Tracer method based particle concentration measurement system for closed cyclic spray drying system

A drying system and closed cycle technology, applied in the field of physical measurement, to achieve the effect of reducing material sticking to the wall and optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

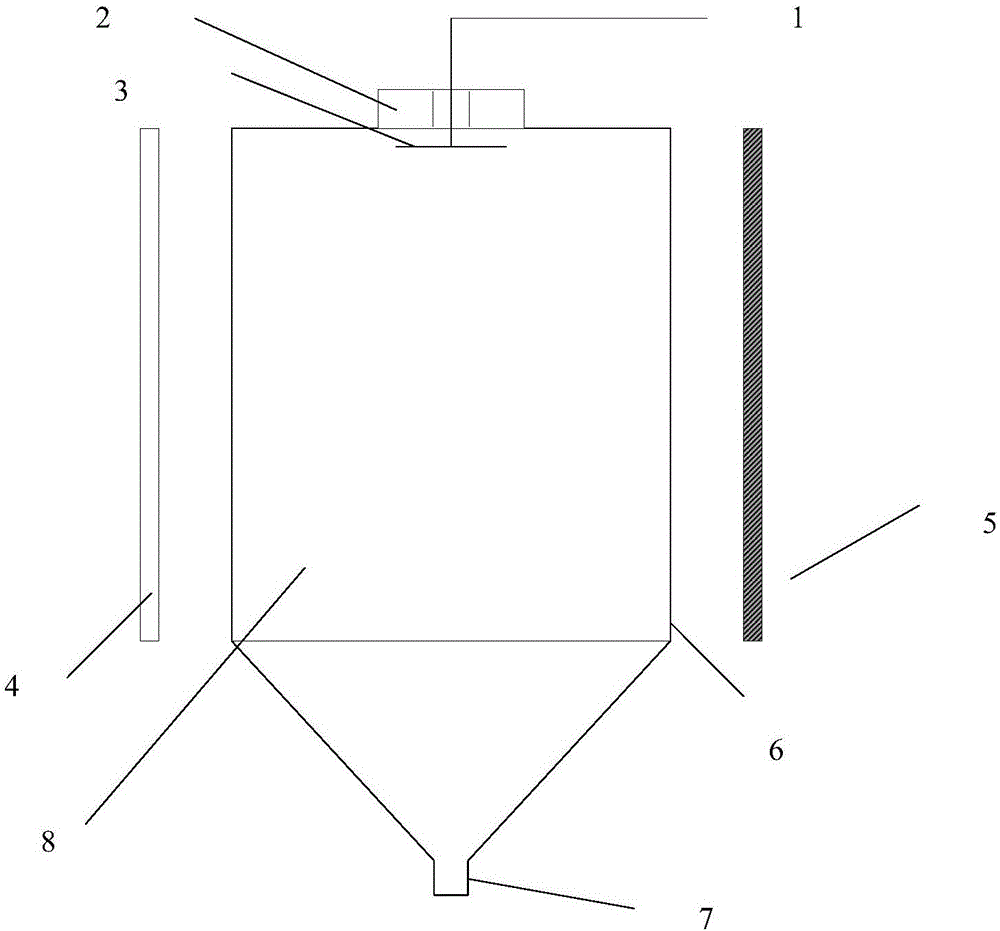

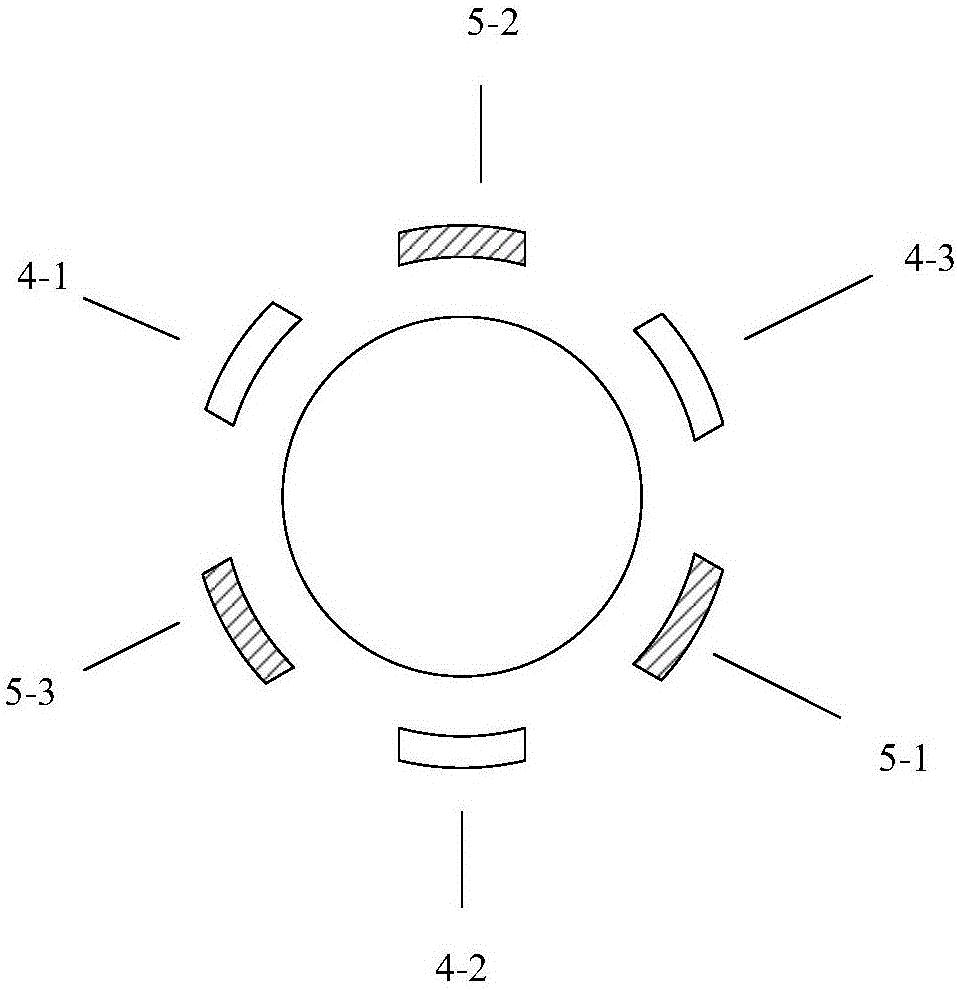

[0018] like figure 1 As shown, the tracer particle concentration measurement system of the closed cycle spray drying system of the present invention includes a laser light source 4, aluminum powder colloid, an image acquisition device 5, a solvent fluid and a spray drying system.

[0019] Specifically, the spray drying system includes a volute hot air distributor 2 , an atomizer 3 , a raw material liquid inlet 1 , a drying chamber 8 , a carrier fluid circulation outlet 6 and a material outlet 7 . The drying chamber 8 is a closed chamber with a cylinder at the top and a cone at the bottom. The heat carrier circulation outlet 6 is arranged on the chamber wall at the bottom of the cylinder, and the material outlet 7 is opened at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com