Polyimide oligomer capable of quick photocuring and preparation method and application thereof

A polyimide, photocuring technology, applied in the direction of organic chemistry, coating, etc., can solve the problem of poor solubility of pre-imidized polyimide, and achieve the effect of less solvent types, easy operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

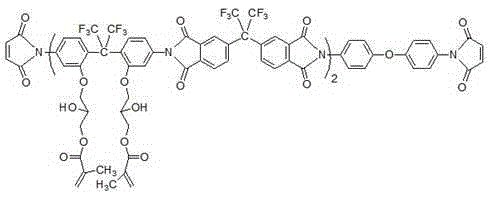

[0031] Structural formula of fast photocurable polyimide oligomer poly(FOPI-MA):

[0032]

[0033] Preparation of poly(FOPI-MA):

[0034] At 5°C, 36.6g of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, 40.0g of 4,4'-diaminodiphenyl ether, 77.5g of 3 , 3',4,4'-Diphenyl ether tetra-acid dianhydride and 9.8g maleic anhydride, stirred for 2 hours, then heated to 130°C for 4 hours, continued to heat to 200°C and refluxed for 2 hours, distilled off 500mL of solvent Continue to heat and reflux at 200°C for 12 hours, cool the reaction solution to room temperature, then add 105mg triethylamine, 220mg tetraethylammonium bromide and 1.5g hydroquinone, stir well and add 42.6g glycidyl methacrylate Ester, heated to 100°C for 4 hours, cooled to room temperature, poured the reaction liquid into 2.0L absolute ethanol to precipitate solid matter, filtered and washed once with 2L distilled water, then washed once with 1L absolute ethanol, Vacuum drying at 45° C. yielded 148 g of polyim...

Embodiment 2

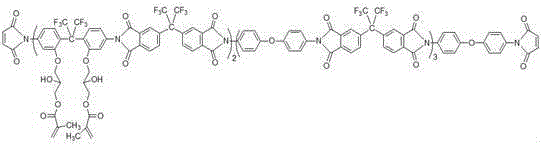

[0038] Structural formula of fast photocurable polyimide oligomer poly(FFPI-MA):

[0039]

[0040] Preparation of poly(FFPI-MA):

[0041] At 5°C, add 36.6g 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, 40.0g 4,4'-diaminodiphenyl ether, 111.0g2 , 2'-bis(3,4-dicarboxyphenyl)hexafluoropropanecarboxylic dianhydride and 9.8g maleic anhydride, stirred for 2 hours, then raised to 150°C for 2 hours, continued heating to 210°C and refluxed for 3 hours, After distilling off 1200mL of solvent, continue to heat and reflux at 210°C for 4 hours, cool the reaction solution to room temperature, then add 105mg of triethylamine, 220mg of tetraethylammonium bromide and 1.5g of hydroquinone, stir well and then add 42.6g Glycidyl methacrylate, heated to 100°C for 4 hours, cooled to room temperature, poured the reaction liquid into 4L of absolute ethanol to precipitate solids, washed with 4L of distilled water and 2L of absolute ethanol for 2 times after filtration , and dried under vacuu...

Embodiment 3

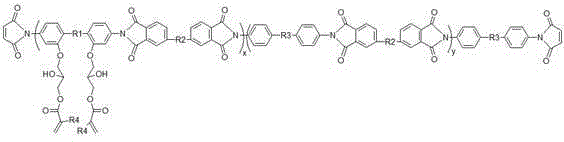

[0045] Structural formula of fast photocurable polyimide oligomer poly(SFPI-MA):

[0046]

[0047] Preparation of poly(SFPI-MA):

[0048] At 0°C, add 84.1g of 3,3'-diamino-4,4'-dihydroxydiphenylsulfone and 116.9g of 1,4-bis(4-aminophenoxy)benzene to 5000mL of N-methyl-2-pyrrolidone , 266.5g of 2,2'-bis(3,4-dicarboxyphenyl)hexafluoropropanecarboxylic dianhydride and 9.8g of maleic anhydride, stirred for 4 hours, then raised to 150°C for 3 hours, and continued to heat to 210°C to reflux for 4 hours Hours later, after distilling off 2000mL of solvent, continue to heat and reflux at 210°C for 4 hours, cool the reaction solution to room temperature, then add 160mg of triethylamine, 340mg of tetraethylammonium bromide and 2.0g of hydroquinone, and stir evenly Add 85.3g of glycidyl methacrylate, heat to 100°C and react for 5 hours. After cooling to room temperature, pour the reaction liquid into 5L of absolute ethanol to precipitate solid matter. After filtering, wash with 4L of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com