Organic silicon coating glue and preparation method thereof

A technology of coating glue and silicone, which is applied in the field of new silicone materials, can solve problems such as easy breakage or cracking, prolonged surface dry time, and affecting processing and use, so as to improve machinability, excellent aging resistance, and prolong use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

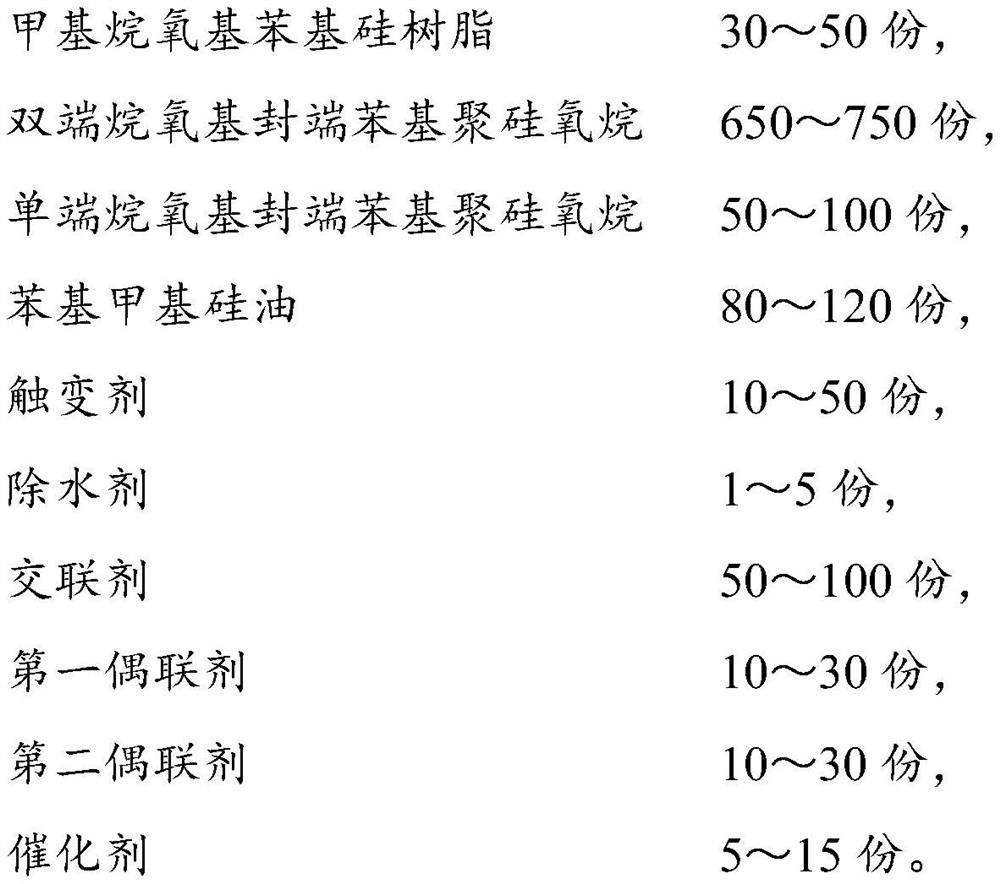

Method used

Image

Examples

Embodiment 1

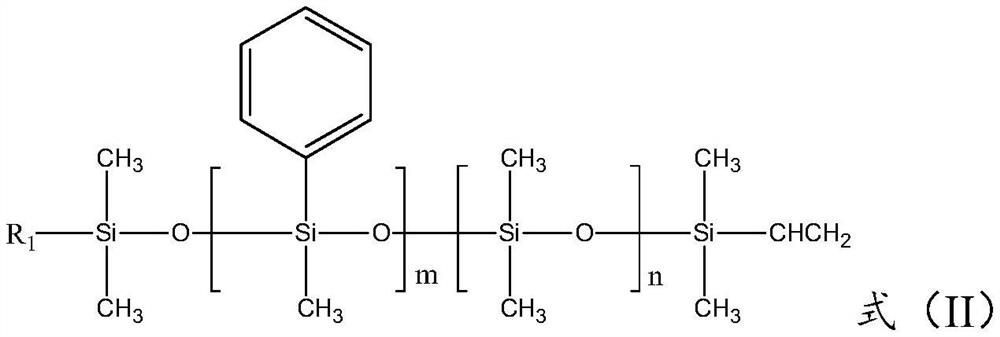

[0065] Synthesis of double-terminated alkoxy-terminated phenylpolysiloxane:

[0066] 1000g of double-ended vinylphenyl polydimethylsiloxane (R1 is vinyl, vinyl content 1.7wt%) having a viscosity of 50mPa·s with a structural formula such as (II) was stirred under vacuum at 150 degrees Celsius for 2h, and continued Stir and evacuate and cool down to 30°C; nitrogen (anhydrous) to break the vacuum and protect, add 1.1g chloroplatinic acid catalyst solution (weight ratio, anhydrous chloroplatinic acid:isopropanol=1:100), continue mixing for 30min; nitrogen Under protection, heat up to 100°C, add 110g of hydrogen-containing alkoxysilane, after the slow addition, react at 100°C for 2 hours; after the time is up, 120°C vacuum stir for 2 hours, remove low-boiling and unreacted raw materials; nitrogen protection to cool down At 25°C, add graphite powder to absorb and remove chloroplatinic acid; after filtration, obtain the desired double-terminated alkoxy-terminated phenyl polysiloxane-...

Embodiment 2

[0072] Synthesis of double-terminated alkoxy-terminated phenylpolysiloxane:

[0073] 1000g of double-ended vinylphenyl polydimethylsiloxane (R1 is vinyl, vinyl content 0.32wt%) with a viscosity of 1000mPa·s structural formula such as (II) was vacuum-stirred at 150 degrees Celsius for 2h, and continued Stir and evacuate and cool down to 30°C; nitrogen (anhydrous) to break the vacuum and protect, add 1.7g chloroplatinic acid catalyst solution (weight ratio, anhydrous chloroplatinic acid:isopropanol=1:100), continue mixing for 30min; nitrogen Under protection, raise the temperature to 100°C, add 22g of hydrogen-containing alkoxysilane, after the slow addition, react at 100°C for 2 hours; after the time is up, stir at 120°C for 2 hours in vacuum to remove low-boiling and unreacted raw materials; nitrogen protection to cool down At 25°C, add graphite powder to absorb and remove chloroplatinic acid; after filtration, obtain the desired double-terminated alkoxy-terminated phenyl poly...

Embodiment 3

[0079] Synthesis of double-terminated alkoxy-terminated phenylpolysiloxane:

[0080] Stir 1000g of double-ended vinylphenyl polydimethylsiloxane (R1 is vinyl, vinyl content 0.16wt%) with a viscosity of 5000mPa·s under vacuum for 2h at 150°C, continue Stir and evacuate and cool down to 30°C; nitrogen (anhydrous) to break the vacuum and protect, add 2.1g chloroplatinic acid catalyst solution (weight ratio, anhydrous chloroplatinic acid:isopropanol=1:100), continue mixing for 30min; nitrogen Under protection, raise the temperature to 100°C, add 12g of hydrogen-containing alkoxysilane, after the slow addition, react at 100°C for 2 hours; after the time is up, stir at 120°C for 2 hours under vacuum to remove low-boiling and unreacted raw materials; nitrogen protection to cool down At 25°C, add graphite powder to absorb and remove chloroplatinic acid; after filtration, the desired double-ended alkoxy-terminated phenyl polysiloxane-3 is obtained;

[0081] Synthesis of single-ended a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com