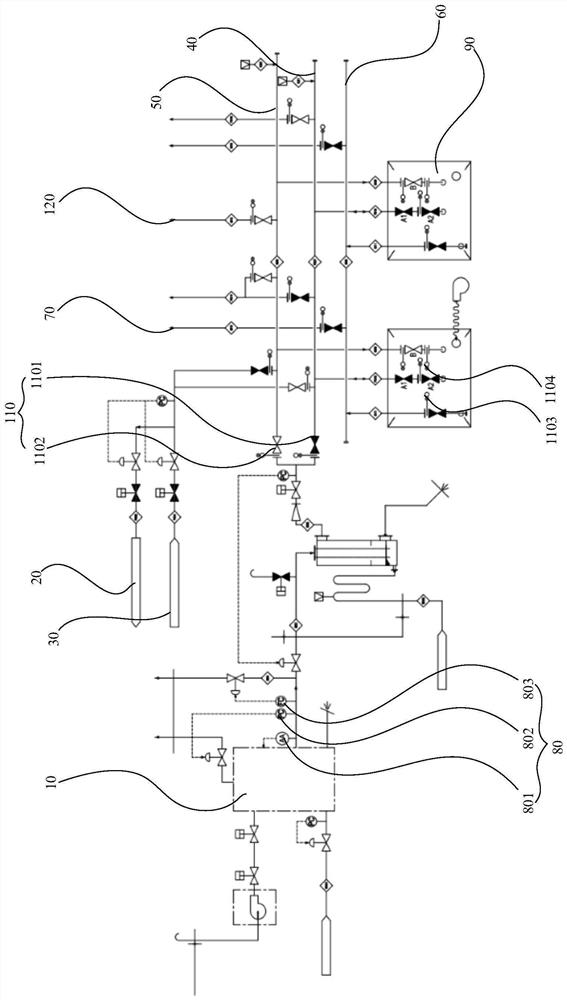

Crude oil cargo hold ventilation system and offshore floating production oil storage ship comprising same

InactiveCN111891327AReduce oxygen contentReduce dosageAuxillariesVessel ventillation/heating/coolingExhaust fumesGas supply

The invention discloses a crude oil cargo hold ventilation system and an offshore floating production oil storage ship comprising the crude oil cargo hold ventilation system. The crude oil cargo holdventilation system comprises an inert gas generator and a hydrocarbon gas supply device, wherein the inert gas generator is communicated with a cargo hold through a pipeline. The crude oil cargo holdventilation system further comprises the hydrocarbon gas supply device which is communicated with the cargo hold through a pipeline. The inert gas generator and the hydrocarbon gas supply device are communicated with the cargo hold, so that the cargo hold not only can replace air in the cargo hold through inert gas generated in the inert gas generator, that is, oxygen in the cargo hold is reduced,but also can input hydrocarbon gas into the cargo hold to replace inert gas with hydrocarbon gas, so that the oxygen content in the cargo hold is always lower than a critical value causing explosion,and the purpose of protecting the cargo hold is achieved. By adopting the structure, the use amount of inert gas can be reduced, on the one hand, the cost can be saved, and on the other hand, waste gas discharged in the inert gas generation process can be reduced.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Petrol station buried tank cleaning system

PendingCN106944443AAvoid wastingReduce consumptionSludge treatment by de-watering/drying/thickeningHollow article cleaningProcess engineeringSewage

The invention discloses a petrol station buried tank cleaning system. The petrol station buried tank cleaning system comprises a buried tank, a cleaning recycling device, a cleaning machine, an oil-water separation device, a sludge dewatering machine, a reaction tank, an air flotation machine, a filtering device, a cleanser adding device, an inert gas generator and a vacuum pump, wherein the lower portion of the buried tank is provided with a water discharging valve and an outlet which are connected in the cleaning recycling device through recycling pipelines. According to the petrol station buried tank cleaning system, cleaned oil products can be reused, waste of oil products is prevented, and the resource reutilization rate is greatly improved. Sewage is recycled, the whole cleaning system becomes a closed cycle system, consumption of cleaning water is reduced, cleaning efficiency is high, and the environment is protected.

Owner:成都佳辉蓉达环保科技有限公司

Two-stage air-lock air locking system and air locking method thereof

The invention relates to a two-stage air-lock air locking system and an air locking method thereof. The air locking system comprises a two-stage air lock body connected with a material storage device, an inert gas generator, a driving system and a pressure control system, the two-stage air lock body is connected with the driving system, the inert gas generator is connected with the pressure control system and then simultaneously connected to the material storage device and the two-stage air lock body, two-three stainless-steel spring steel sheets are mounted on blades of air locks, are in flaky arrangement and are overlapped on the inner wall of housings of the air locks in an arc manner. The system is better in sealing property and wide in applicable temperature range; particularly, leakage of on-site toxic and harmful gases can be reduced greatly, and physical and mental health of workers is protected.

Owner:JIANGSU CHINA NUCLEAR IND HUAWEI ENGDESIGN & RES

Oceangoing vessel ballast water processing method

InactiveCN102502906ALow oxygenEasy maintenanceWater/sewage treatment by flotationSocial benefitsEconomic benefits

The invention discloses an oceangoing vessel ballast water processing method. According to the method, air over the ballast water in ballast water chambers is evacuated by an inert gas, the ballast water in the ballast chambers is pumped out of the ballast chamber, the ballast water is subjected to blow-off mixing by the inert gas to generate a physical reaction, a soluble inert gas is merged into the ballast water when oxygen in the ballast water is sucked out, and the processed ballast water is discharged into the ballast water chambers. A device of the method comprises the ballast chambers, ballast pumps, Venturi ejectors and an inert gas generator. The ballast water processing method of the invention, which is a physical method, needs no extra chemical agents or relevant dosing devices; the physical reaction can be directly generated in the Venturi ejectors, and no filter devices are needed before the reaction generation, so time-cost regular cleaning is not needed, the water flow is not influenced, the discharge time is reduced, and the chambers are protected from oxidation corrosion, thereby the reliability of the ballast water processing effect is guaranteed; and the method of the invention, which has a very good practicality, can generate very good economic benefits and social benefits.

Owner:YANGZHOU DAYANG SHIPBUILDING

High-moisture brown coal pulverizing and drying apparatus and method thereof

ActiveCN103146454BImprove sealingImprove adaptabilityDrying solid materials with heatDrying gas arrangementsFluidized bed dryingBrown coal

The invention provides a high-moisture brown coal pulverizing and drying apparatus and a method thereof. The brown coal pulverizing and drying apparatus is characterized in that the apparatus comprises a fluidized bed dryer, the fluidized bed dryer is connected with a deduster, the deduster is connected with the inlet of a mixer, the deduster is connected with a low pressure steam heater, a fluidization fan and a booster fan, the fluidization fan is connected with the fluidized bed dryer, the booster fan is connected with the steam coil tube of the fluidized bed dryer, the fluidized bed dryer is connected with the inlet of the mixer, the mixer is connected with a coal pulverizer, the coal pulverizer is connected with a pulverized coal filter, the pulverized coal outlet of the pulverized coal filter is connected with a pulverized coal cabin, the gas outlet of the pulverized coal filter is connected with a circulating fan, the circulating fan is connected with a divider, the divider is connected with the low pressure steam heater, the low pressure steam heater is connected with an inert gas generator, and the inert gas generator is connected with the coal pulverizer. The apparatus and the method are suitable for the drying and the pulverizing of coals comprising high-moisture brown coal and the like, and the particle size distribution and the water content of the prepared pulverized coal are adapted to requirements of a vaporizing furnace.

Owner:SHANGHAI BOILER WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com