High-moisture brown coal pulverizing and drying apparatus and method thereof

A drying device and lignite technology, applied in the direction of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of inadaptability to lignite grinding and drying, and inertization of coal powder preparation system, and achieve a wide range of coal types , small running resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

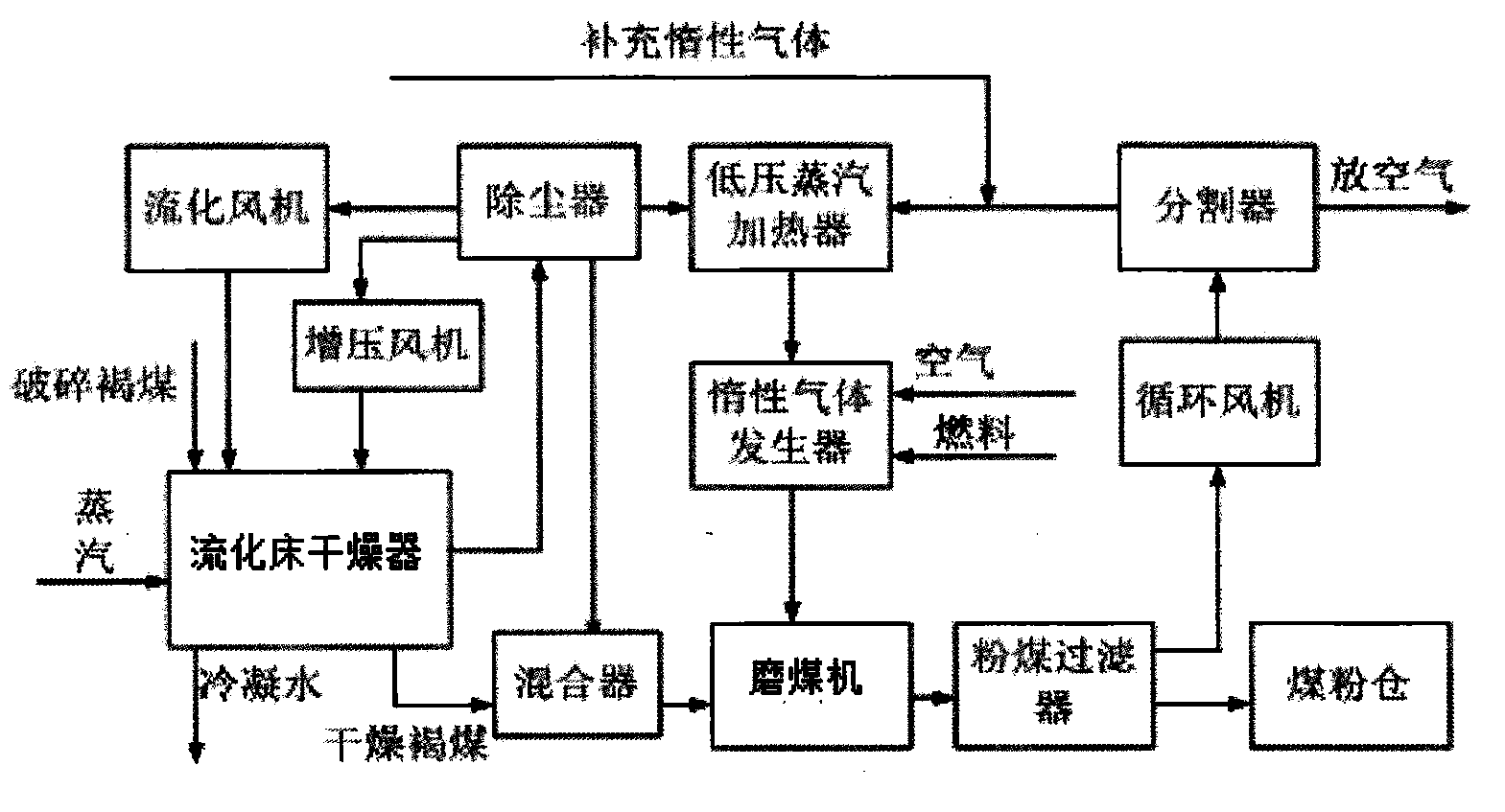

[0027] Such as figure 1 Shown is a schematic diagram of a lignite coal grinding and drying device, the lignite coal grinding and drying device consists of a fluidized bed dryer, a mixer, a coal mill, a pulverized coal filter, a pulverized coal bin, a circulating fan, a divider, Composed of low-pressure steam heating gas, inert gas generator, booster fan, dust collector and fluidization fan. The secondary steam and lignite mixture outlet of the fluidized bed dryer is connected to the inlet of the dust collector, the lignite outlet of the dust collector is connected to the inlet of the mixer, and the steam outlet of the dust collector is connected to the steam inlet of the low pressure steam heater, the inlet of the fluidization fan and The inlet of the booster fan, the outlet of the fluidization fan is connected to the fluidized gas inlet of the fluidized bed dryer, the outlet of the booster fan is connected to the steam coil of the fluidized bed dryer, and the dry lignite outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com