Two-stage air-lock air locking system and air locking method thereof

An air shutoff, two-stage technology, applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, etc., can solve the problems of gas leakage, personnel poisoning, and the inability to ensure that the system is completely sealed, and achieve strong adaptability and good sealing performance , the effect of protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

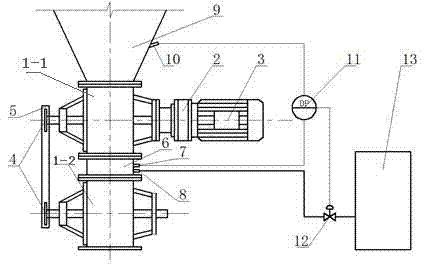

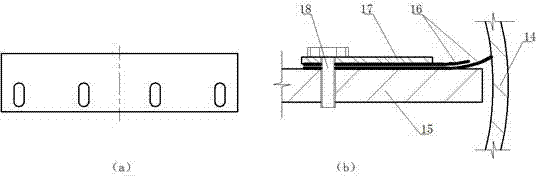

[0018] see figure 1 As shown, a two-stage air lock system includes two air locks of the same type connected in series, wherein the inlet of one air lock 1-1 is connected to the outlet of the material storage device 9, and the air lock 1-1 -1 is driven by a motor 3 equipped with a reduction box 2; the outlet of the other air shutoff device 1-2 is open to the atmosphere, the gears 4 of the two air shutoff devices are connected by a chain 5, and the air shutoff device 1-2 is connected by a chain 5 for transmission.

[0019] The pressure measuring section 6 is set between the outlet of the air lock 1-1 and the inlet of the air lock 1-2. The pressure measuring section 6 is provided with a pressure measuring port 7 and a nitrogen filling port 8; the pressure measuring port 7 is connected with the material storage equipment The pressure measuring port 10 of 9 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com