Photocurable resin composition

A technology of photocurable resin and composition, which is applied in the field of photocurable resin composition, can solve the problems of long time consumption, cost becoming a problem, and limitation of fine pattern formation, etc., and achieve investment cost saving, excellent coating property, fast The effect of light curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1、2

[0048] According to the composition of the following Table 1, each component was mixed, and it mixed uniformly at normal temperature for 6 hours or more, and the resin composition (unit: weight part) was manufactured.

[0049] At this time, the components used are as follows.

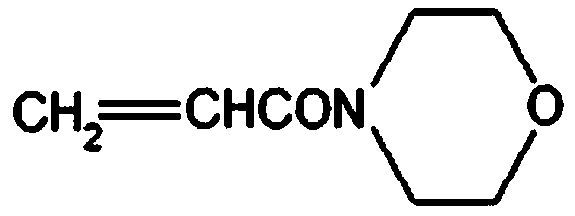

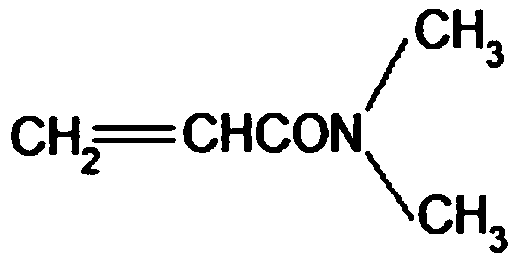

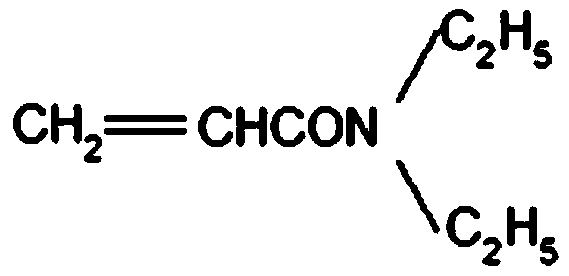

[0050] Acrylamide monomer: acryloyl morpholine (ACMO, Acryloyl morpholine, manufactured by Japan Kyojin Company) of chemical formula 1, dimethylacrylamide (DMAA, N, N-Dimethyl acrylamide, manufactured by Japanese Kyojin Company) of chemical formula 2, chemical formula 3 Diethylacrylamide (N,N-diethyl acrylamide) and chemical formula 4 dimethylaminoethyl acrylate (N,N-dimethylamino ethylacrylate);

[0051] Acrylic copolymer resin: (polyester acrylate (PS420, tetrafunctional polyester acrylate (Tetrafunctional Polyester acrylate), Korea Miwon Specialty Chemical Company);

[0052] Vinyl monomer: (glycidyl methacrylate (GMA, Glycidyl metaacrylate, Sigma-Aldrich);

[0053] Cross-linking monomers: pentaeryt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com