Gas generator

A generating device and gas technology, applied in the manufacture of combustible gas, granular/powdered fuel gasification, petroleum industry, etc., can solve the problems of narrow load adjustment range and low reliability, and achieve wide load adjustment range and high reliability , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

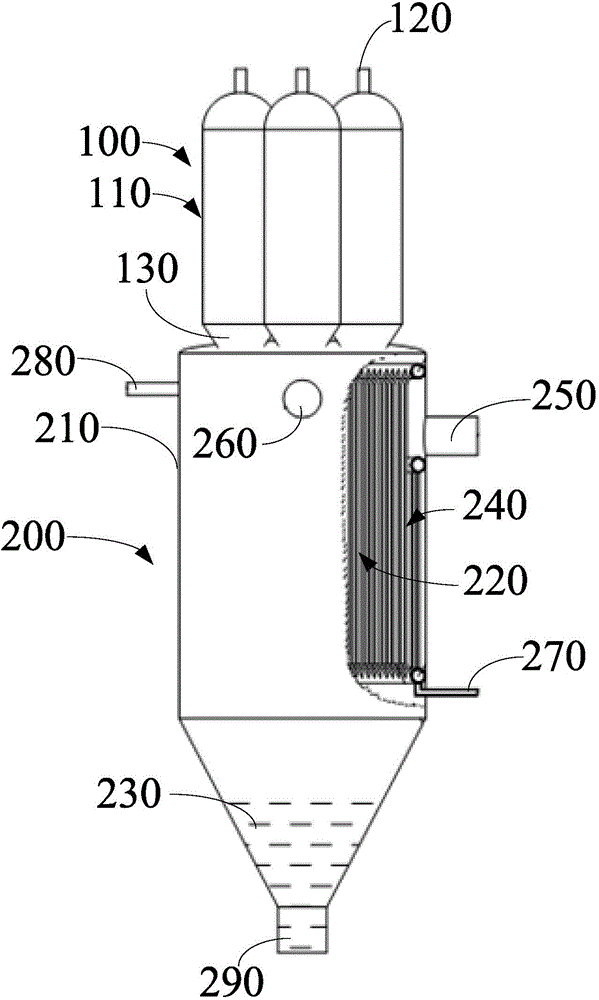

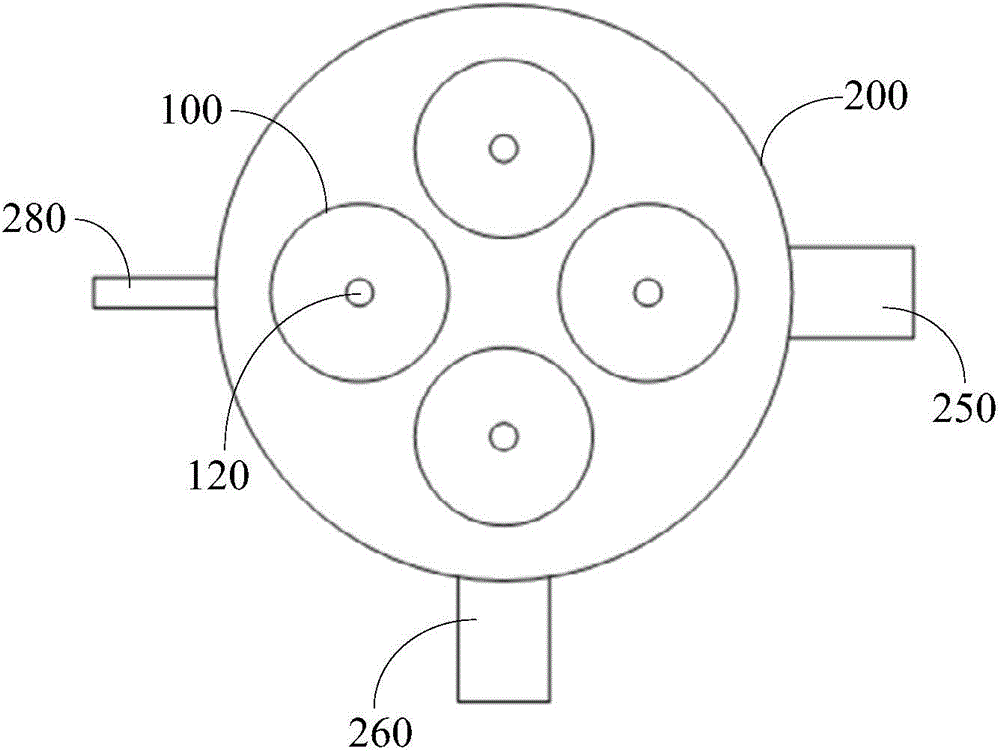

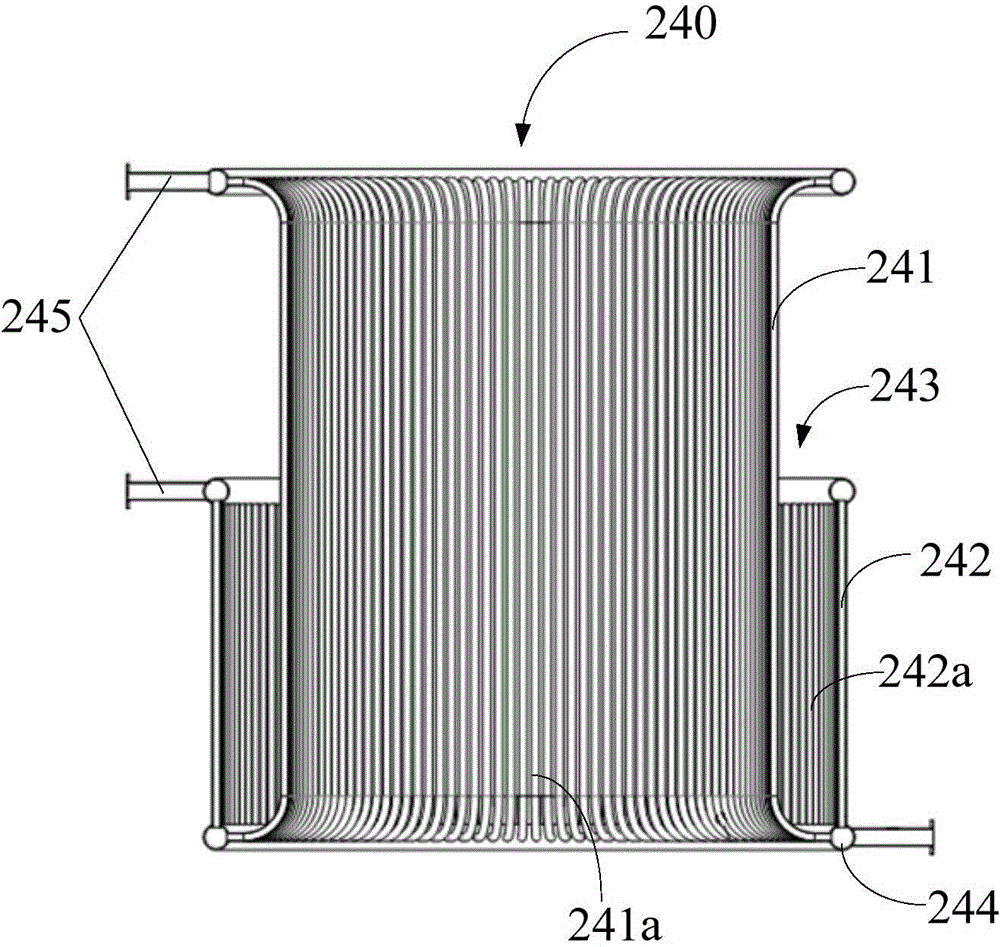

[0026] figure 1 Schematic diagram of the structure of the gas generating device provided by the embodiment of the present invention; figure 2 for figure 1 top view. combine Figure 1-2 As shown, the present invention provides a gas generating device, including a plurality of entrained-bed reaction furnaces 100 and a heat exchange boiler 200, a plurality of entrained-bed reaction furnaces 100 are fixedly arranged on the top of the heat-exchange boiler 200, each entrained-bed reaction furnace 100 is equipped with an entrained-bed reaction chamber 110, and the upper part of each entrained-bed reaction furnace 100 is provided with a pulverized coal gasification burner 120 communicated with the inside of the entrained-bed reaction chamber 110, and each entrained-bed reaction furnace 100 The reaction chambers 110 all communicate with the inside of the heat exchange boiler 200 .

[0027] When the coal gas generating device provided by the present invention is in operation, dry c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com