Preparation method of graphene/polyacrylic ester-silicon-containing hyperbranched waterborne polyurethane multi-element composite emulsion

A hyperbranched polyurethane and polyacrylate technology, which is applied in the field of polymer materials, can solve the problems of weak force and low force interaction, etc., and achieve the effects of increased hydrophobicity, improved mechanical properties, and easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

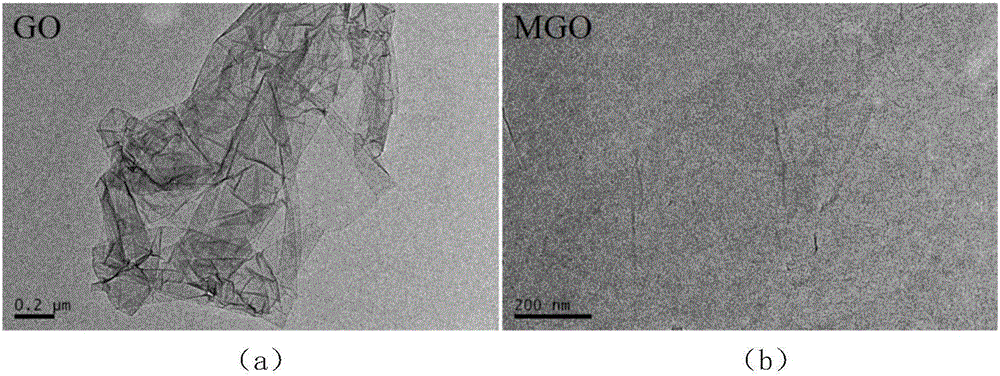

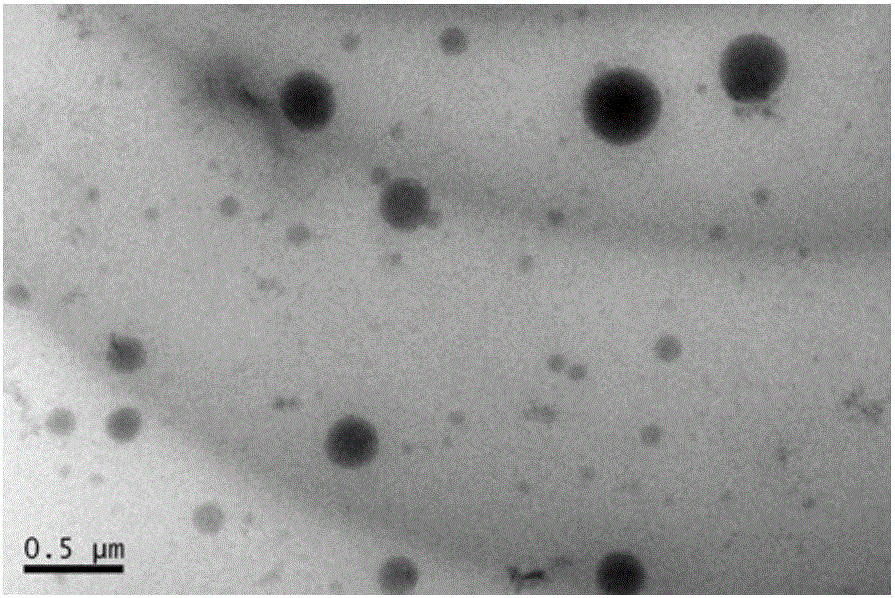

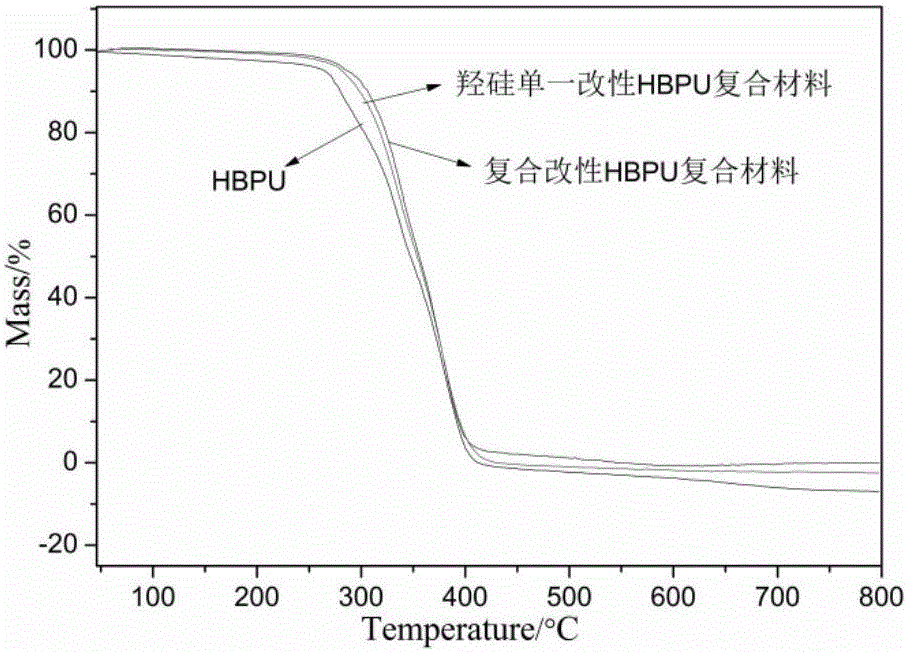

[0048] 1. Preparation of graphene oxide GO: under ice-water bath cooling, graphite powder (3g), sodium nitrate (1g), concentrated sulfuric acid (75mL) were mixed and stirred for 1min, and potassium permanganate (9g) was slowly added step by step, about After 1.5h, the stirring was continued for 1h, and the temperature was kept at 30-40°C for 2d. Slowly add 150 mL of deionized water for dilution, add 450 mL of water and continue to stir, then slowly add 20 mL of 30% hydrogen peroxide solution dropwise, add 200 mL of 1 mol / L dilute hydrochloric acid solution after fully stirring for washing, let stand, and precipitate. After removing the supernatant, use a large amount of deionized water for repeated washing, centrifugation, and precipitation until the solution is weakly acidic (pH ≈ 5~7), ultrasonically stripped for more than 4 hours using a high-power ultrasonic scrubber, and centrifuged at a high speed of 12000r / min. , and take the supernatant, the GO dispersion. For further...

Embodiment 2

[0060] 1. Preparation of graphene oxide GO: under ice-water bath cooling, graphite powder (3g), sodium nitrate (1g), concentrated sulfuric acid (75mL) were mixed and stirred for 1min, and potassium permanganate (9g) was slowly added step by step, about After 1.5h, the stirring was continued for 1h, and the temperature was kept at 30-40°C for 2d. Slowly add 150 mL of deionized water for dilution, add 450 mL of water and continue to stir, then slowly add 20 mL of 30% hydrogen peroxide solution dropwise, add 200 mL of 1 mol / L dilute hydrochloric acid solution after fully stirring for washing, let stand, and precipitate. After removing the supernatant, use a large amount of deionized water for repeated washing, centrifugation, and precipitation until the solution is weakly acidic (pH ≈ 5~7), ultrasonically stripped for more than 4 hours using a high-power ultrasonic scrubber, and centrifuged at a high speed of 12000r / min. , and take the supernatant, the GO dispersion. For further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com