Modified photo-hardening resin composition for high-wear-resistance/high-toughness/high-hardness nanometer materials

A technology of light-hardening resin and nanomaterials, which is applied in the treatment of dyed low-molecular-weight organic compounds, fibrous fillers, etc., to achieve the effect of saving electricity cost and material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

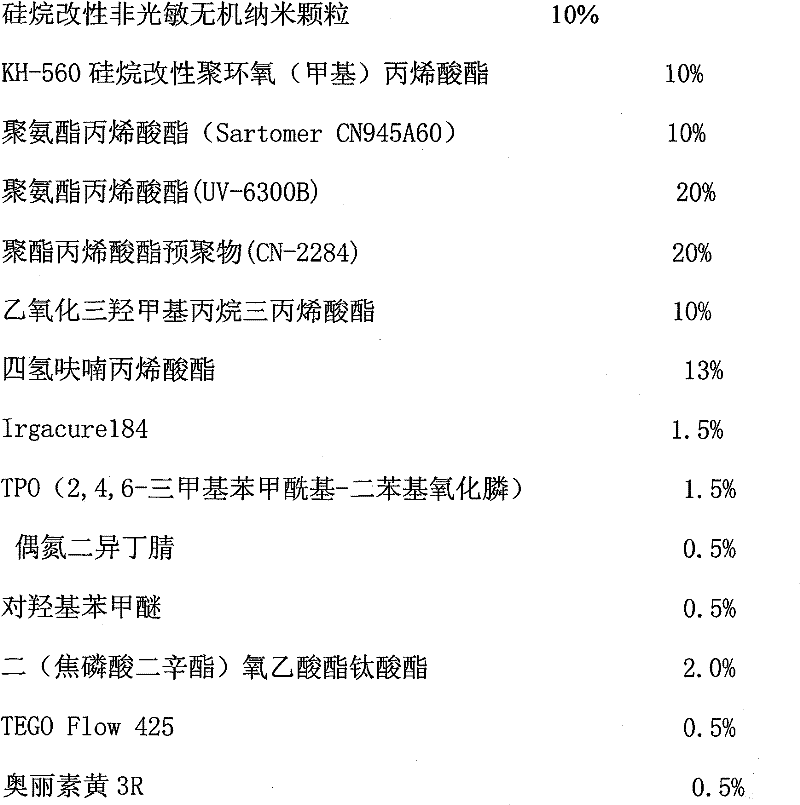

[0052] In the stainless steel bucket, first add prepolymers such as silane-modified polyepoxy (meth)acrylate prepolymer and urethane acrylate, then add the mixed reactive diluent, stir to dissolve, and then add the self-made silane-modified non- Photosensitive inorganic nanoparticle material, then continue to add UV photoinitiator, thermal initiator and a small amount of polymerization inhibitor, coupling agent, leveling agent, defoamer and complex metal dye, etc., and stir evenly with a high-speed mixer to obtain three System hardening resin composition, ready to use.

[0053] Silane-modified non-photosensitive inorganic nanoparticles 0.1-60% (example 1%, 30%, 60%)

[0054] Silane-modified polyepoxy (meth)acrylate prepolymer 0-50% (example 1%, 20%, 50%)

[0055] Resin prepolymer mixture 5-50% (eg 5%, 30%, 50%)

[0056] Mixed reactive monomers 10-80% (eg 15%, 50%, 80%)

[0057] Photoinitiator 0.1~10% (Example 1%, 5%, 10%)

[0058] Thermal initiator 0.1~10% (Example 1%, 5%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com