Attractive-appearance and anti-corrosive polypropylene composite material and preparation method thereof

A technology of composite material and polypropylene, which is applied in the field of good appearance and corrosion-resistant polypropylene composite material and its preparation, can solve the problems of non-alkali resistance, unreported, and cannot be used in the field of long-term contact with liquid environment, etc., to achieve strong tensile strength The effect of strength, excellent comprehensive performance, excellent appearance and chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 The polypropylene composite material of the present invention prepares one

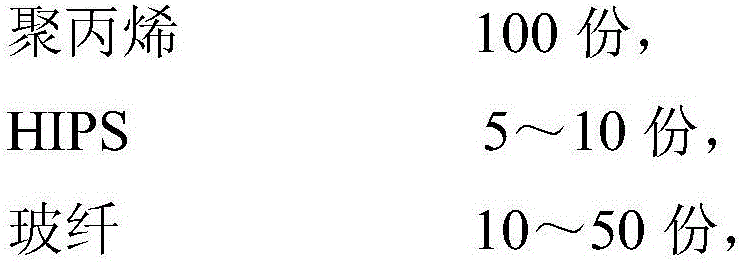

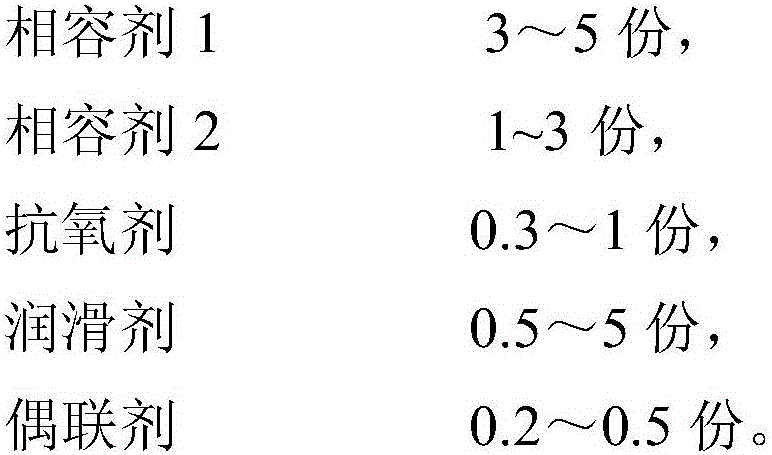

[0031] Take the raw material by the following parts by weight:

[0032]

[0033]

[0034] All raw materials except glass fiber are put into the high mixer and mixed for 3 minutes, and the material is discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate, and the glass fiber port is added when the glass fiber is extruded, and a good product is obtained. Exterior Corrosion resistant polypropylene composite. Wherein, the process temperature is 190° C., and the screw speed is 200 rpm.

Embodiment 2

[0035] Embodiment 2 The polypropylene composite material of the present invention prepares two

[0036] Take the raw material by the following parts by weight:

[0037]

[0038]All raw materials except glass fiber are put into the high mixer and mixed for 6 minutes, and the material is discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate, and the glass fiber port is added when the glass fiber is extruded, and a good product is obtained. Exterior Corrosion resistant polypropylene composite. Wherein, the process temperature is 220° C., and the screw speed is 300 rpm.

Embodiment 3

[0039] Embodiment 3 The polypropylene composite material of the present invention is prepared three

[0040] Take the raw material by the following parts by weight:

[0041]

[0042]

[0043] All raw materials except glass fiber are put into the high mixer and mixed for 8 minutes, and the material is discharged; then the mixed material is put into a twin-screw extruder to extrude and granulate, and the glass fiber port is added when the glass fiber is extruded, and a good product is obtained. Exterior Corrosion resistant polypropylene composite. Wherein, the process temperature is 230° C., and the screw speed is 400 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com