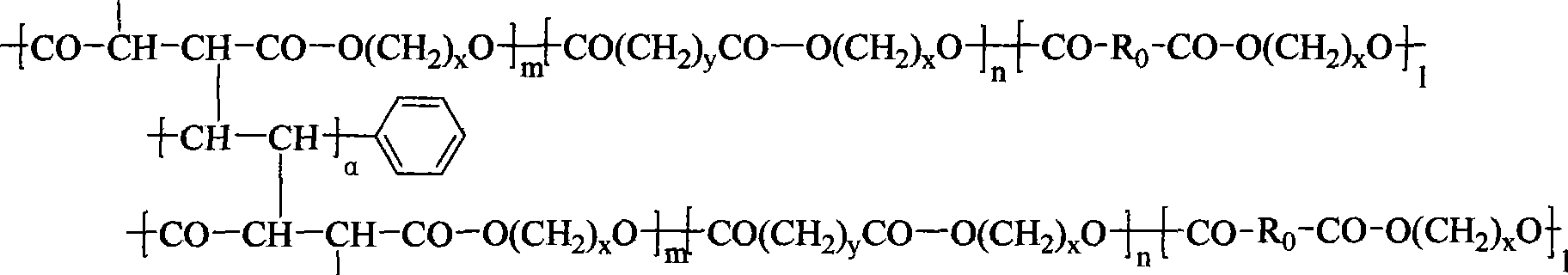

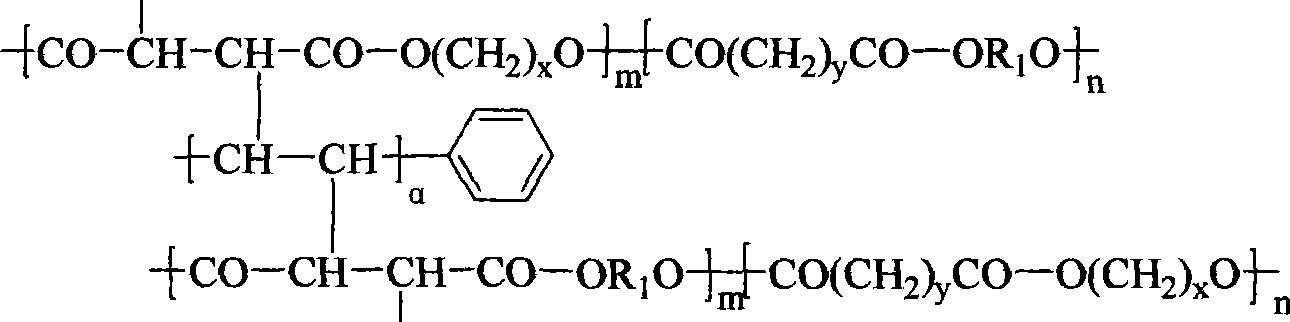

Reaction-type transparent halogen-free flameproof unsaturated polyester and preparation method thereof

An unsaturated and reactive technology, applied in the synthesis field of reactive transparent halogen-free flame retardant unsaturated polyester, to achieve the effect of moderate viscosity and long-term stable electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 102.6 mL of ethylene glycol to the three-necked flask, stir with a magnetic stirrer, and slowly drop 100 mL of phenylphosphoryl dichloride under the condition of ice water cooling. After the reaction was stopped, the excess ethylene glycol was distilled off under reduced pressure at 100° C. to obtain 161.5 g of a colorless liquid flame retardant phenyl di(ethylene glycol) phosphate.

[0036] Take 30g of the above synthesized flame retardant, add 16.6g of phthalic anhydride, 25g of maleic anhydride and 28.4g of propylene glycol, and place them in a 250ml four-necked flask. 2 Stir mechanically under air protection, heat with an electric heating mantle, slowly raise the temperature to 150°C at a rate of 5°C / min, react at a constant temperature for 1 hour, continue to slowly increase the reaction temperature at a rate of 5°C / min, and control the distillation outlet temperature to be lower than 100°C. The heating is stopped when the acid value of the unsaturated polyester is...

Embodiment 2

[0038] A three-necked flask was charged with 192.4 g of resorcinol and 112 mL of xylene. N 2 protection. The temperature was raised to 125°C and refluxed. After the resorcinol was completely melted, it was stirred with a magnetic stirrer, and 113.5g of phenylphosphoryl dichloride was slowly dropped into it. After the addition was completed, the reaction was continued at 125°C for 9 hours. After stopping the reaction, xylene was distilled off under reduced pressure at 120°C. NaHCO for crude products 3 The aqueous solution is washed until no gas is released, and then washed twice with distilled water. After vacuum drying at 45°C for 24 hours, 99.6 g of a reddish-brown liquid flame retardant phenylphosphonate bis(resorcinol) ester was obtained.

[0039] Take 40g of the above synthesized flame retardant, 20.7g of isophthalic anhydride, 12g of maleic acid, 18.6g of propylene glycol and 8.7g of ethylene glycol, and place them in a 250ml four-necked flask. 2 Stir under air protection, he...

Embodiment 3

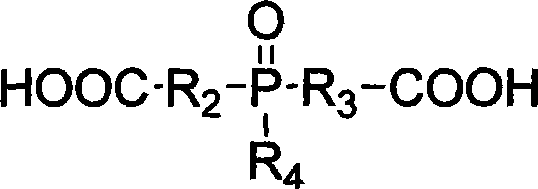

[0041] Melt polycondensation reaction of 100g of fumaric acid, phthalic anhydride, bis(2-carboxyethyl)methyl phosphorous oxide, propylene glycol, and neopentyl glycol with a molar ratio of 2:1:1:2:2 , Heating up to 155°C at a rate of 9°C / min, N 2 Stir mechanically under air protection, react at a constant temperature for 1 hour, then slowly increase the temperature at a rate of 5°C / min, and control the distillation outlet temperature to be lower than 100°C. The acid value of the unsaturated polyester was monitored. At the end of the reaction, the temperature was lowered to 110°C, and 35% of the total mass of the resin, 0.03g tert-butylcatechol and 2g tert-butyl peroxybenzoate were added in sequence to obtain a certain viscosity The light yellow transparent unsaturated polyester product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com