Anti-corrosion antifouling coating and preparing method thereof

A corrosion-resistant and anti-fouling technology, which is applied in the field of corrosion-resistant and anti-fouling coatings and its preparation, can solve problems such as accelerated corrosion, and achieve the effects of low cost, good safety, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

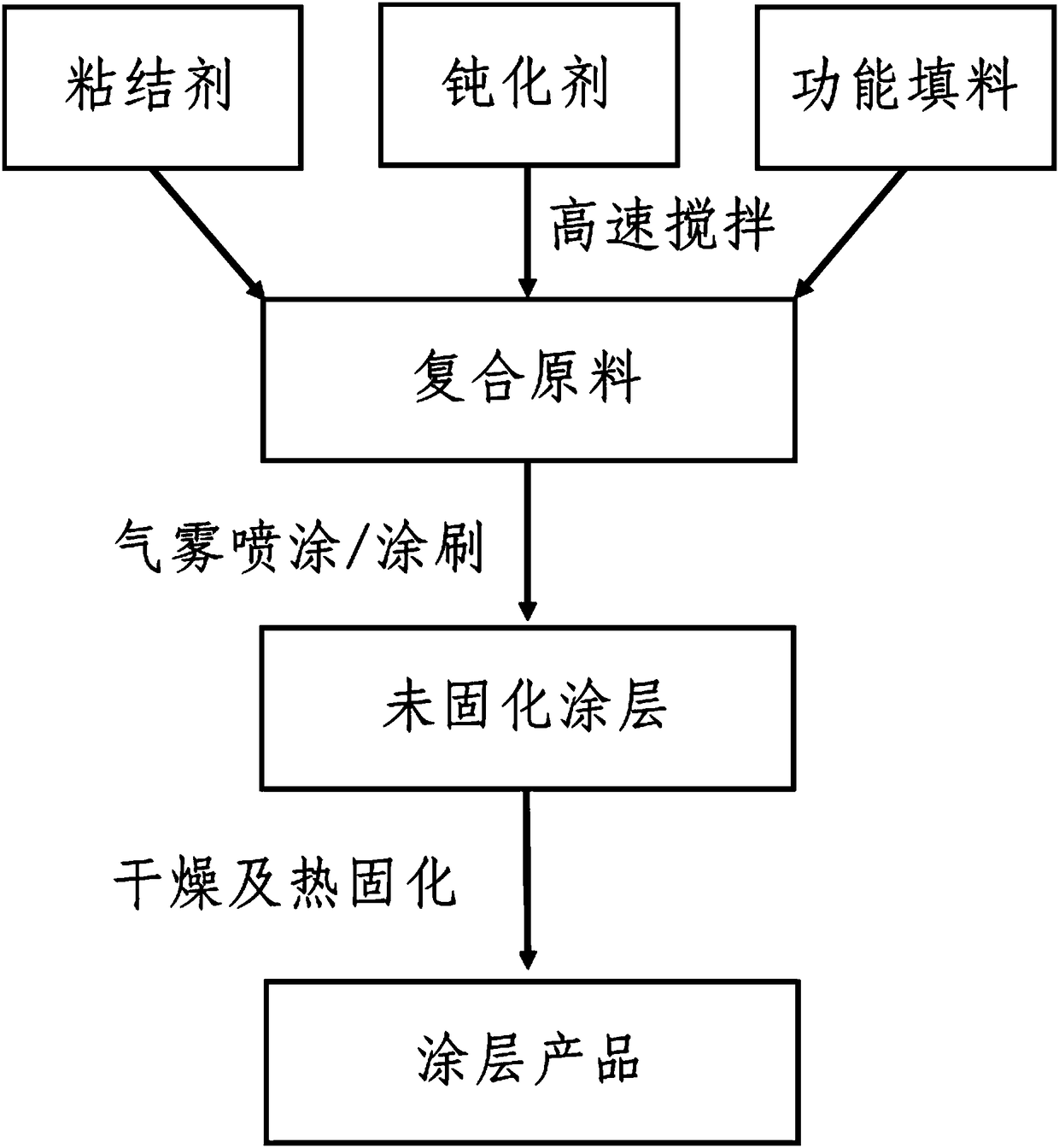

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of inorganic anti-corrosion and anti-fouling raw materials:

[0044] Select 30wt% aluminum dihydrogen phosphate aqueous solution (60g) as binding agent, chromium oxide (13g) is passivator, aluminum powder (particle size is 2 μm, 100g) is corrosion-resistant functional filler and P25 powder (particle size 25nm, 80g ) is a photocatalytic functional filler, which is added into 50ml of deionized water, and stirred at a high speed for 0.5h (rotating speed 1000r / min), so that the components of the raw materials are evenly dispersed and compounded.

[0045] (2) Substrate pretreatment: Degrease and derust the surface of the low carbon steel of the substrate material, and perform sandblasting on the surface.

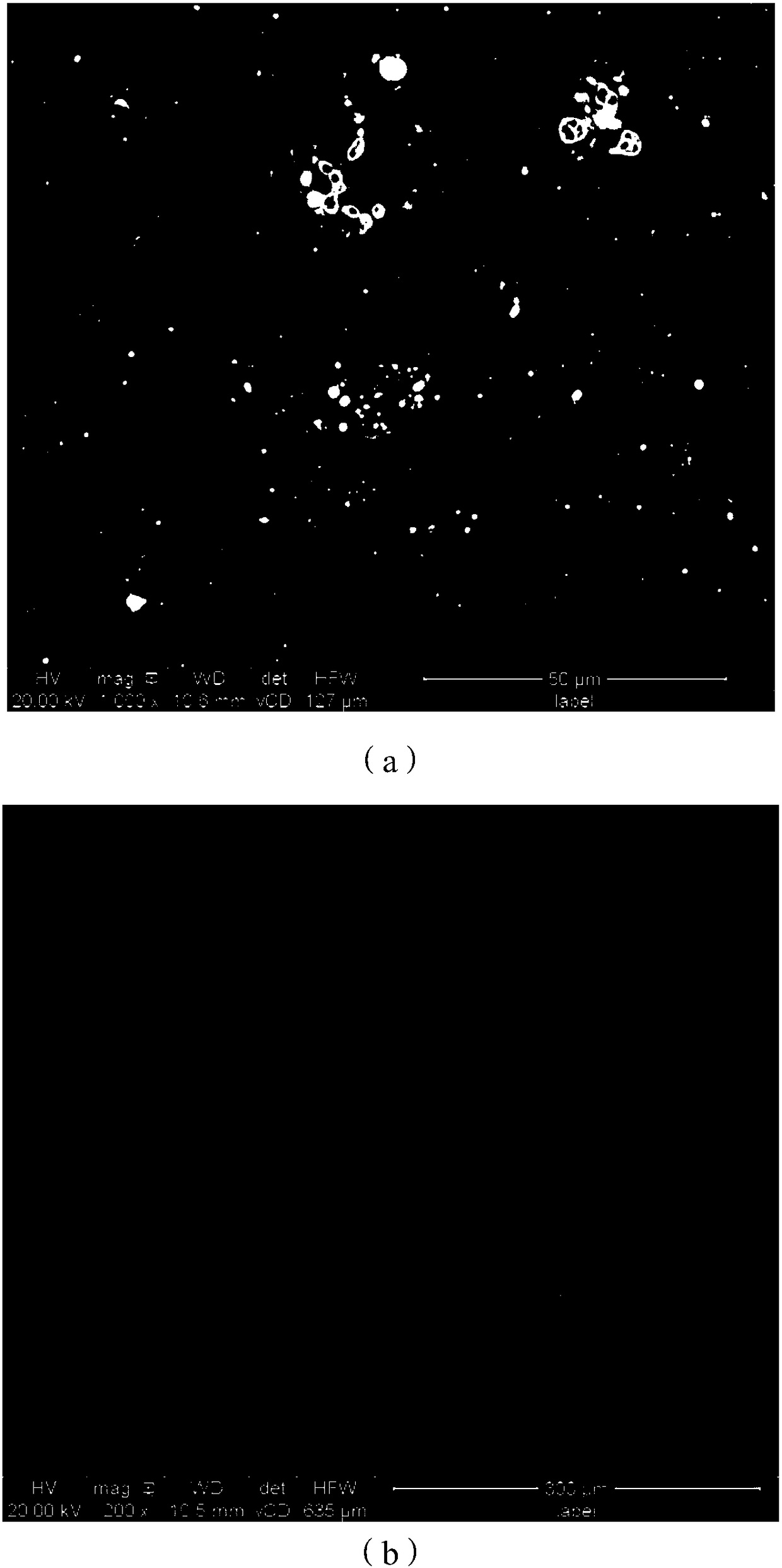

[0046] (3) Coating preparation: A layer of 100 μm inorganic corrosion-resistant and anti-fouling coating was prepared on the surface of the pretreated substrate by means of aerosol spraying, and cured by heating. Among them, the aerosol spraying parameters...

Embodiment 2

[0074] (1) Preparation of inorganic anti-corrosion and anti-fouling raw materials:

[0075] Select 30wt% aluminum dihydrogen phosphate aqueous solution (60g) as binding agent, sodium silicate (20g) is passivating agent, aluminum powder (particle size is 2 μm, 80g) is corrosion-resistant functional filler, P25 powder (particle size 25nm, 120g) is a photocatalytic functional filler, which is added to 50ml of deionized water, and stirred at a high speed for 1h (rotating speed 1000r / min), so that the components of the raw materials are evenly dispersed and compounded.

[0076] (2) Substrate pretreatment: Degrease and derust the surface of the substrate material, and perform sandblasting on the surface.

[0077] (3) Coating preparation: A layer of 200 μm inorganic corrosion-resistant and anti-fouling coating was prepared on the surface of the pretreated substrate by means of aerosol spraying, and cured by heating. Among them, the aerosol spraying parameters are air pressure of 0.8...

Embodiment 3

[0088] (1) Preparation of inorganic anti-corrosion and anti-fouling raw materials:

[0089] Choose 30wt% aluminum dihydrogen phosphate aqueous solution (55g) as binder, sodium silicate (15g) as passivator, zinc powder (particle size is 2μm, 100g) as corrosion-resistant functional filler, Ag-doped anatase phase TiO 2 The powder (particle size 5-10nm, 80g) is a photocatalytic functional filler, added to 50ml of deionized water, and stirred at a high speed for 1.5h (rotating speed 800r / min), so that the components of the raw materials are evenly dispersed and compounded.

[0090] (2) Substrate pretreatment: Degrease and derust the surface of the substrate material, and perform sandblasting on the surface.

[0091] (3) Coating preparation: use a brushing roller to paint, prepare an inorganic corrosion-resistant and anti-fouling coating with a thickness of 60 μm on the surface of the pretreated substrate, and heat and cure. Among them, the single coating thickness of the brushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com