Macrocyclic polyester oligomers and processes for polymerizing the same

a technology of polyester oligomers and macrocyclic polyester, applied in the field processes for polymerizing the same, can solve the problems of limited development of processing equipment for use limited and inability to meet the requirements of the application of macrocyclic polyester oligomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example a

[0190] The macrocyclic polyester oligomers used in the following example are macrocyclic copolyester oligomers with 95.0 mol % of PBT and 5.0 mol % of PET. The macrocyclic copolyester oligomers were prepared by heating a mixture of copolyester linears, organic solvents, such as o-xylene and o-dichlorobenzene, which are substantially free of oxygen and water, and tin or titanium compounds as transesterification catalysts.

[0191] A clean stainless steel reactor equipped with a magnetically coupled stirrer and heater with controls was charged with 4800 ml (4176 grams) of o-xylene, 59.2 grams (0.269 moles) of PBT pellets and 2.72 grams (0.0142 moles) of PET pellets to produce a 0.06 M polymer / o-xylene solution. The solution was heated to 100.degree. C. and sparged with dry nitrogen until the moisture content of water was about 5 ppm. Sparging also removed the dissolved oxygen in the solvent and inerted the reactor. The reactor was then sealed. The mixture was heated to 220.degree. C. Aft...

example 1

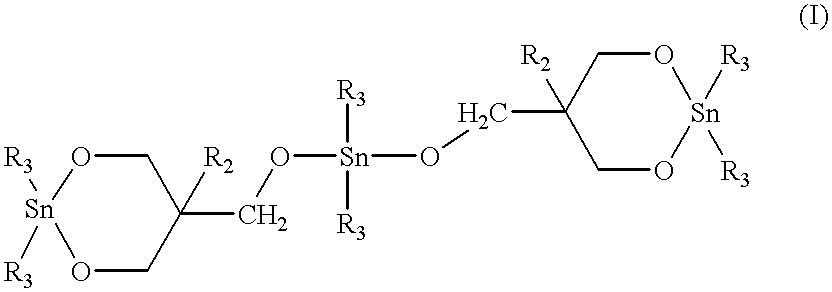

[0192] Twenty milligrams of 1,1,6,6-tetra-n-butyl-1,6-distanna-2,5,7,10-te-traoxacyclodecane ("stannoxane-1") was dissolved with heating in approximately 2.5 ml of toluene which had been pre-dried by treating with 4A molecular sieves. The solution was cooled and poured into a glass jar containing 5.0 g of finely pulverized macrocyclic copolyester oligomer of PBT / PE (95 / 5 molar ratio). After intimately mixing the resulting uniform paste was dried under vacuum at about 50.degree. C. The white crusty solid was pulverized by using a pestle and a mortar. The resulting uniform free flowing white powder contained 0.3 mole % of tin atoms per mole of the copolyester monomer repeat units.

example 2

[0193] Example 1 was repeated except that 33.0 mg of stannoxane-1 catalyst was employed to give a blend containing 0.5 mole % of tin atoms per mole of the copolyester monomer repeat units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com