Gas generator

A technology for gas generators and firearms, which is applied to gas generating devices, chemical instruments and methods, and vehicle safety arrangements, and can solve problems such as inability to maintain pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0065] The present invention can be applied as long as the cup member and the igniter collar of the igniter can be assembled by press fitting.

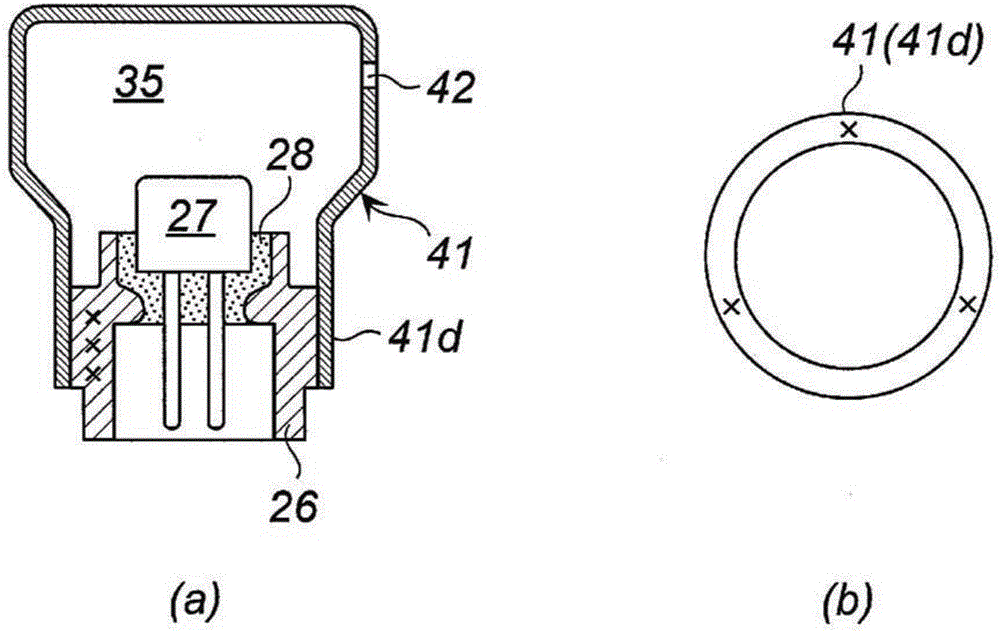

[0066] For example, the present invention can be applied to: with JP-A No.2010-892 figure 1 The gas generator showing the combination of the first cup member 32 and the first igniter collar 22, the second cup member 41 and the second igniter collar 26 has JP-A No. 2010-70073 figure 1 The combination of the combustion chamber cup 30 and the collar 41 shown, the combination of the cup 132 and the collar 122 of FIG. 3 of JP-A No. 2007-118788, the combination of the cup 141 and the collar 126 are gas generators, and the like.

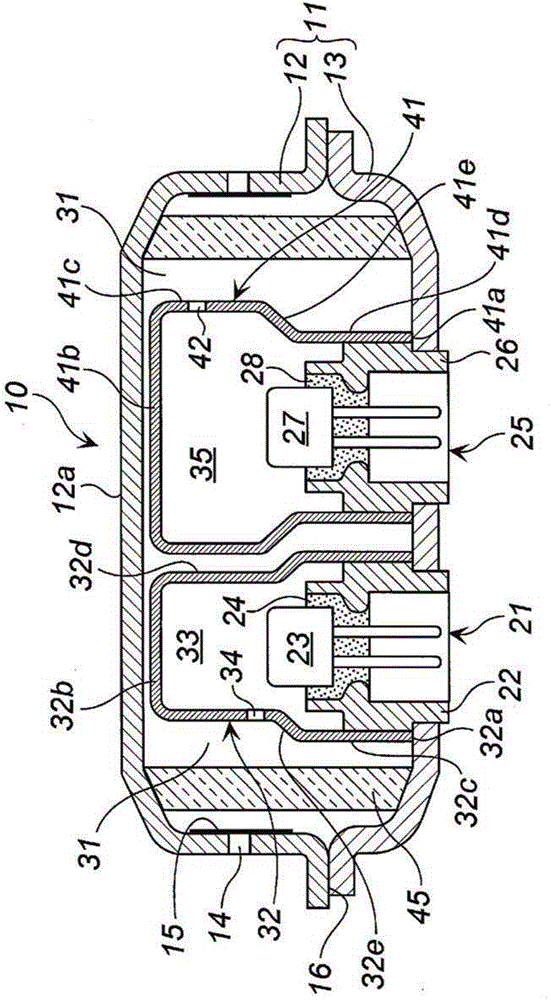

[0067] Use the following figure 1 (and of JP-A No.2010-892 figure 1 same) for explanation.

[0068] For the gas generator 10 , an outer casing is formed by a case 11 in which a diffuser case 12 and a closure case 13 are welded at joint portions 16 .

[0069] A plurality of gas discharge ports 14 are provided on...

Embodiment 1 and comparative example 1

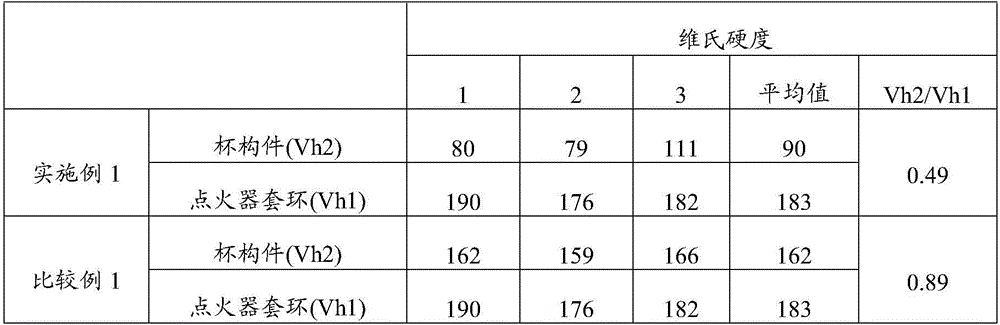

[0107] The method of measuring the average Vickers hardness of the first igniter collar 22 and the second igniter collar 26 is as follows. In addition, these measurement methods and measurement values are the same, and are demonstrated below as the measurement method of the 2nd igniter collar 26.

[0108] Both the first igniter collar 22 and the second igniter collar 26 were formed of carbon steel (C content: 0.15% by mass), and both Example 1 and Comparative Example 1 were not annealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com