Gas generator

一种气体发生器、气体通道的技术,应用在气体发生装置、化学仪器和方法、车辆安全安排等方向,能够解决压力升高、气体流动困难、不能容易地燃烧全部气体发生剂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

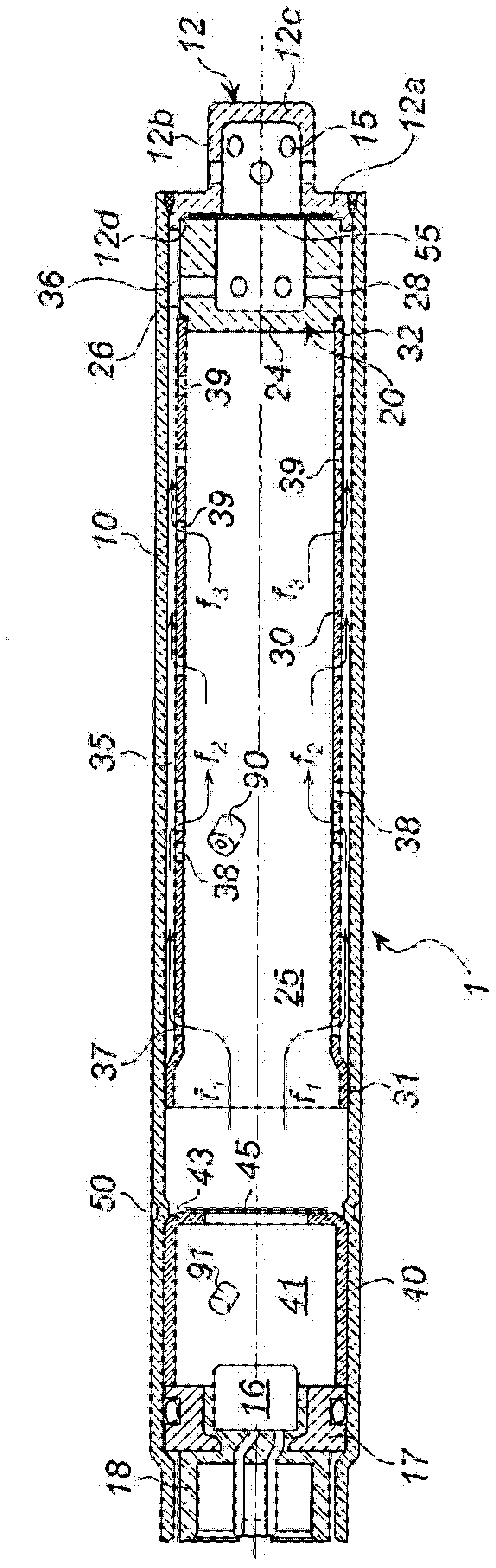

[0043] (1) figure 1 gas generator

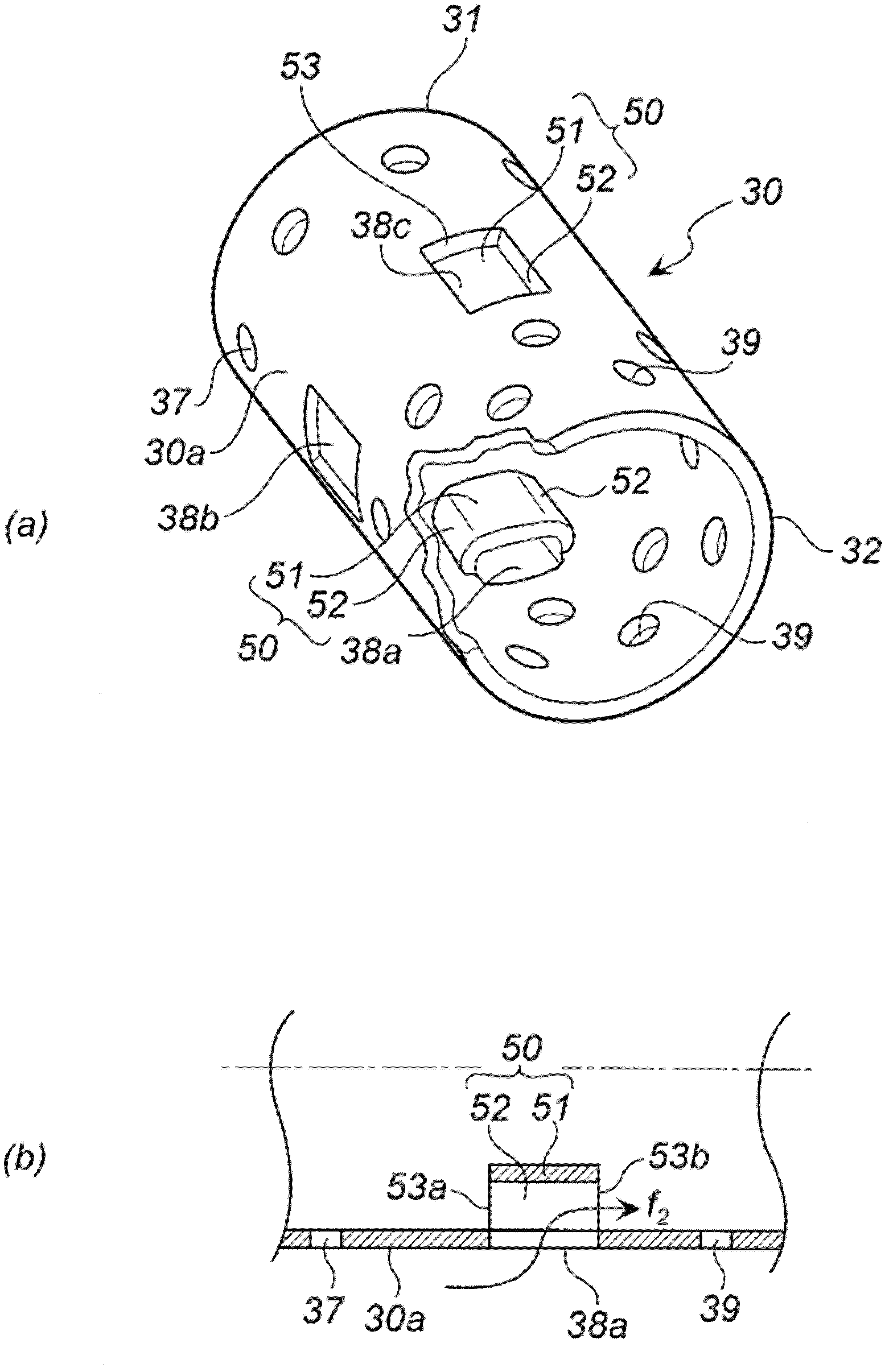

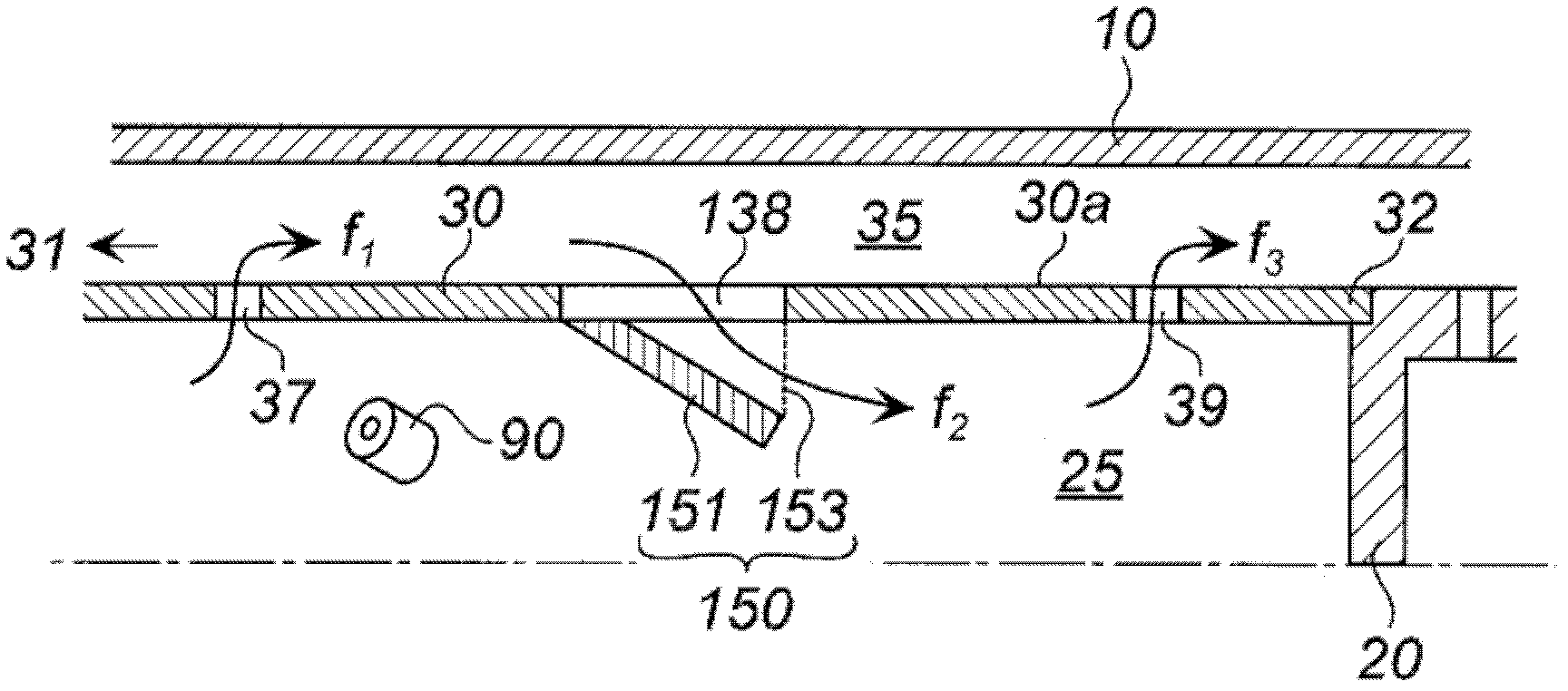

[0044] refer to figure 1 Examples of the present invention will be described. figure 1 is a sectional view of the gas generator 1 along the axial direction. However, it is worth noting that, figure 1 Do not show figure 2 The protruding portion 50 of the tubular element is shown in .

[0045] Ignition means including an igniter 16 and a first gas generating agent 91 are connected to one end of the tubular housing 10 . The first gas generating agent 91 is used as a propagating agent. The igniter 16 is bonded together with a metal igniter collar 17 by resin 18 and fixed to one end of the tubular housing 10 . The ratio (L / D) between the length (L) and the outer diameter (D) of the tubular housing 10 is preferably 4 to 8, but is not limited to this range.

[0046] The first gas generating agent 91 is charged into the booster agent containing chamber 41 formed by the tubular holder 40 . The opening portion at one end of the tubular holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com