Crude oil cargo hold ventilation system and offshore floating production oil storage ship comprising same

A cargo hold and crude oil technology, which is applied to ship components, ship construction, transportation and packaging, etc., can solve the problems of high production cost and unfavorable environment, and achieve the effects of saving costs, reducing exhaust gas, and protecting cargo holds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In the following, the present invention will be more clearly and completely described by way of embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

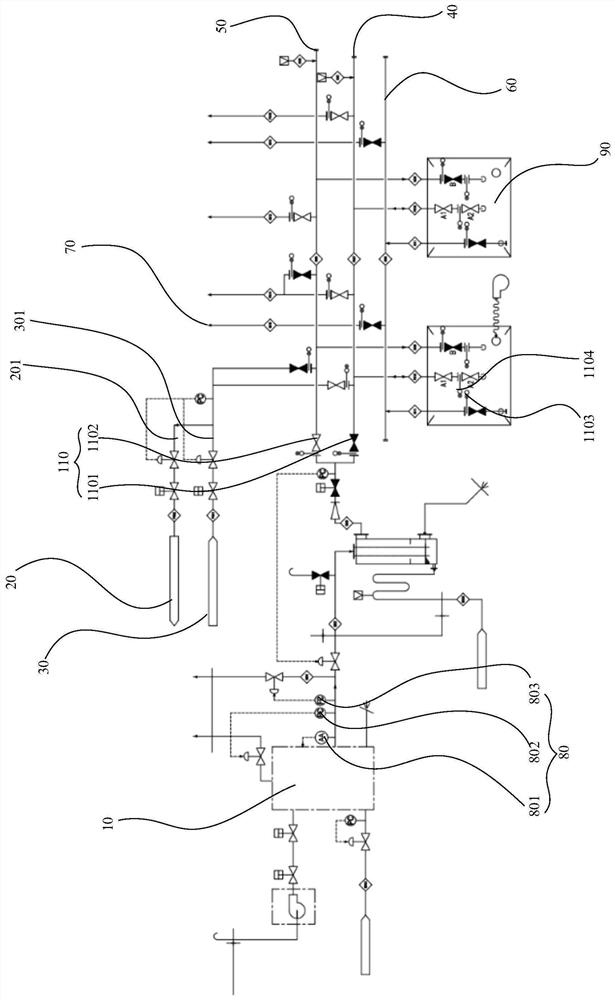

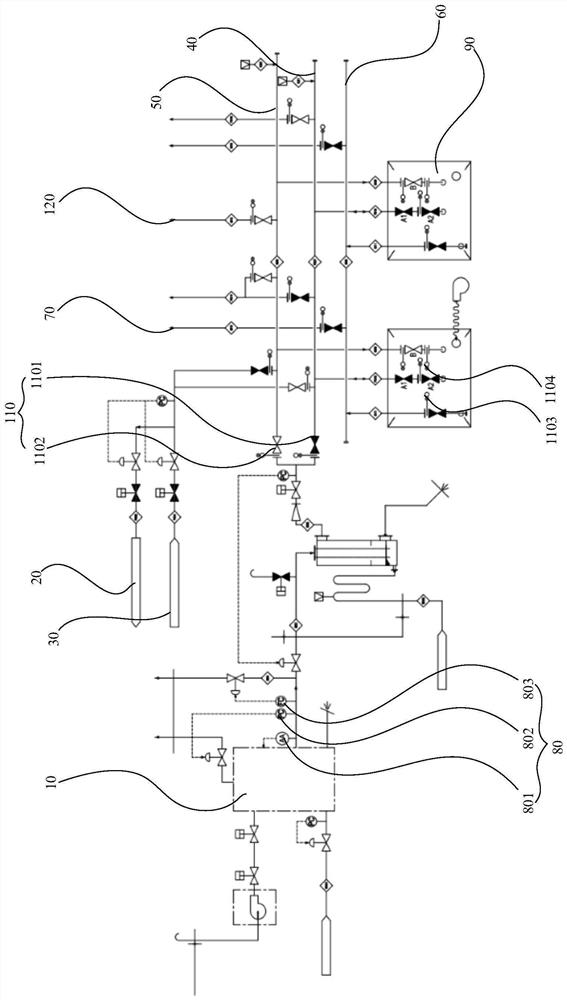

[0071] Such as figure 1 with figure 2 As shown, the present embodiment provides a crude oil cargo tank ventilation system, including an inert gas generator 10 and a hydrocarbon gas supply device 20, and the inert gas generator 10 communicates with the cargo tank 90 through a pipeline; the crude oil cargo tank ventilation system also includes a hydrocarbon gas supply device 20. gas device 20, and the hydrocarbon gas supply device 20 communicates with the cargo compartment 90 through a pipeline.

[0072] By connecting the inert gas generator 10 and the hydrocarbon gas supply device 20 with the cargo compartment 90, the cargo compartment 90 can not only replace the air in the cargo compartment 90 with the inert gas generated in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com