Metal surface treating agent substituting for phosphorizing liquid as well as preparation method of metal surface treating agent

A technology of metal surface treatment and phosphating solution, which is applied in the direction of metal material coating process, etc., can solve the problems of difficulty in meeting the requirements of wastewater discharge standards, low chemical oxygen demand and biochemical oxygen demand, and high content of inorganic phosphorus in phosphating wastewater , to achieve the effect of easy promotion and implementation, strong adaptability, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

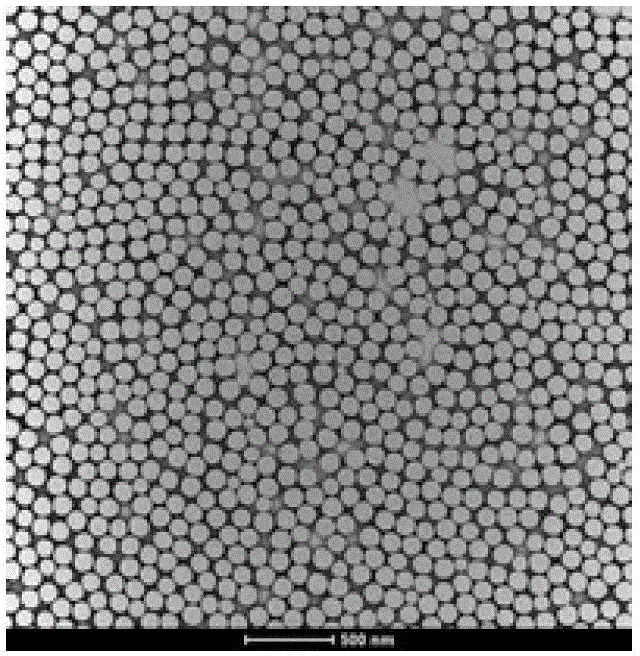

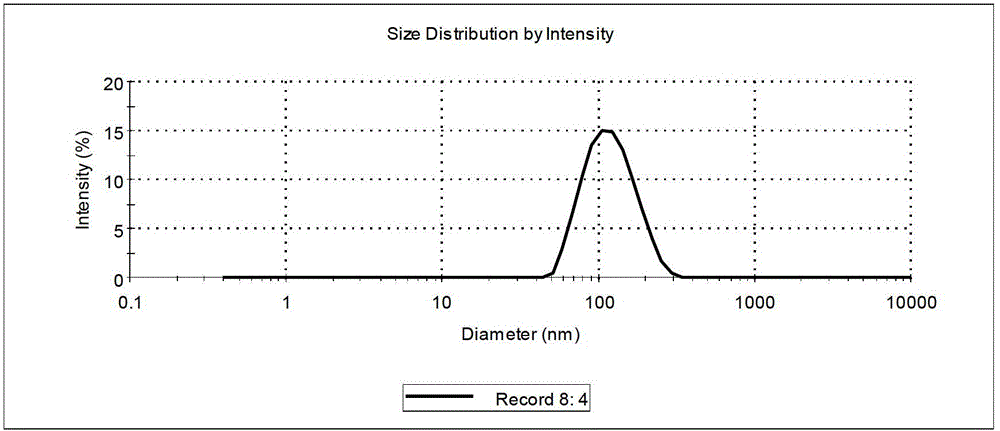

Image

Examples

Embodiment 1

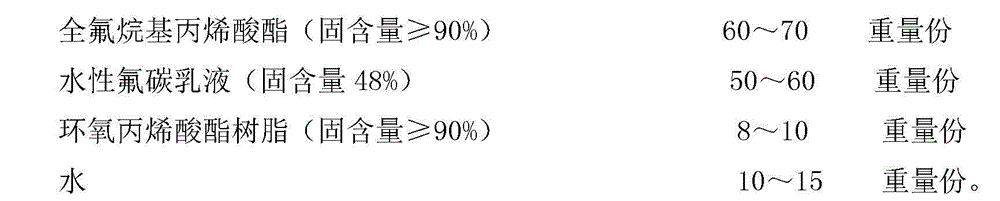

[0034] Add 55 parts by weight of aqueous fluorocarbon emulsion (solid content 48%) and 9 parts by weight of epoxy acrylate resin (solid content 90%) to 65 parts by weight of perfluoroalkyl acrylate (solid content 90%) , 13 parts by weight of water, and fully stirred and dissolved, then added the suspension, and stirred evenly, to obtain the metal surface treatment agent that replaces the phosphating solution, and the preparation method of the suspension is: 1.3 parts by weight of polyvinylpyrrolidone is added to 28 parts by weight of absolute ethanol and fully stirred, then respectively added 9 parts by weight of micron or nanoscale zinc powder, 6 parts by weight of micron or nanoscale glass flakes, fully stirred, Sonicate for an additional 40 minutes to form a suspension.

[0035] The treatment agent prepared by the above-mentioned method is easy to store. It only needs to be stored in a place above 5°C, avoiding direct sunlight, ventilated, cool and dry, and sealed for stora...

Embodiment 2

[0045] Add 55 parts by weight of aqueous fluorocarbon emulsion (solid content 48%) and 9 parts by weight of epoxy acrylate resin (solid content 95%) to 65 parts by weight of perfluoroalkyl acrylate (solid content 95%) , 13 parts by weight of water, and after fully stirring and dissolving, the metal surface treatment agent for replacing the phosphating solution can be obtained.

[0046] The treatment agent prepared by the above-mentioned method is easy to store. It only needs to be stored in a place above 5°C, away from direct sunlight, in a cool and dry place with ventilation, and it will not deteriorate for one year in sealed storage.

[0047] Use the prepared treatment agent and adopt the traditional method of dipping to form a layer of good antirust film on the surface of metal workpieces (such as the metal threaded cover plate of the filter) to complete the antirust treatment of metal workpieces. The dipping temperature is 30 ℃, the immersion time is 60 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com