Environmentally-friendly efficient graphite purifying apparatus

An environmentally friendly graphite technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of shortening the service life of purification equipment, incomplete tail gas purification treatment, and low graphite purification efficiency. Novel structure, reduced energy consumption, and the effect of preventing corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

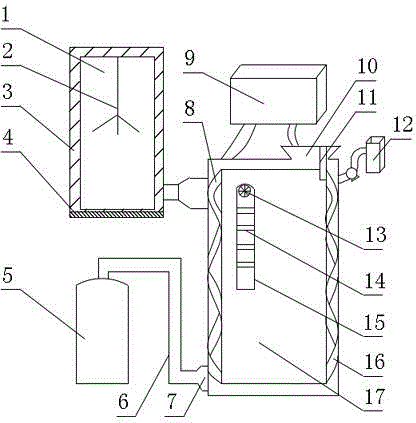

[0018] Such as figure 1 As shown, an environment-friendly graphite high-efficiency purification equipment is characterized in that the inner wall of the reactor 1 is made of rock wool material, the inner wall of the reactor 1 is provided with an insulating layer 3, and a heater 4 is installed inside the insulating layer 3, and the inner wall of the reactor 1 is A stirrer 2 is provided, and the feeding opening of the reaction kettle 1 is connected with the inlet of the purification furnace 17, and the upper end of the purification furnace 17 is provided with an acid-adding hole 10, and an acid liquid flowmeter 11 is also arranged on the acid-adding hole 10, and the outlet of the purification furnace 17 Tail gas outlet 7 is set at the lower end, and tail gas outlet 7 is connected to acid mist absorption tower 5 through tail gas conveying pipe 6, and water outlet pipe 8 and water inlet pipe 16 are arranged between the lining and outer wall of purification furnace 17, water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com