One-component dealcoholized room temperature vulcanizing organopolysiloxane composition

An organopolysiloxane, room temperature vulcanization technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of difficult processing and poor storage stability, and achieve easy operation, easy processing, and convenience The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

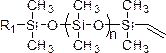

[0027] Example 1 Double-ended alkoxy-terminated polydimethylsiloxane

[0028] Under inert gas conditions, add 100 g of double-ended vinyl polydimethylsiloxane with a viscosity of 1000 mPa.s (vinyl content is 0.32%) and 0.6 g of a commercially available platinum catalyst with a Pt content of 3000 ppm to the reactor Pt-3000, stir evenly, and keep warm at 40°C for 1 hour, then slowly add 1.95g of triethoxysilane dropwise to it, after the dropwise addition, keep warm at 120°C for 3h to get colorless and transparent Two-terminal alkoxy-terminated polydimethylsiloxane A with the same two-terminal functional groups.

Embodiment 2

[0029] Example 2 Two-terminal alkoxy-terminated polydimethylsiloxane

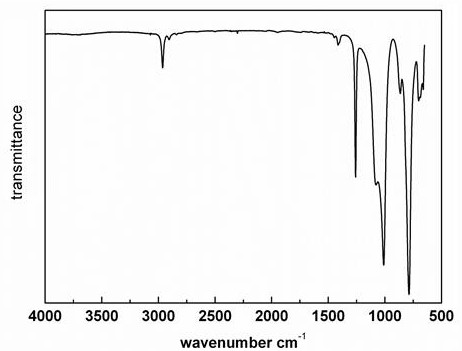

[0030] Under inert gas conditions, add 200 g of double-ended vinyl polydimethylsiloxane with a viscosity of 100,000 mPa.s (vinyl content of 0.06%) and 0.01 g of commercially available carboxy with a Pt content of 20% to the reactor. Stirr catalyst, stirred evenly, and kept at 50°C for 0.5 h, then slowly added dropwise a mixture of 0.56g of hydrogen-containing alkoxysilane I and 0.53g of hydrogen-containing alkoxysilane II, after the dropwise addition, Insulated and reacted at 80°C for 6 hours, a colorless and transparent two-terminal alkoxy-terminated polydimethylsiloxane B with different functional groups at both ends was obtained. The infrared spectrum is shown in figure 1 , IR results show that the alkoxy-terminated polydimethylsiloxane prepared by this method has no Si-OH.

Embodiment 3

[0031] Example 3 Single-ended alkoxy-terminated polydimethylsiloxane

[0032] Under inert gas conditions, add 150 g of single-ended vinyl polydimethylsiloxane with a viscosity of 20,000 mPa.s (vinyl content is 0.05%) and 0.15 g of a commercially available platinum catalyst with a Pt content of 5,000 ppm to the reactor Pt-5000, stirred evenly, and reacted at 60°C for 0.5 h, then slowly added 0.39g of trimethoxysilane dropwise to it, after the dropwise addition, kept at 100°C for 5h to obtain trifunctional mono Alkoxy-terminated polydimethylsiloxane C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com