Flame retardant treatment agent for filter paper and its preparation method and use

A flame retardant treatment and filter technology, which is used in fiber raw material treatment, papermaking, paper coating, etc., can solve the problems of unsatisfactory flame retardant effect, poor flame retardant effect of paper, and large amount of flame retardant added, and achieves the convenience of Promotion and implementation, good flame retardant effect, and the effect of using less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of this treating agent comprises following two processing steps:

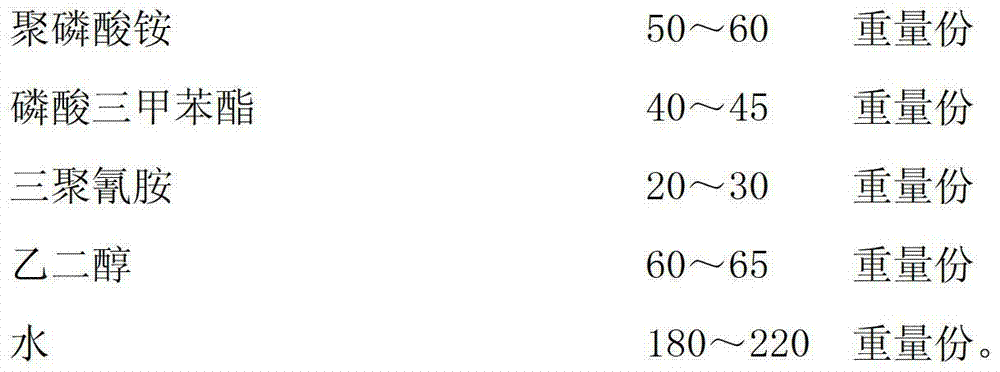

[0047] 1) Add 50 grams of ammonium polyphosphate to 60 grams of ethylene glycol, stir well to dissolve, add 40 grams of tricresyl phosphate, and heat to 60 ° C, after fully stirring, then add 20 grams of melamine, Stir well, then add 180 grams of water to obtain the treatment agent;

[0048] 2) Add 10 grams of zinc borate and 15 grams of aluminum hydroxide to 30 grams of acetic acid, stir thoroughly, and then ultrasonically disperse for 10 minutes to form a suspension, and add the suspension to the prepared treatment agent , stir well.

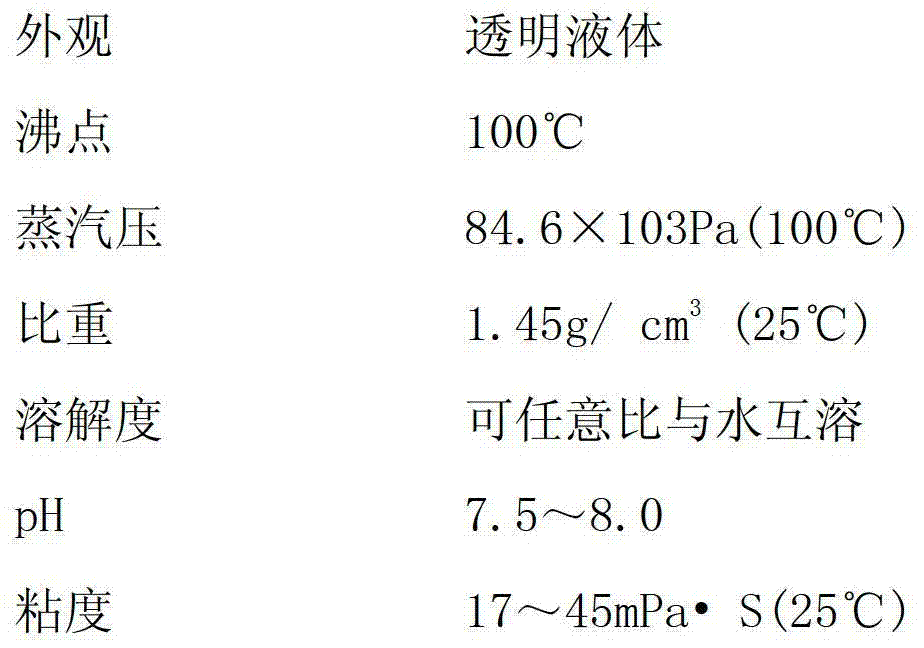

[0049] The treatment agent prepared by the above-mentioned method is easy to store. It only needs to be stored in a place above 5°C, away from direct sunlight, in a cool and dry place with ventilation, and it will not deteriorate in sealed storage for one year.

[0050] The traditional method of electrostatic spraying is used to form a layer of f...

Embodiment 2

[0052] The preparation method of this treating agent comprises following two processing steps:

[0053]1) Add 60 grams of ammonium polyphosphate to 65 grams of ethylene glycol. After fully stirring and dissolving, add 45 grams of tricresyl phosphate and heat to 60°C. After fully stirring, add 30 grams of melamine. Stir well, then add 220 grams of water to obtain the treatment agent;

[0054] 2) Add 15 grams of zinc borate and 20 grams of aluminum hydroxide to 40 grams of acetic acid, stir thoroughly, and then ultrasonically disperse for 10 minutes to form a suspension, and add the suspension to the prepared treatment agent , stir well.

[0055] The treatment agent prepared by the above-mentioned method is easy to store. It only needs to be stored in a place above 5°C, away from direct sunlight, in a cool and dry place with ventilation, and it will not deteriorate in sealed storage for one year.

[0056] The traditional method of dip coating is used to form a layer of flame-r...

Embodiment 3

[0058] The preparation method of this treating agent comprises following two processing steps:

[0059] 1) Add 55 grams of ammonium polyphosphate to 63 grams of ethylene glycol, stir and dissolve, add 43 grams of tricresyl phosphate, and heat to 60 ° C, after fully stirring, then add 23 grams of melamine, Thoroughly stir, then add 190 grams of water to obtain the treatment agent;

[0060] 2) Add 13 grams of zinc borate and 18 grams of aluminum hydroxide to 33 grams of acetic acid, stir thoroughly, and then ultrasonically disperse for 10 minutes to form a suspension, and add the suspension to the prepared treatment agent , stir well.

[0061] The treatment agent prepared by the above-mentioned method is easy to store. It only needs to be stored in a place above 5°C, away from direct sunlight, in a cool and dry place with ventilation, and it will not deteriorate in sealed storage for one year.

[0062] The traditional method of brushing is used to form a layer of flame-retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com