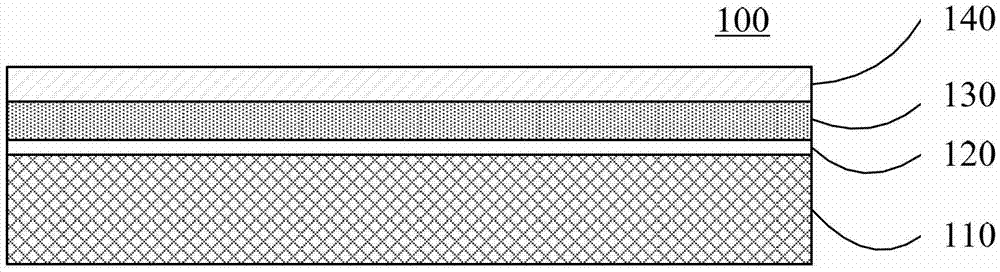

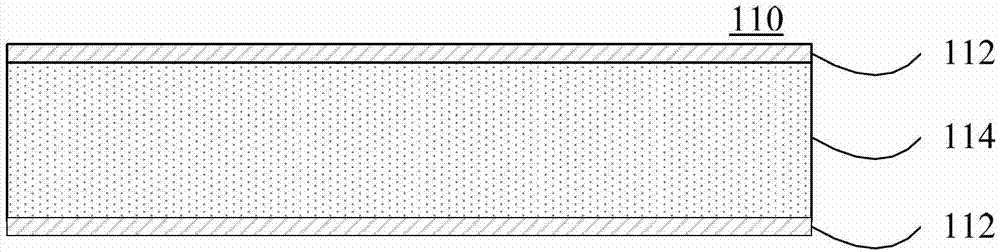

Composite film for touch screen and production method of composite film

A composite film, touch screen technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as low production efficiency, poor adhesion, etc., to improve production efficiency, enhance adhesion, degassing The effect of reducing the requirement of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

Embodiment 2

[0039]

Embodiment 3

[0041]

[0042] The performance of the product is verified by the change rate of the surface resistance of the ITO layer after the composite film for the touch screen is soaked with alkali, and the change rate of the surface resistance is measured within 110%, indicating the adhesion of the ITO layer on the composite substrate good.

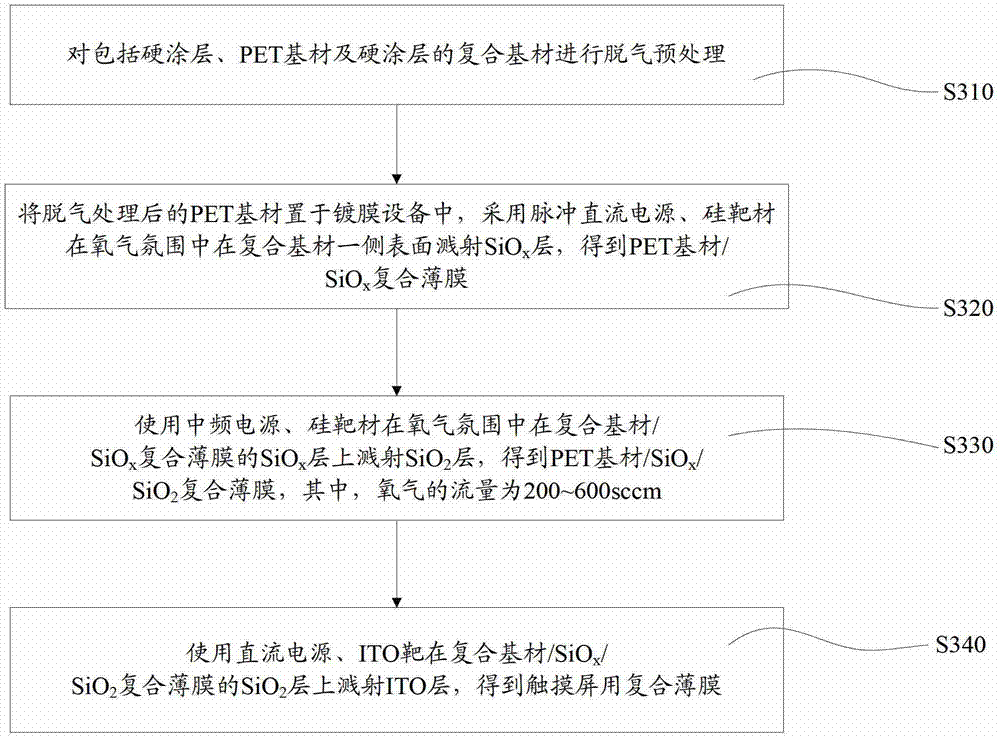

[0043] The manufacturing method of the composite thin film for the touch screen, by adding step S320, that is, adding SiO x layer to ensure the SiO 2 and the adhesion of the ITO layer on the composite substrate, so the requirement for degassing of the composite substrate is greatly reduced, the time for degassing treatment is shortened, and degassing treatment is no longer required before the coating of the main equipment, which greatly improves the use of touch screens. Production efficiency of composite films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com