Starch solution and preparation thereof

A starch and solution technology, applied in the preparation of the starch solution, in the field of starch solution, to achieve the effect of using less equipment, proper retention and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

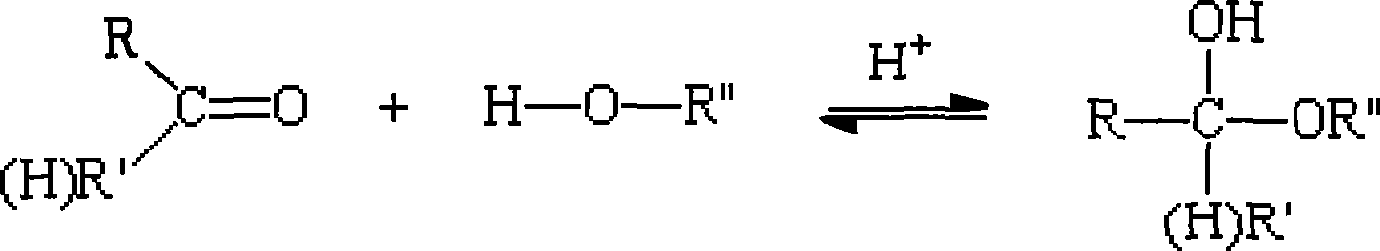

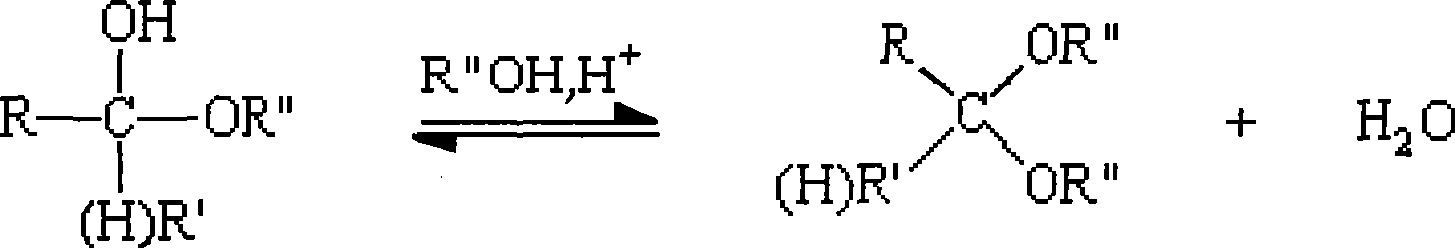

Method used

Image

Examples

Embodiment 1

[0055] Add 450 grams of water to 200 grams of modified starch to dissolve, add 40 grams of polyvinyl alcohol, and heat to 90 ° C, stir well (continuous stirring for 3 minutes), finally, add 55 grams of p-toluenesulfonic acid aqueous solution , 60 grams of formaldehyde, and stir evenly (continuous stirring 3min), modified starch adopts oxidized starch, the weight percent concentration of p-toluenesulfonic acid aqueous solution is 15%, and the weight percent concentration of formaldehyde is 37%, can make this solution.

Embodiment 2

[0057] Add 500 grams of water to 250 grams of modified starch to dissolve, add 45 grams of polyvinyl alcohol, and heat to 90 ° C, stir well (continuous stirring for 3 minutes), finally, add 60 grams of p-toluenesulfonic acid aqueous solution , 80 grams of formaldehyde, and stir evenly (continuous stirring 3min), modified starch adopts oxidized starch, the weight percent concentration of p-toluenesulfonic acid aqueous solution is 15%, and the weight percent concentration of formaldehyde is 37%, can make this solution.

Embodiment 3

[0059] Add 550 grams of ethanol to 300 grams of modified starch to dissolve, add 50 grams of polyvinyl alcohol, and heat to 90 ° C, stir well (continuous stirring for 3 minutes), and finally, add 75 grams of p-toluenesulfonic acid aqueous solution , 100 grams of formaldehyde, and stir evenly (continuous stirring 3min), modified starch adopts oxidized starch, the weight percent concentration of p-toluenesulfonic acid aqueous solution is 15%, and the weight percent concentration of formaldehyde is 37%, can make this solution.

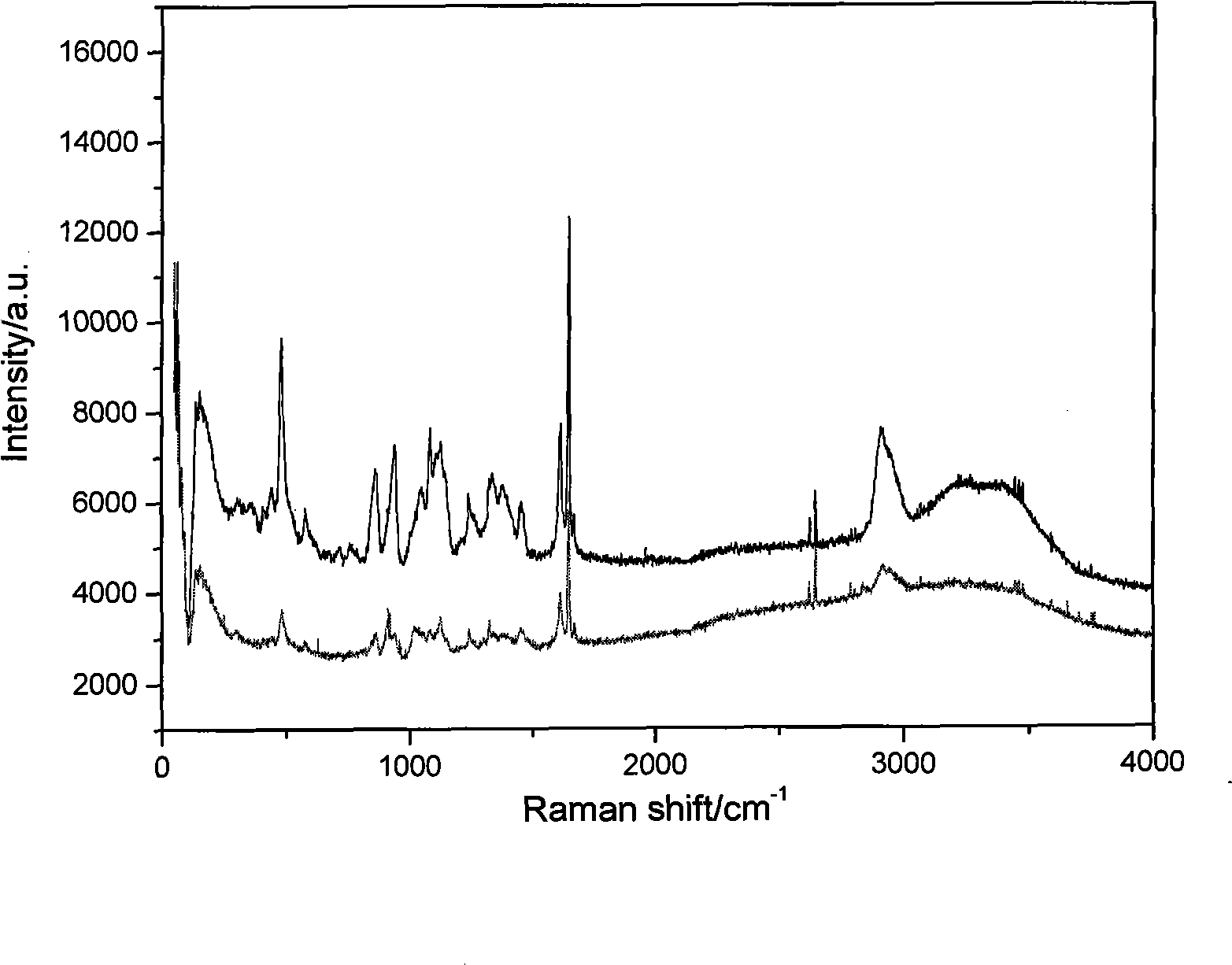

[0060] see figure 1 , the upper and lower lines are the Raman spectrum analysis results of the existing modified starch solution and the solution described in Example 3 of the present invention. From figure 1 It can be seen that the positions of the characteristic peaks of the existing modified starch solution and this solution are basically the same, which shows that the characteristic groups of the two solutions are basically the same, and the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com