Carbon crystal heating wall heating product and production process thereof

A carbon crystal and production process technology, which is used in household heating, heating methods, electric heating systems, etc., can solve the problems of small application area of quartz tube electric heating, slow heating of houses, and difficulty in handling, so as to avoid defective products from entering the market. , The effect of ensuring printing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

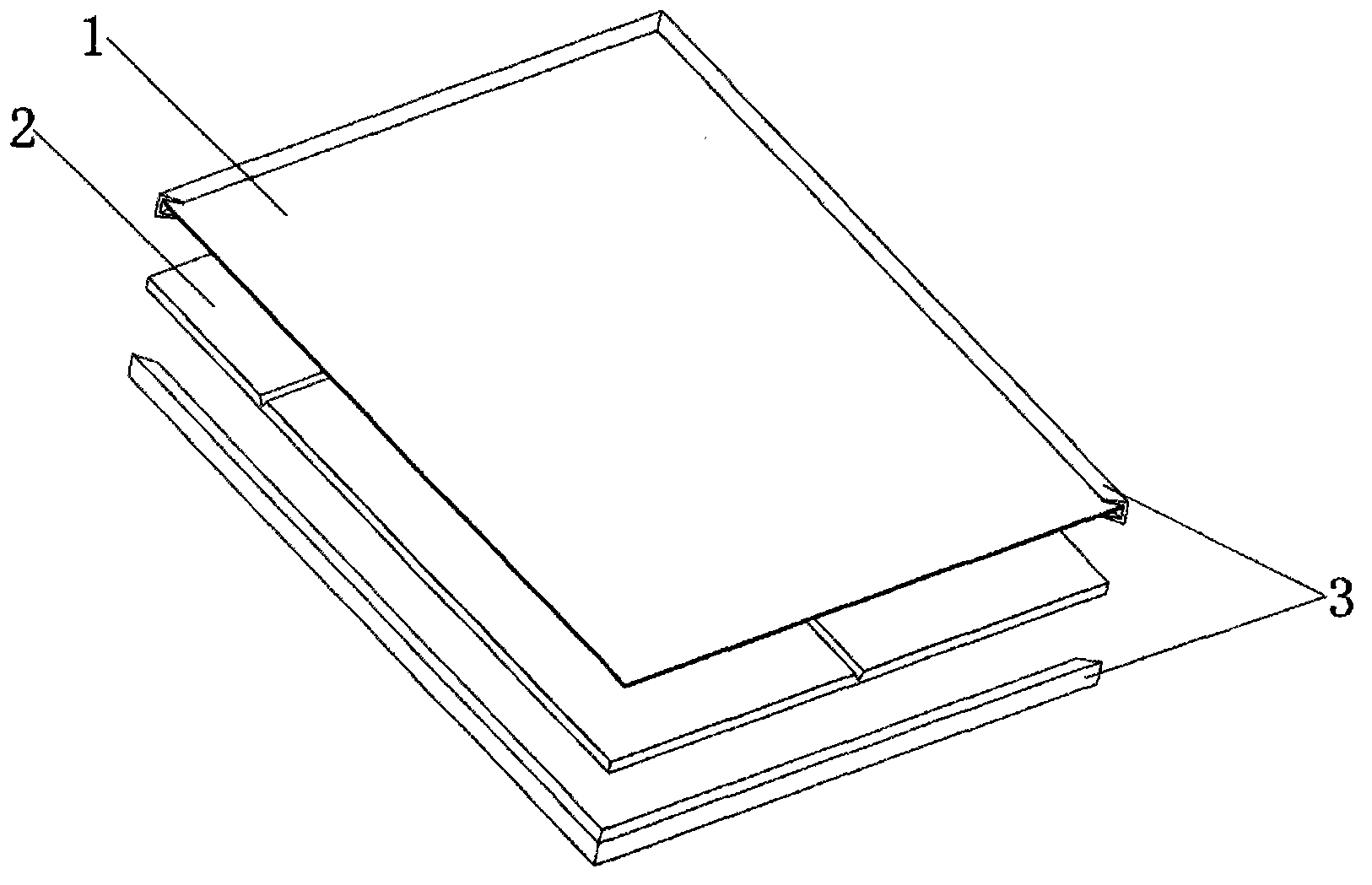

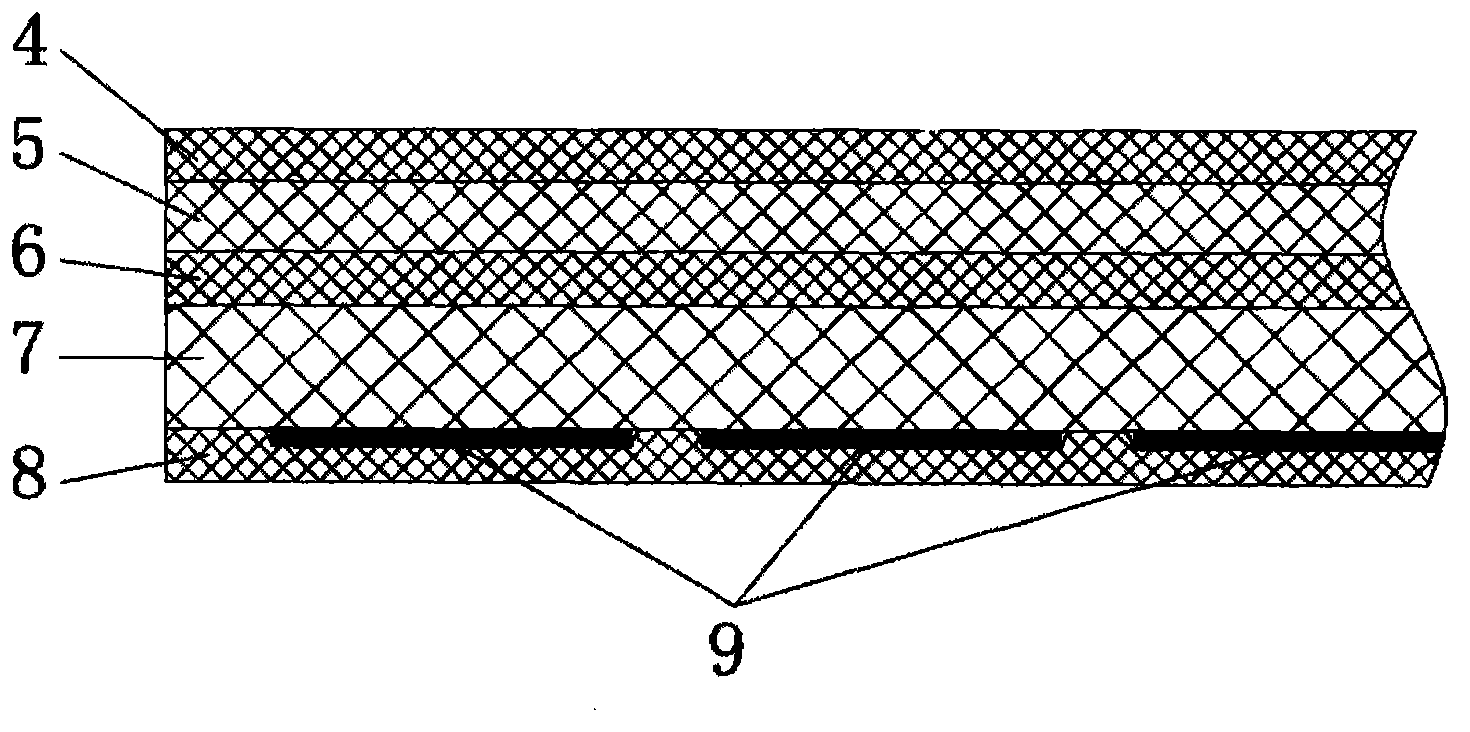

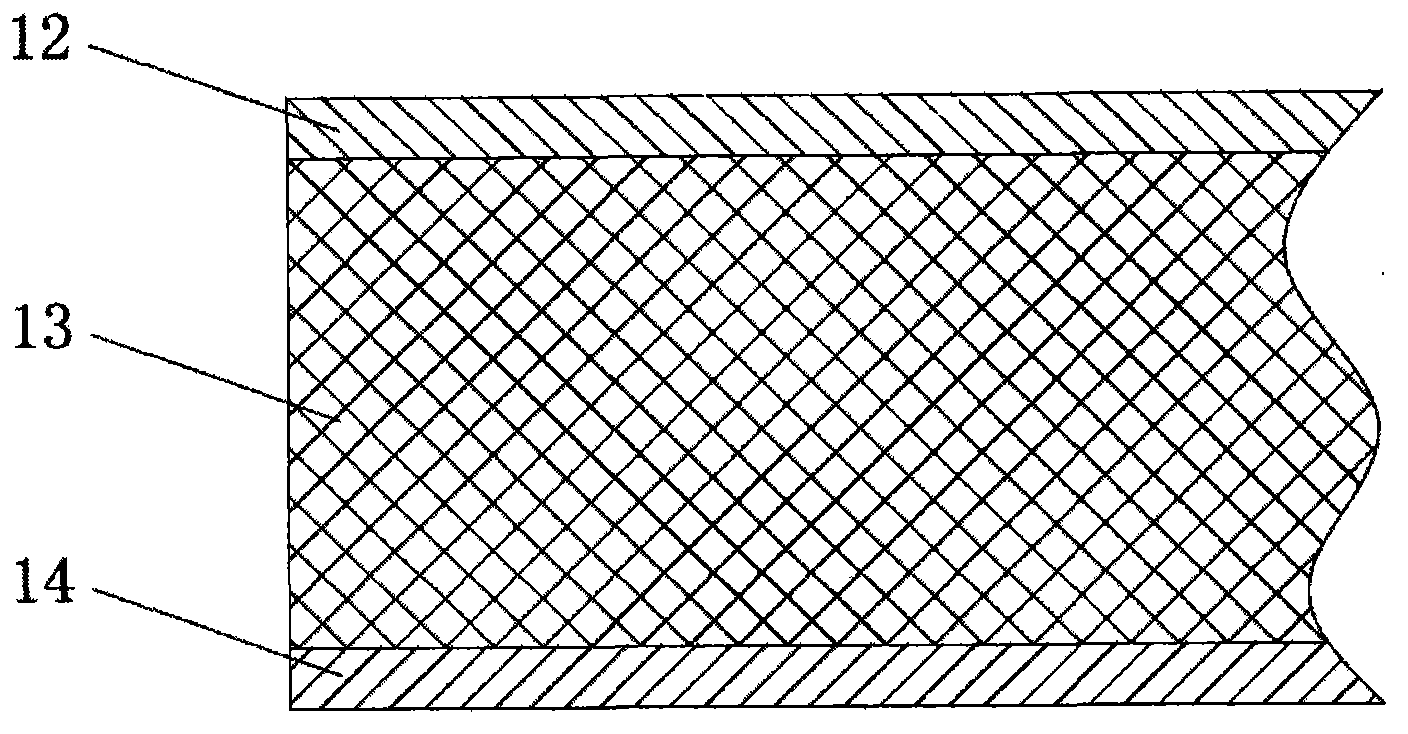

[0042] Such as figure 1 , 2 , 3, and 4, a carbon crystal heating wall heating product includes a carbon crystal heating plate (1), a reflective heat shield (2), a fixed frame (3), and the carbon crystal heating plate (1) includes a surface Protective layer (4), decorative layer (5), connecting layer (6), heating layer (7), insulating layer (8), carbon crystal heating film (9), first conductive copper strip (10), second The conductive copper strip (11), the first conductive copper strip (10) is provided with the first contact (15), the second conductive copper strip (11) is provided with the second contact (16), and the reflective heat shield ( 2) including an upper reflection layer (12), a heat insulation layer (13), and a lower reflection layer (14); the first conductive copper strip (10) and the second conductive copper strip (11) are respectively fixed on the same heating layer (7) At both ends of the side, the carbon crystal heating film is printed on the side of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com