Application and preparation method of photocurable polyimide ink for 3D printing

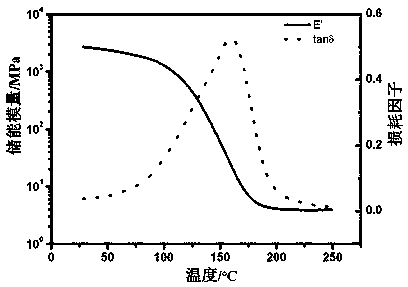

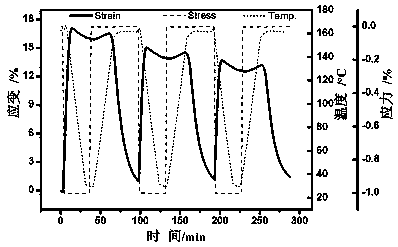

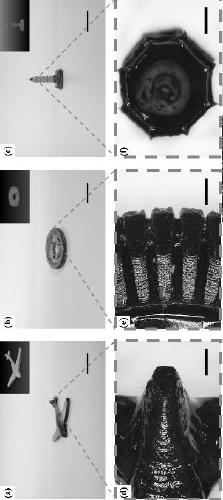

A polyimide and 3D printing technology, applied in the field of 3D printing, can solve the problems of loss of high-strength and high-temperature performance of polyimide, lower fidelity of printed products, low thermal expansion coefficient, etc., and achieve superior shape memory performance, good mechanical The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A kind of preparation method of photocurable polyimide ink for 3D printing, comprises the following steps:

[0033] ⑴Preparation of copolymerized polyimide:

[0034] Under nitrogen atmosphere, add N-methyl-2-pyrrolidone (28mL) to 3,5-diaminobenzoic acid (5mmol, 0.746g) and stir until 3,5-diaminobenzoic acid is completely dissolved; then slowly add 4 , 4'-(4,4'-isopropyldiphenoxy) diphthalic anhydride (10mmol, 5.2g), continuously stirred in an ice bath for 20~30h to obtain a mixed solution, which was added with 4,4 'Diaminodiphenyl ether (5mmol, 1.001g) was continuously stirred for 20~30 h to obtain a black polyamic acid solution; the black polyamic acid solution was heated to 240~290°C and stirred for 2~5 h for imidization reaction, In this process, the water molecules produced are removed by a water separator, and finally a black viscous copolyimide solution is obtained. The copolyimide solution is precipitated with absolute ethanol, washed repeatedly with ...

Embodiment 2

[0039] Embodiment 2 A kind of preparation method of photocurable polyimide ink for 3D printing, comprises the following steps:

[0040] (1) Preparation of copolyimide is the same as in Example 1.

[0041] (2) The polyimide grafted with methacrylate is prepared with embodiment 1.

[0042] (3) Preparation of photocurable polyimide ink:

[0043] Dissolve acrylate-grafted polyimide (20wt%) into N-vinyl-2-pyrrolidone (78wt%), then add inhibitor hydroquinone (0.1wt%), photoinitiator Irgacure 2100 (1.9wt%) and stirred for 10 minutes to obtain 3D printed shape memory polyimide ink.

Embodiment 3

[0044] Embodiment 3 A kind of preparation method of photocurable polyimide ink for 3D printing, comprises the following steps:

[0045] (1) Preparation of copolyimide is the same as in Example 1.

[0046] (2) The polyimide grafted with methacrylate is prepared with embodiment 1.

[0047] (3) Preparation of photocurable polyimide ink:

[0048] Dissolve acrylate-grafted polyimide (20wt%) into N-vinyl-2-pyrrolidone (74wt%), and then add the cross-linking monomer isobornyl methacrylate (4wt%), polymerization inhibitor Agent hydroquinone (0.1wt%) and photoinitiator Irgacure 2100 (1.9wt%) were stirred for 25 minutes to obtain 3D printed shape memory polyimide ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com