Concrete channel permeability-reducing agent and preparation method and purpose thereof

A technology of concrete and anti-seepage agent, applied in the field of concrete channel anti-seepage agent, the preparation field of said concrete channel anti-seepage agent, can solve the problems such as unable to meet the anti-seepage requirements of concrete channels, affecting wide application, and poor anti-seepage effect, Achieve the effects of easy promotion and implementation, simple and easy industrial use, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

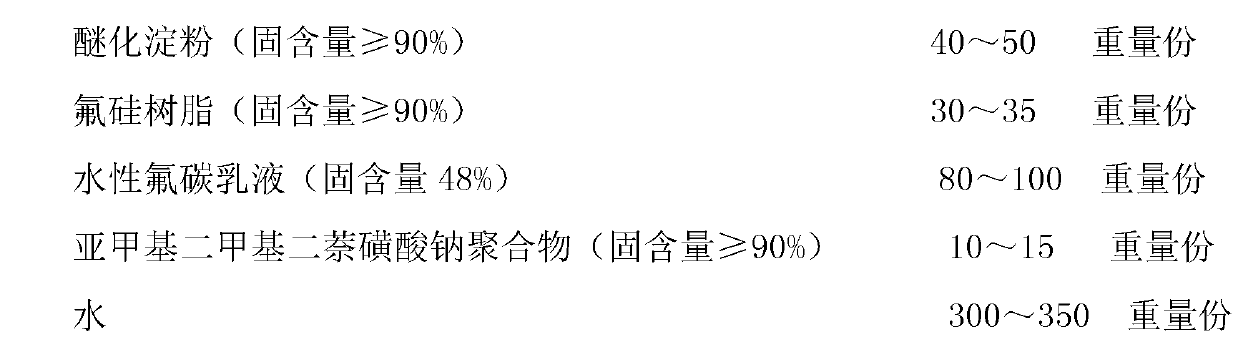

[0035] The preparation method of this anti-seepage agent comprises following two processing steps:

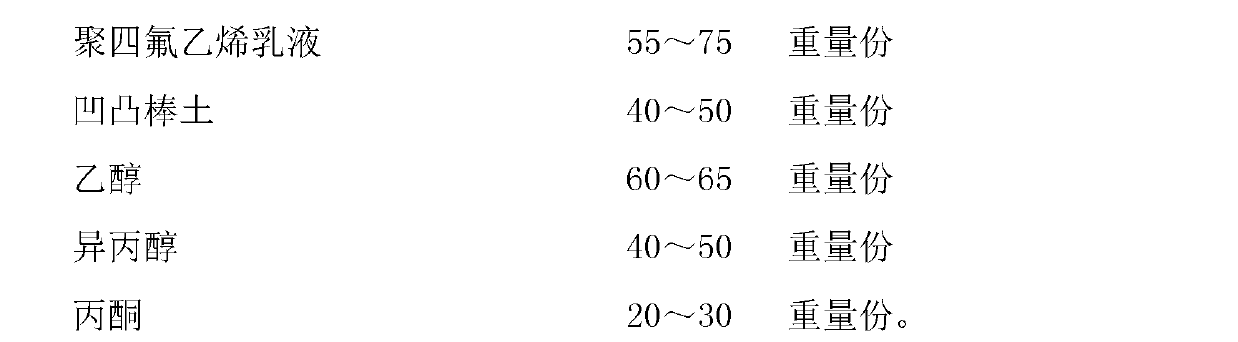

[0036] 1) Add 300 grams of water to 40 grams of etherified starch (solid content 90%) to dissolve, add 10 grams of sodium methylenedimethyl dinaphthalene sulfonate polymer (solid content 90%), and add Warm to 70°C, stir well (continuous stirring for 3min), cool to room temperature, then add 30g of fluorosilicone resin (90% solid content) and 80g of water-based fluorocarbon emulsion (48% solid content), stir well ( Stir continuously for 3min); the fluorosilicone resin (90% solid content) is a synthetic resin made by mixing fluororesin and silicone resin; the water-based fluorocarbon emulsion (48% solid content) is vinyl fluoride and hydroxy vinyl ether Copolymer, the weight percent concentration of fluorine is 8%, and main chain contains fluorine atom, can make described this anti-seepage agent;

[0037] 2) Add 40 grams of attapulgite to a mixed solution consisting of 60 grams ...

Embodiment 2

[0041] The preparation method of this anti-seepage agent comprises following two processing steps:

[0042] 1) Add 325 grams of water to 45 grams of etherified starch (solid content 95%) to dissolve, add 12 grams of sodium methylenedimethyl dinaphthalene sulfonate polymer (solid content 95%), and add Warm to 70°C, stir well (continuous stirring for 3min), cool to room temperature, then add 32 grams of fluorosilicone resin (solid content 95%) and 90 grams of water-based fluorocarbon emulsion (solid content 48%), stir well ( Stir continuously for 3min); the fluorosilicone resin (95% solid content) is a synthetic resin made by mixing fluororesin and silicone resin; the water-based fluorocarbon emulsion (48% solid content) is vinyl fluoride and hydroxy vinyl ether Copolymer, the weight percentage concentration of fluorine is 10%, and main chain contains fluorine atom, can make described this anti-seepage agent;

[0043] 2) Add 45 grams of attapulgite to a mixed solution consistin...

Embodiment 3

[0047] The preparation method of this anti-seepage agent comprises following two processing steps:

[0048] 1) Add 350 grams of water to 50 grams of etherified starch (solid content 98%) to dissolve, add 15 grams of sodium methylenedimethyl dinaphthalene sulfonate polymer (solid content 98%), and Heat to 70°C, stir well (continuous stirring for 3 minutes), cool to room temperature, then add 35 grams of fluorosilicone resin (98% solid content) and 100 grams of water-based fluorocarbon emulsion (48% solid content), and stir well (continuous stirring for 3min); the fluorosilicone resin (98% solid content) is a synthetic resin made by mixing fluororesin and silicone resin; the water-based fluorocarbon emulsion (48% solid content) is vinyl fluoride and hydroxyvinyl Ether copolymer, the weight percentage concentration of fluorine is 11.5%, and main chain contains fluorine atom, can make described this anti-seepage agent;

[0049] 2) Add 43 grams of attapulgite to a mixed solution c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com