ppf/ppf-da light curing material bone tape

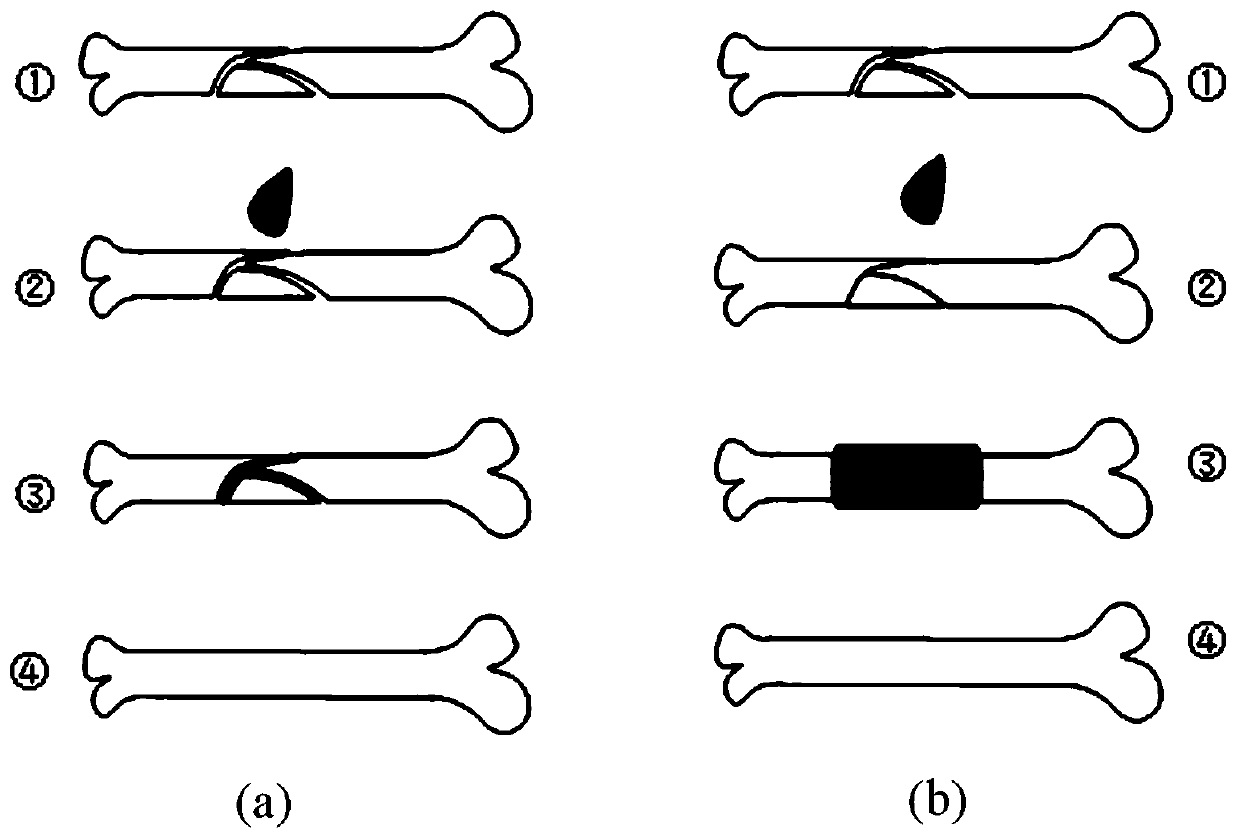

A PPF-DA, light-curing material technology, applied in surgery, surgical adhesives, medical science, etc., can solve the problems of delaying the growth and self-healing of new bone tissue, not treating comminuted fractures, and easily damaged tissues and cells. , to achieve the effect of short curing time, less heat release and easy coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1: ① Weigh 0.50g component A (PPF) and 1.04g component B (PPF-DA) respectively, the double bond ratio of component A to component B is 1:2, if the viscosity of PPF and PPF-DA Larger, inconvenient to measure, first adjust the temperature to 30°C in a vacuum drying oven and heat for 5 minutes to reduce the viscosity, which is convenient to measure, and use the same Erlenmeyer flask when measuring. The weighed components A and B were dissolved in 20 mL of dry dichloromethane and mixed to obtain a mixed solution. ②Stir the mixed solution with a magnetic stirrer and continue stirring for 0.5h. After stirring, remove the magnet. The mixed solution was rotary evaporated under vacuum conditions (-0.06MPa), the temperature was set at 37°C, and the rotary evaporation continued for 1h. ③Seal the mouth of the Erlenmeyer flask containing the mixture after rotary evaporation with coarse filter paper to prevent volatilization of the mixture, put it in a vacuum drying oven, a...

example 2

[0027]Example 2: ① Weigh 1.00g of component A (PPF) and 1.73g of component B (PPF-DA) respectively, the double bond ratio of component A to component B is 3:5, if the viscosity of PPF and PPF-DA Larger, inconvenient to measure, first adjust the temperature to 30°C in a vacuum drying oven and heat for 5 minutes to reduce the viscosity, which is convenient to measure, and use the same Erlenmeyer flask when measuring. The weighed components A and B were dissolved in 20 mL of dry dichloromethane and mixed to obtain a mixed solution. ②Stir the mixed solution with a magnetic stirrer and continue stirring for 0.5h. After stirring, remove the magnet. The mixed solution was rotary evaporated under vacuum conditions (-0.06MPa), the temperature was set at 37°C, and the rotary evaporation continued for 1h. ③Seal the mouth of the Erlenmeyer flask containing the mixture after rotary evaporation with coarse filter paper to prevent volatilization of the mixture, put it in a vacuum drying ov...

example 3

[0029] Example 3: ① Weigh 1.00g of component A (PPF) and 1.39g of component B (PPF-DA) respectively, the double bond ratio of component A to component B is 3:4, if the viscosity of PPF and PPF-DA Larger, inconvenient to measure, first adjust the temperature to 30°C in a vacuum drying oven and heat for 5 minutes to reduce the viscosity, which is convenient to measure, and use the same Erlenmeyer flask when measuring. The weighed components A and B were dissolved in 20 mL of dry dichloromethane and mixed to obtain a mixed solution. ②Stir the mixed solution with a magnetic stirrer and continue stirring for 0.5h. After stirring, remove the magnet. The mixed solution was rotary evaporated under vacuum conditions (-0.06MPa), the temperature was set at 37°C, and the rotary evaporation continued for 1h. ③Seal the mouth of the Erlenmeyer flask containing the mixture after rotary evaporation with coarse filter paper to prevent volatilization of the mixture, put it in a vacuum drying o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com