Preparation method of compact and composite proton exchange membrane

A proton exchange membrane and composite technology, which is applied in the field of preparation of dense composite proton exchange membranes, can solve the problems of complicated operation steps, unfavorable infiltration of microporous membrane resin into micropores, etc., and achieves small particles and convenient membrane extraction. Faster, longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

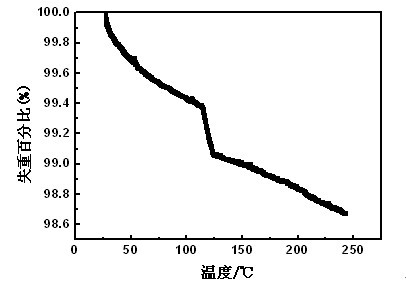

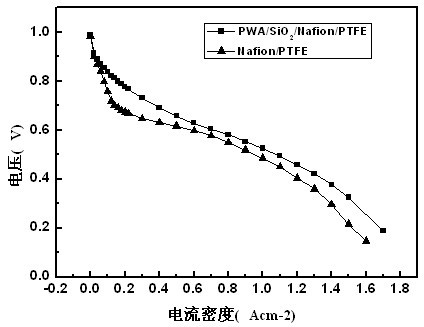

Embodiment 1

[0039] Take 0.8g of perfluorosulfonic acid resin (Nation resin), heat and dissolve the perfluorosulfonic acid resin in an autoclave with 15ml of isopropanol aqueous solution (the volume ratio of isopropanol to water is 2:1) for 5 hours to obtain perfluorosulfonic acid resin Sulfonic acid resin solution;

[0040] Add 3ml of high boiling point solvent N,N-dimethylformamide (DMF) to the perfluorosulfonic acid resin solution and mix to obtain a mixed solution;

[0041] Add silicotungstic acid and fumed silica to the above mixed solution, where the dosages of phosphotungstic acid and fumed silica are respectively 2% and 5% of the mass of Nafion, and ultrasonically disperse uniformly to obtain a uniform mixed solution of perfluorosulfonic acid resin ;

[0042] Soak and wash a polytetrafluoroethylene porous base membrane with a thickness of 10 μm (hereinafter referred to as PTFE porous base membrane) with deionized water and ethanol; coat a layer of release agent on the surface of f...

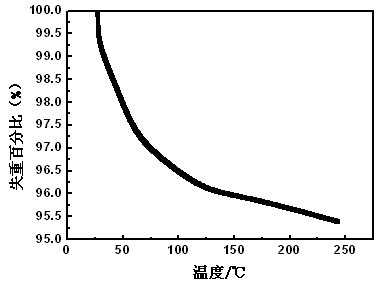

Embodiment 2

[0054] Take 1g of perfluorosulfonic acid resin (Nation resin), heat and dissolve the perfluorosulfonic acid resin in an autoclave for 1 hour with 35ml of propanol aqueous solution (the volume ratio of propanol to water is 4:1) to obtain perfluorosulfonic acid resin solution;

[0055] Add 5ml of high boiling point solvent N,N-dimethylformamide (DMF) to the perfluorosulfonic acid resin solution and mix to obtain a mixed solution;

[0056] Add two water-retaining substances phosphotungstic acid (PWA) and silica sol to the above mixed solution to obtain a mixed solution of perfluorosulfonic acid resin; the amount of PWA is 3% of Nafion resin, and the amount of silica sol is 5% of Nafion resin;

[0057] Soak and wash the PTFE porous base film with a thickness of 10 μm in deionized water and ethanol; coat a layer of release agent on the mirror corrosion-resistant surface, and then spread the PTFE porous base film on the release agent;

[0058] Then drop 2ml of the mixed solution o...

Embodiment 3

[0064] Take 1.5g of perfluorosulfonic acid resin (Nation resin), heat and dissolve the perfluorosulfonic acid resin in an autoclave for 3 hours with 45ml of isopropanol aqueous solution (the volume ratio of isopropanol to water is 8:1), and obtain perfluorosulfonic acid resin Sulfonic acid resin solution;

[0065] Add 5ml of high boiling point solvent N,N-dimethylformamide (DMF) to the perfluorosulfonic acid resin solution and mix to obtain a mixed solution;

[0066] Add fumed silica and PWA to the above mixed solution to obtain a mixed solution of perfluorosulfonic acid resin. Wherein the consumption of fumed silica and PWA is respectively 4% and 6% of Nafion resin;

[0067] Soak and wash the PTFE porous base film with a thickness of 10 μm in deionized water and ethanol; coat a layer of release agent on the surface of the flat glass, and spread the PTFE porous base film on the release agent;

[0068] Drop 1ml of a mixed solution of isopropanol and DMF on the surface of PTFE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com