Explosion-proof box type vacuum microwave drier and operation method

A vacuum microwave drying, box-type technology, which is used in drying solid materials, heating to dry solid materials, and no heating to dry solid materials, etc., can solve hidden dangers in operation, and does not consider the safety of materials containing flammable and explosive substances. It can prevent explosion, simple design and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

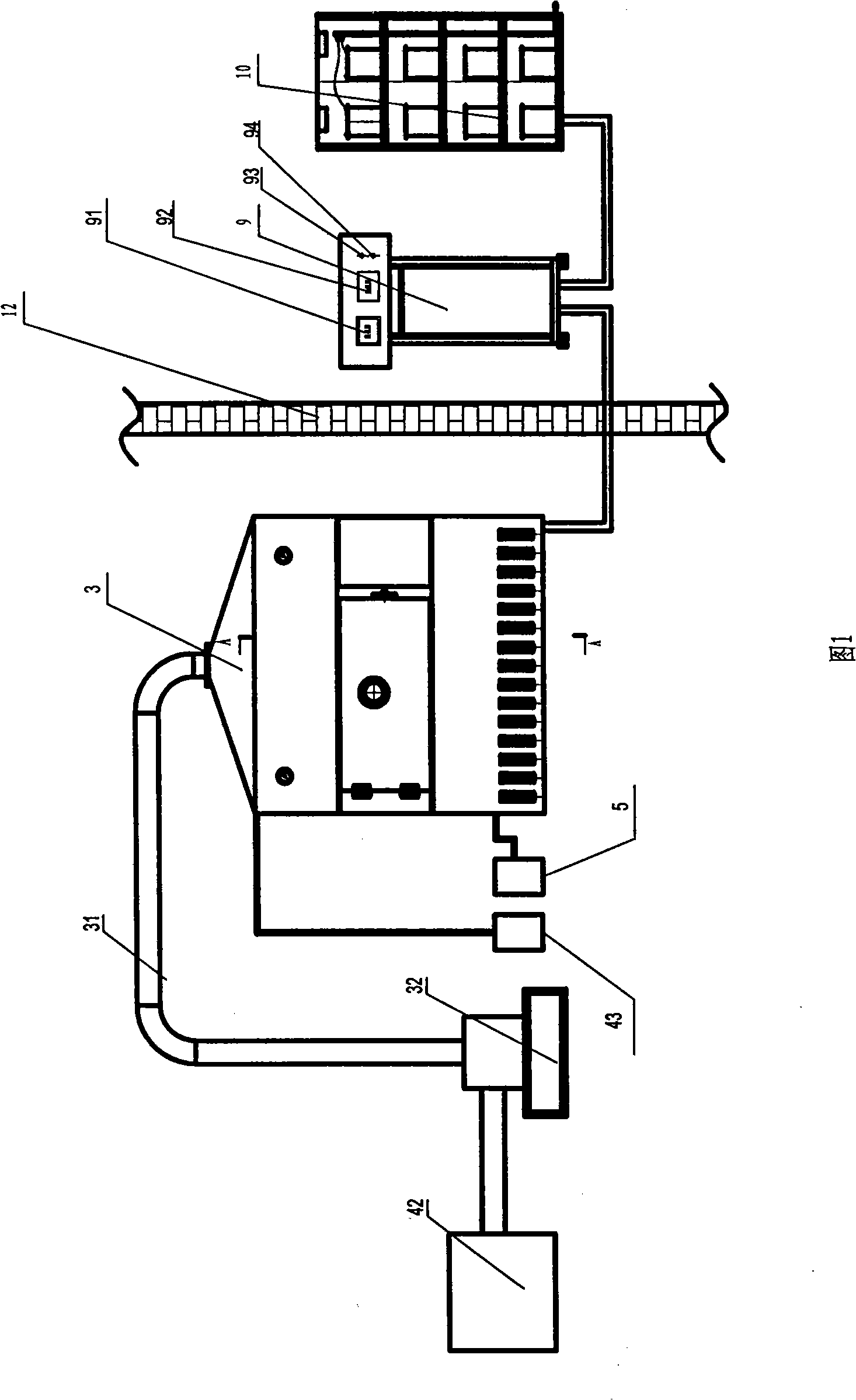

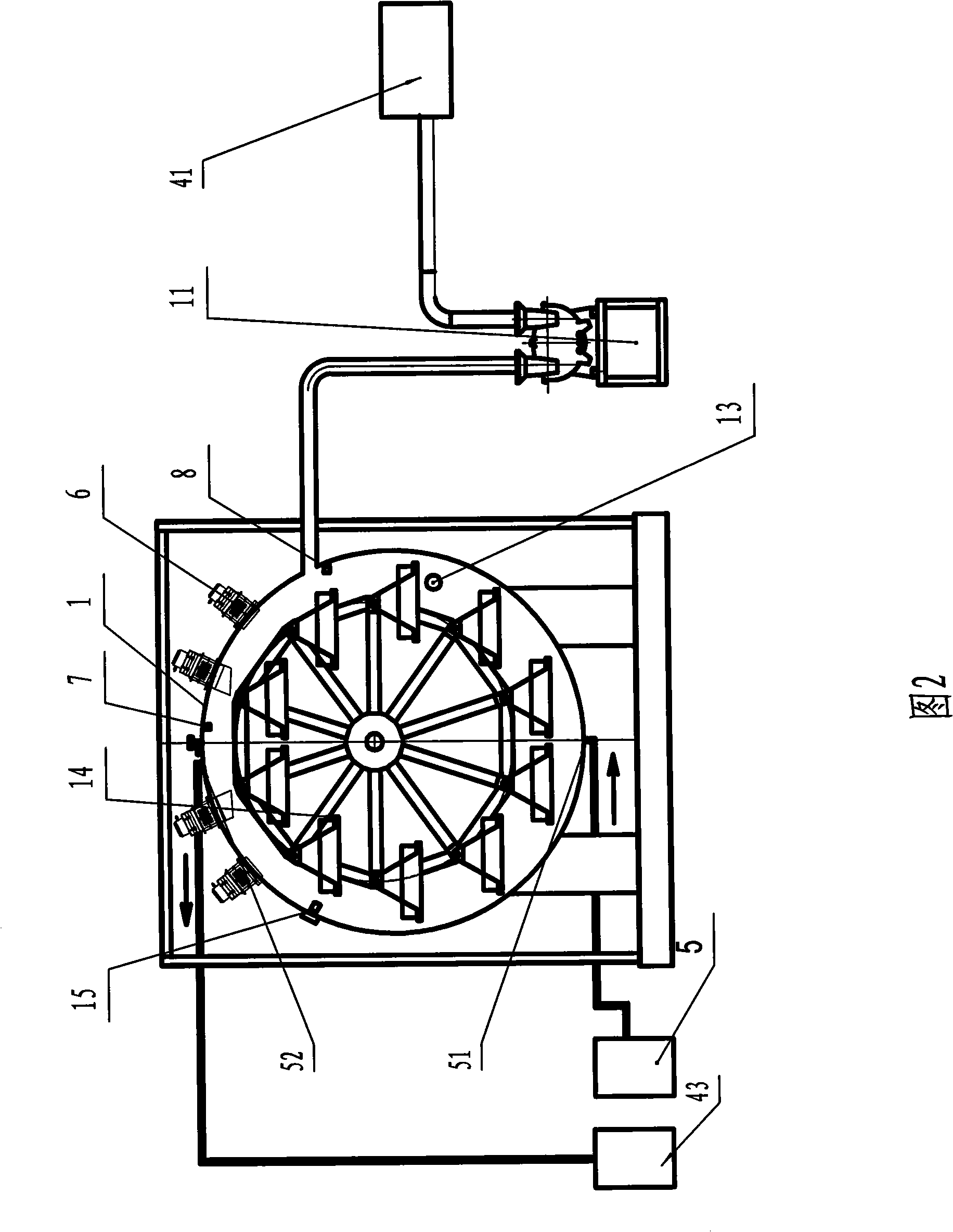

[0019] Embodiment 1, see Fig. 1, 2, described explosion-proof box-type vacuum microwave drier, comprise vacuum cavity 1 and electrical control cabinet 9, microwave generator 6 and material turning device 14 are arranged in vacuum cavity 1, The vacuum chamber 1 communicates with the vacuum device 11 through a vacuum pipe, and is characterized in that: one side of the vacuum chamber 1 is provided with an inert gas inlet 51 and an inert gas outlet 52, and one part of the vacuum chamber 1 The inert gas inlet 51 at the lower side is connected with the inert gas generator 5; the oxygen detection device 7 is arranged in the vacuum cavity 1 .

[0020] The vacuum cavity 1 is also provided with a fire detection device 8 , a pressure relief valve 13 and a pressure sensor 15 . A blowing device 3 is provided on the vacuum cavity 1 . The vacuuming device 11 is connected with the first recycling station 41 , and the blowing device 3 is connected with the second recycling station 42 . The o...

Embodiment 2

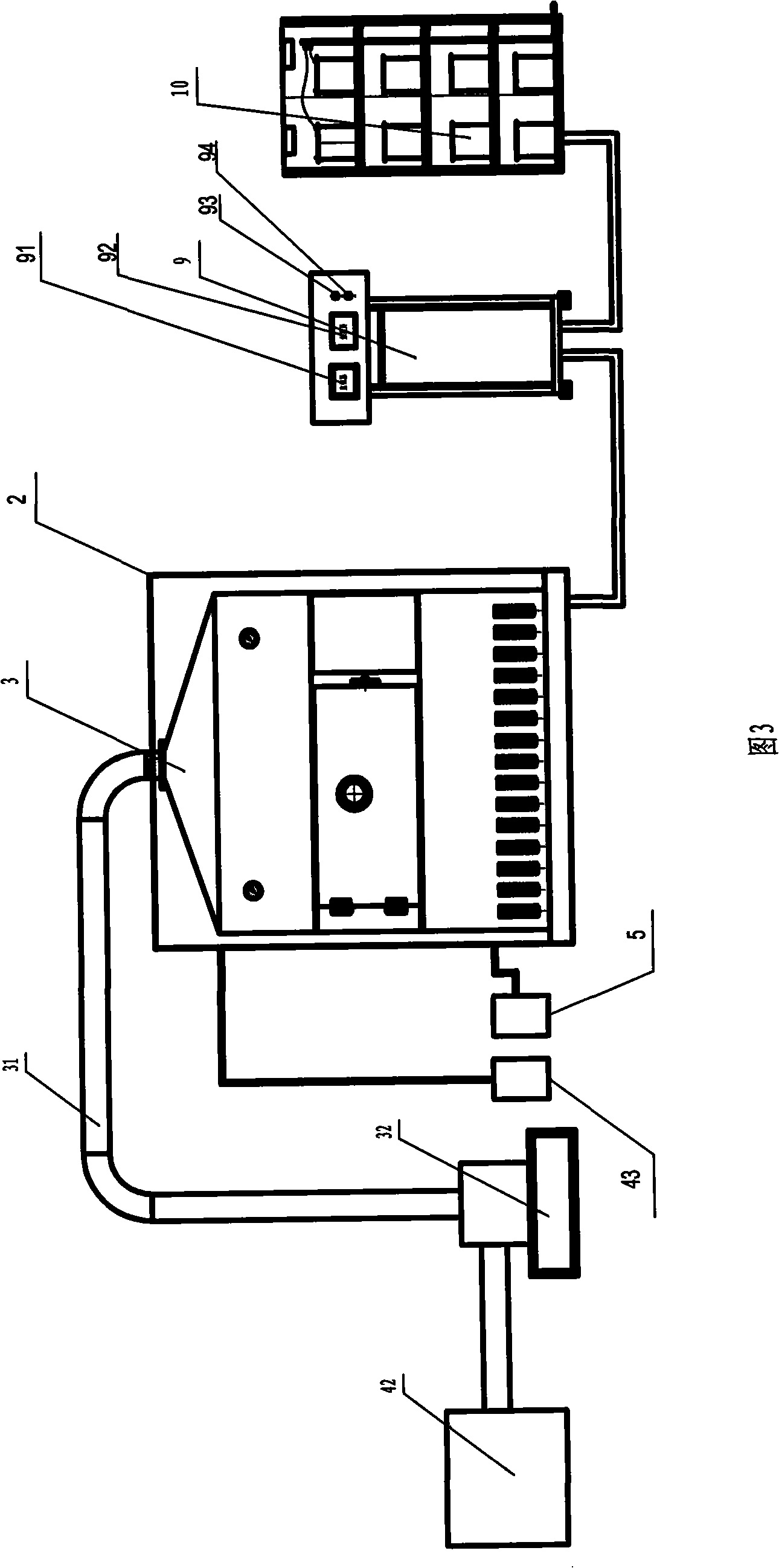

[0028] Embodiment 2, see Fig. 3, described explosion-proof box-type vacuum microwave drier, compare with embodiment 1, the exterior of vacuum chamber 1 is provided with metal protective cover 2, there is no between vacuum chamber 1 and electrical control cabinet 9 wall12. The inert gas used in the inert gas generator 5 is nitrogen. Others are the same as in Example 1.

Embodiment 3

[0029] Embodiment 3, see Fig. 4, described explosion-proof box type vacuum microwave drier, compared with embodiment 1, the inlet 51 of the inert gas on one side upper part of the vacuum chamber 1 is connected with the inert gas generator 5; The outlet 52 of the inert gas at the lower part of one side of 1 is connected with the third recovery station 43 . Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com