Production method for preparing ammonium sulfate by alkylating waste acid

A technology of alkylation waste acid and production method, which is applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., can solve problems such as yellowing of ammonium sulfate crystals, difficult recovery of polymerized oil, and difficult disposal of waste sulfuric acid, and achieve saving The effect of reducing time cost, reducing production cost, and avoiding waste of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

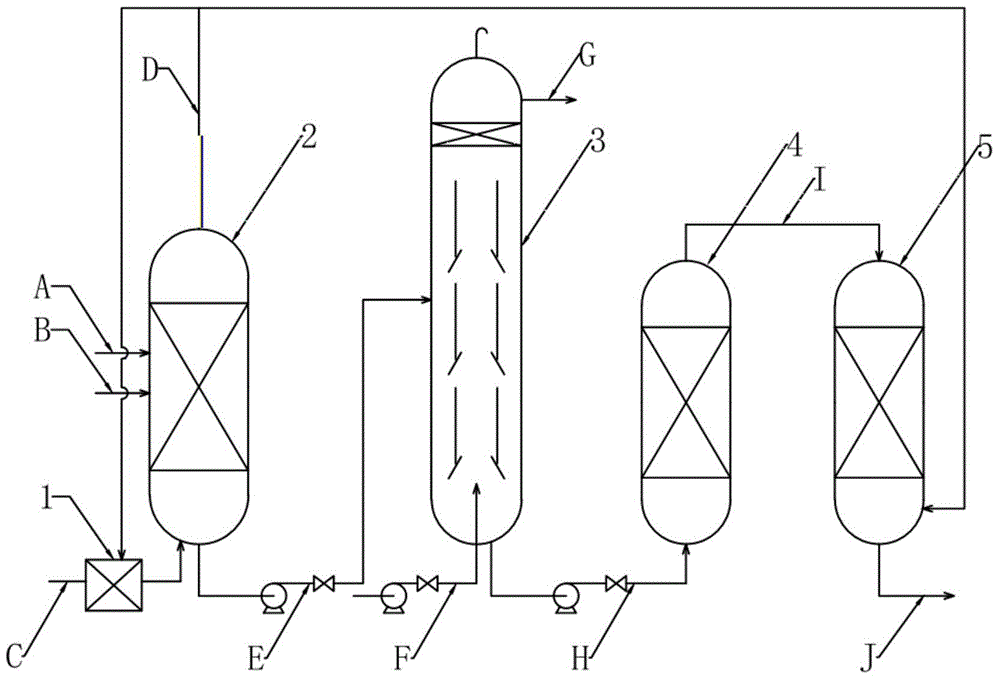

[0024] Describe in detail below in conjunction with accompanying drawing:

[0025] Such as figure 1 Shown, the production technology that alkylation waste acid of the present invention prepares ammonium sulfate is to be with waste concentrated sulfuric acid, liquefied ammonia as raw material production ammonium sulfate. The raw material water (A) is input into the reactor (2) through the water delivery pipeline, the liquid ammonia (C) is vaporized into ammonia gas by the vaporizer (1), and is passed into the reactor through the gas distributor to dissolve to generate ammonia water, and the waste acid (B) It is transported to the reactor through the distributor and neutralized with ammonia water. The hot steam (D) generated by the reaction is transported to the raw material liquid ammonia vaporizer (1) and the crystallizer (5) through the steam pipeline, and is used in the process of liquid ammonia vaporization and ammonium sulfate solution crystallization. The ammonium sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com