Preparation method of silver nanowire film heater resistant to repeated scraping

A thin film heater and silver nanowire technology, which is applied in the direction of ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of scratch resistance, etc., and achieve the effect of improving scratch resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

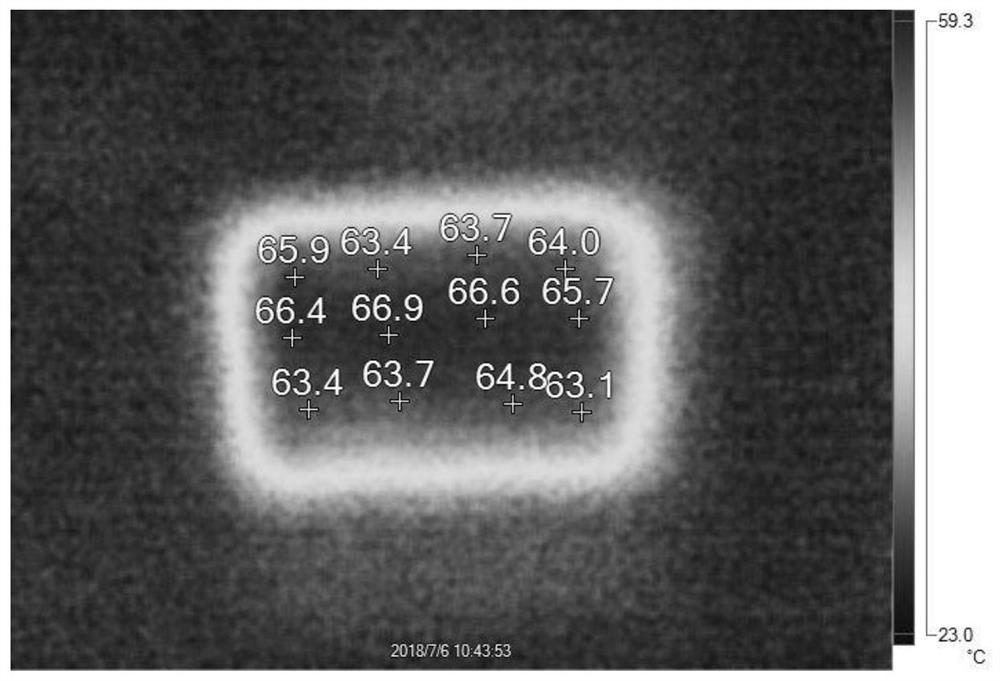

[0021] A method for preparing a silver nanowire film heater resistant to repeated scratches, comprising the steps of:

[0022] Step 1: Disperse the silver nanowires synthesized by the polyol method in an ethanol solution to obtain a silver nanowire colloid with a concentration of 2.5 mg / mL.

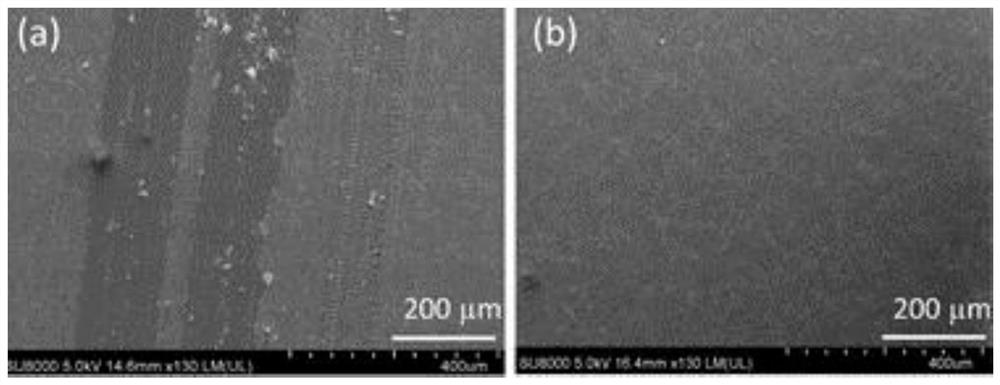

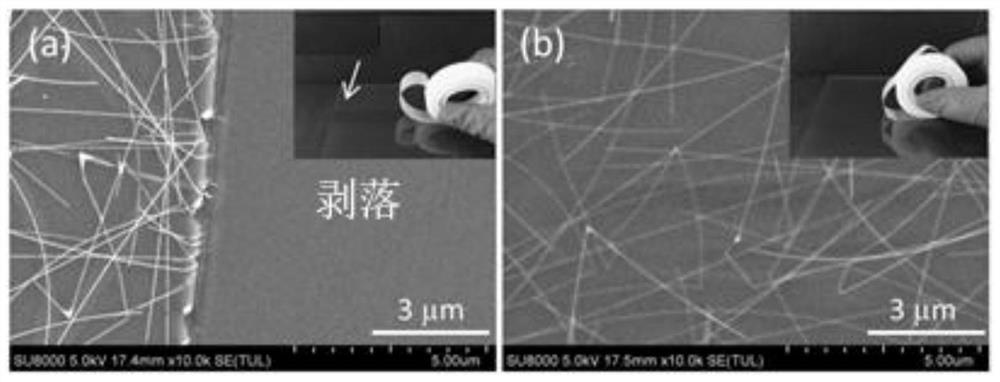

[0023] Step 2: Coating the silver nanowire colloid on the high-temperature-resistant substrate by scraping, spraying, spin coating and other techniques to obtain a silver nanowire film. The high-temperature-resistant substrate is flat or curved glass or ceramics, and the substrate is ultrasonically cleaned in acetone, ethanol, and deionized water for 20-30 minutes in advance. The film is composed of silver nanowire grids to form conductive channels, and the resistance of the silver nanowire film is optional in the range of 0.1Ω / square-2Ω / square according to the thickness.

[0024] Step 3: Use a mask to cover the film, leaving only the evaporated and sputtered metal electrodes on both sid...

Embodiment 2

[0029] A method for preparing a silver nanowire film heater resistant to repeated scratches, comprising the steps of:

[0030] Step 1: Disperse the silver nanowires synthesized by the polyol method in an ethanol solution to obtain a silver nanowire colloid with a concentration of 6.5 mg / mL.

[0031] Step 2: Coating the silver nanowire colloid on the high-temperature-resistant substrate by scraping, spraying, spin coating and other techniques to obtain a silver nanowire film. The high-temperature-resistant substrate is flat or curved glass or ceramics, and the substrate is ultrasonically cleaned in acetone, ethanol, and deionized water for 20-30 minutes in advance. The film is composed of silver nanowire grids to form conductive channels, and the resistance of the silver nanowire film is optional in the range of 0.1Ω / square-2Ω / square according to the thickness.

[0032] Step 3: Use a mask to cover the film, leaving only the evaporated and sputtered metal electrodes on both sid...

Embodiment 3

[0036] A method for preparing a silver nanowire film heater resistant to repeated scratches, comprising the steps of:

[0037] Step 1: Disperse the silver nanowires synthesized by the polyol method in an ethanol solution to obtain a silver nanowire colloid with a concentration of 20 mg / mL.

[0038] Step 2: Coating the silver nanowire colloid on the high-temperature-resistant substrate by scraping, spraying, spin coating and other techniques to obtain a silver nanowire film. The high-temperature-resistant substrate is flat or curved glass or ceramics, and the substrate is ultrasonically cleaned in acetone, ethanol, and deionized water for 20-30 minutes in advance. The film is composed of silver nanowire grids to form conductive channels, and the resistance of the silver nanowire film is optional in the range of 0.1Ω / square-2Ω / square according to the thickness.

[0039] Step 3: Use a mask to cover the film, leaving only the evaporated and sputtered metal electrodes on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com