Preparation method of magnetic porous carbon/ ferric oxide nano composite material for oil-water separation

An iron oxide nanometer, oil-water separation technology, applied in chemical instruments and methods, alkali metal compounds, immiscible liquid separation, etc. The effects of operability and development prospects, low production cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation, namely porous carbon / Fe 3 o 4 powder.

[0027] The preparation method of the above-mentioned magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation specifically includes the following steps:

[0028] Firstly, Fe-MIL-101 metal-organic framework material with porous structure was prepared by hydrothermal method;

[0029] Then, the obtained Fe-MIL-101 metal-organic framework material with a porous structure was controlled at a heating rate of 5 °C / min, under H 2 :N 2 The flow rate is 4%: under the condition of 96%, the temperature is raised to 600°C, and calcined for 6h, the porous carbon / Fe 3 o 4 Magnetic powder, that is, magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation.

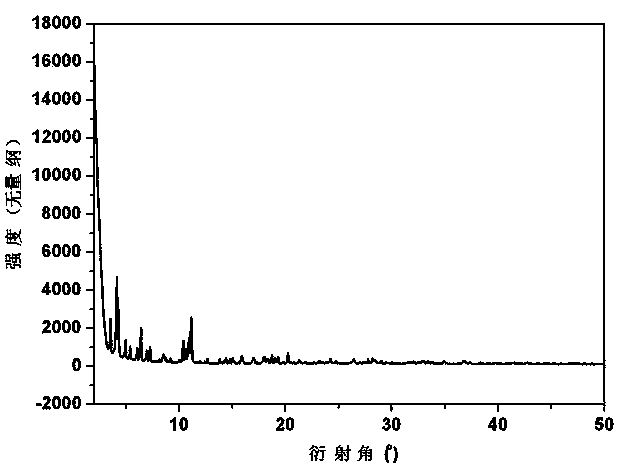

[0030] The precursor Fe-MIL-101 used above was scanned by a Rigaku D / max 2000 / PC X-ray diffractometer, and the obtained ...

Embodiment 2

[0035] A magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation, namely porous carbon / γ-Fe 2 o 3 powder.

[0036]The preparation method of the above-mentioned magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation specifically includes the following steps:

[0037] First, Fe-MIL-100 metal-organic framework materials with porous structure were prepared by hydrothermal method;

[0038] Then, control the heating rate of the obtained Fe-MIL-100 metal-organic framework material with a porous structure at 2.5°C / min, and calcinate it at 500°C for 8 hours in a vacuum state to obtain black porous carbon / γ-Fe 2 o 3 Powder, that is, magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation.

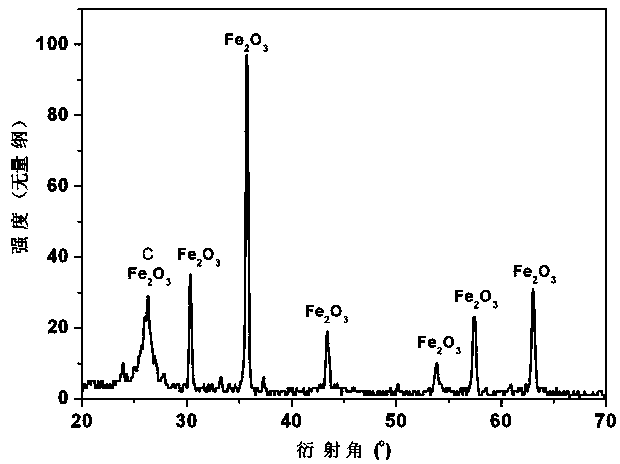

[0039] The black porous carbon / γ-Fe obtained above 2 o 3 The magnetic powder, that is, the magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation...

Embodiment 3

[0044] A magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation, namely porous carbon / Fe 3 o 4 powder.

[0045] The preparation method of the above-mentioned magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation specifically includes the following steps:

[0046] First, Fe-MIL-100 metal-organic framework materials with porous structure were prepared by hydrothermal method;

[0047] Then, the obtained Fe-MIL-100 metal-organic framework material with a porous structure was controlled at a heating rate of 2°C / min. 2 :N 2 The flow rate is 4%: under the condition of 96%, the temperature is raised to 500°C, and calcined for 4 hours, the porous carbon / Fe 3 o 4 Magnetic powder, that is, magnetic porous carbon / iron oxide nanocomposite adsorption material for oil-water separation.

[0048] The porous carbon / Fe obtained above 3 o 4 Magnetic powder, tested by BET with Autosorb-1 of American Kangta Company...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com