Organic silicon modified epoxy heat-resistant and anti-corrosive coating and preparation method thereof

An anti-corrosion coating, silicone technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problem of difficult modification of epoxy resin by silicone, and achieve excellent paint film performance and good heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below through examples, but the protection scope of the present invention is not limited thereto.

[0026] A silicone-modified epoxy heat-resistant anti-corrosion coating, which is composed of component A of the coating main agent and component B of the curing agent. The paint main agent is prepared by the following steps:

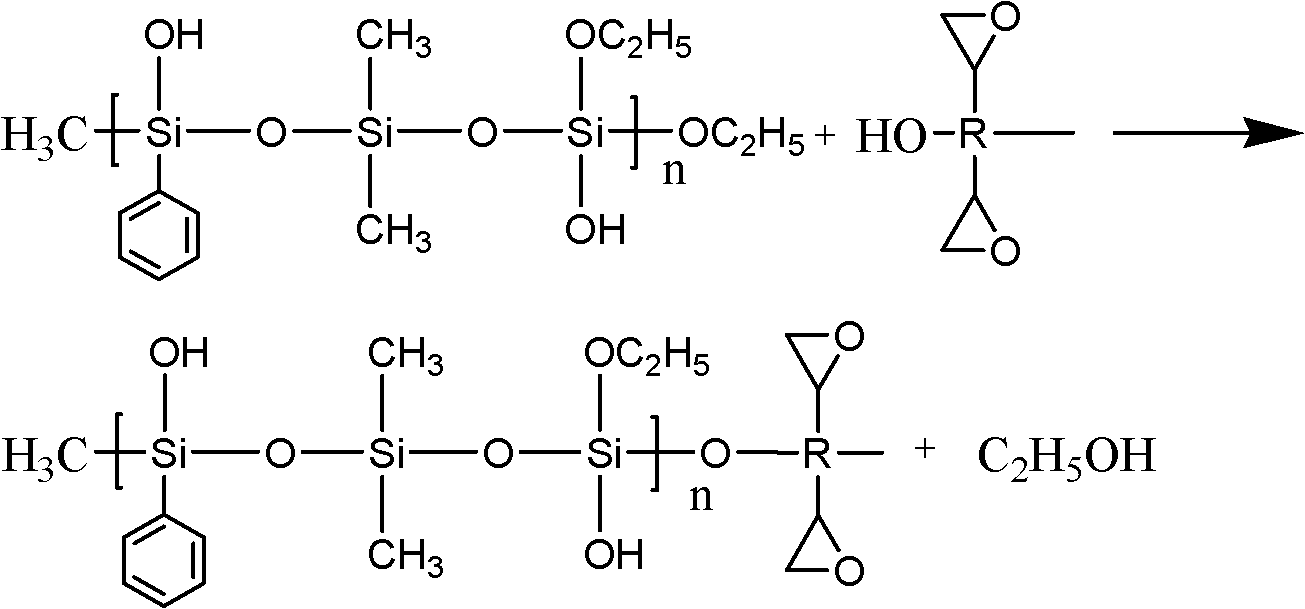

[0027] 1) Using methylphenylsiloxane monomers to synthesize prepolymers to obtain silicone oligomers;

[0028] 2) Using xylene and cyclohexanone as a mixed solvent, adding zinc naphthenate catalyst, epoxy resin E-20 and silicone oligomer reacted at 130°C for 4 hours to obtain a light yellow transparent liquid, and then adding an appropriate amount of solvent to prepare A solution with a solid content of 50% to obtain the base resin;

[0029] Resin reaction formula is as follows table 1:

[0030] Table 1: Raw material formula of organosilicon modified epoxy heat-resistant resin

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com