Ball screw pair experimental bench

A ball screw pair and ball screw technology, which is applied in the field of ball screw pair test benches, can solve problems such as the inability to accurately simulate the working conditions of high-speed and large-load ball screw pairs, difficulty in understanding product performance, and lack of detection methods. , to achieve the effects of wide load adjustable range, fast action speed and fast system response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

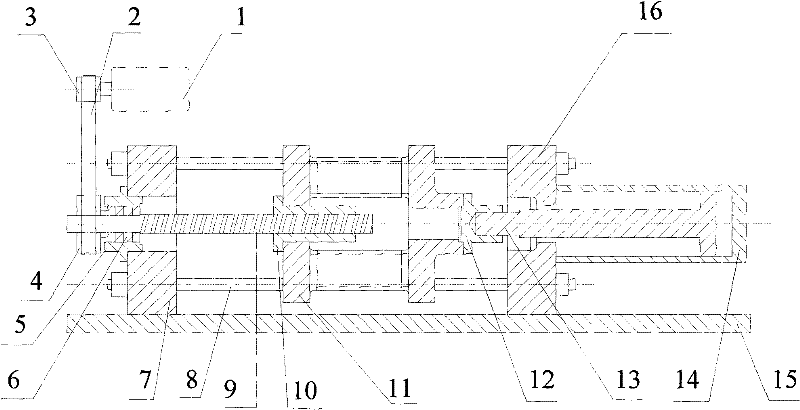

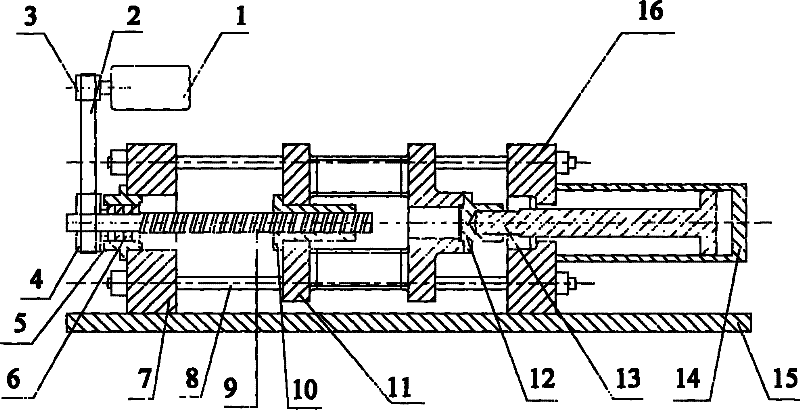

[0009] refer to figure 1 , the ball screw auxiliary test bench of the present invention includes a frame 15, a head plate 16 and a tail plate 7 are fixed on the frame 15, a connecting pull rod 8 is arranged between the head plate 16 and the tail plate 7, and a columnar Skateboard 11, one end of the columnar slideboard 11 is connected to the slideboard cover 12, the center hole of the other end of the columnar slideboard 11 is fastened with a ball nut 10, the ball screw 9 is supported on the tail plate 7 through the rolling bearing 6 and the bearing sleeve 5, the ball screw 9 One end of the ball screw 9 is screwed to the ball nut 10, the other end of the ball screw 9 is fixed with a large pulley 4, the large pulley 4 is connected with the small pulley 3 installed on the servo motor 1 through the toothed synchronous belt 2, and the head plate 16 One side of the hydraulic cylinder is fixed with a hydraulic cylinder 14, the piston rod 13 of the hydraulic cylinder passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com