Modified liquid for filter paper of filter and its preparation method and use

A filter and modified liquid technology, applied in the field of modified liquid, can solve problems such as short service life, filter paper modification treatment, local cloud spots, etc., to improve filtration performance and service life, improve product quality, and use equipment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

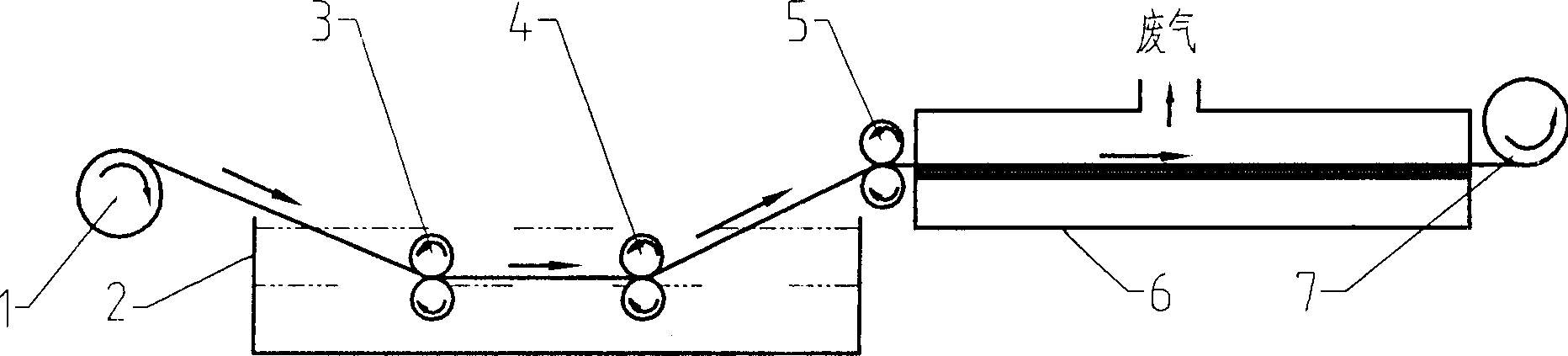

Method used

Image

Examples

Embodiment 1

[0040] After adding 78.9 grams of water to 20 grams of styrene-acrylic emulsion for dilution, add 4 grams of melamine and stir evenly (continuous stirring for 3 minutes), then add 35 grams of polytetrafluoroethylene emulsion and stir uniformly (continuous stirring 3min), and finally, add 10 grams of 10nm titanium dioxide particles and 2 grams of nonylphenol ethoxylate-13, and stir evenly (continuous stirring for 3min), to obtain the filter paper modified liquid of the present invention.

[0041] The filter paper modified liquid prepared by the above method will not deteriorate after sealed storage for one year, and the dynamic viscosity is about 260mPa·s, which is convenient for modifying the filter paper by spraying and dipping.

Embodiment 2

[0043] After adding 51 grams of ethanol to 12 grams of styrene-acrylic emulsion for dilution, add 2 grams of melamine and stir well (continuous stirring for 3 min), then add 25 grams of polytetrafluoroethylene emulsion and stir uniformly (continuous stirring 3min), and finally, add 5 grams of 18nm titanium dioxide particles and 1 gram of nonylphenol ethoxylate-13, and stir evenly (continuous stirring for 3min), to obtain the filter paper modified liquid of the present invention.

[0044] The filter paper modified liquid prepared by the above method will not deteriorate after sealed storage for one year, and its dynamic viscosity is about 280mPa·s. It is convenient to modify the filter paper by two traditional methods of spraying and dipping.

Embodiment 3

[0046] After adding 24 grams of isopropanol to 4 grams of silicone acrylic emulsion for dilution, add 1 gram of melamine and stir evenly (continuous stirring for 3 minutes), then add 15 grams of polytetrafluoroethylene emulsion and stir evenly (continuous stirring for 3 minutes), finally, add 1 gram of 1 μm titanium dioxide particles, 0.1 gram of nonylphenol polyoxyethylene ether-13, and stir evenly (continuous stirring for 3 minutes), the filter paper modified liquid of the present invention can be obtained .

[0047] The filter paper modified liquid prepared by the above method will not deteriorate after sealed storage for one year, and its dynamic viscosity is about 300mPa·s. It is convenient to modify the filter paper by two traditional methods of spraying and dipping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com