Automatic dust discharge device of dust collector

An automatic unloading and dust collector technology, applied in the field of dust collectors, can solve the problems of excessive dust accumulation in the ash valve, raising more dust, affecting the service life, etc., to prevent secondary pollution, maintain airtightness, and reduce dust accumulation. sticky wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

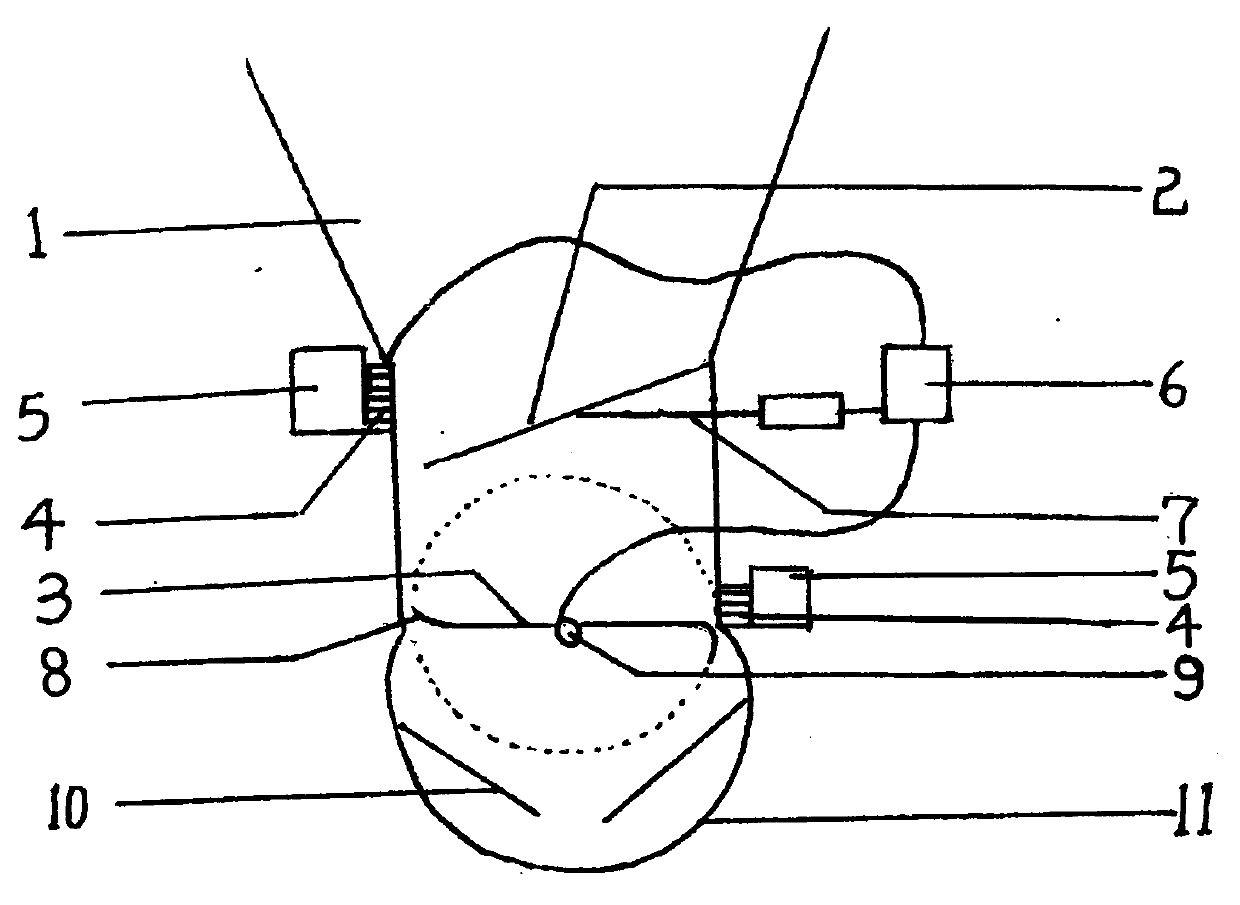

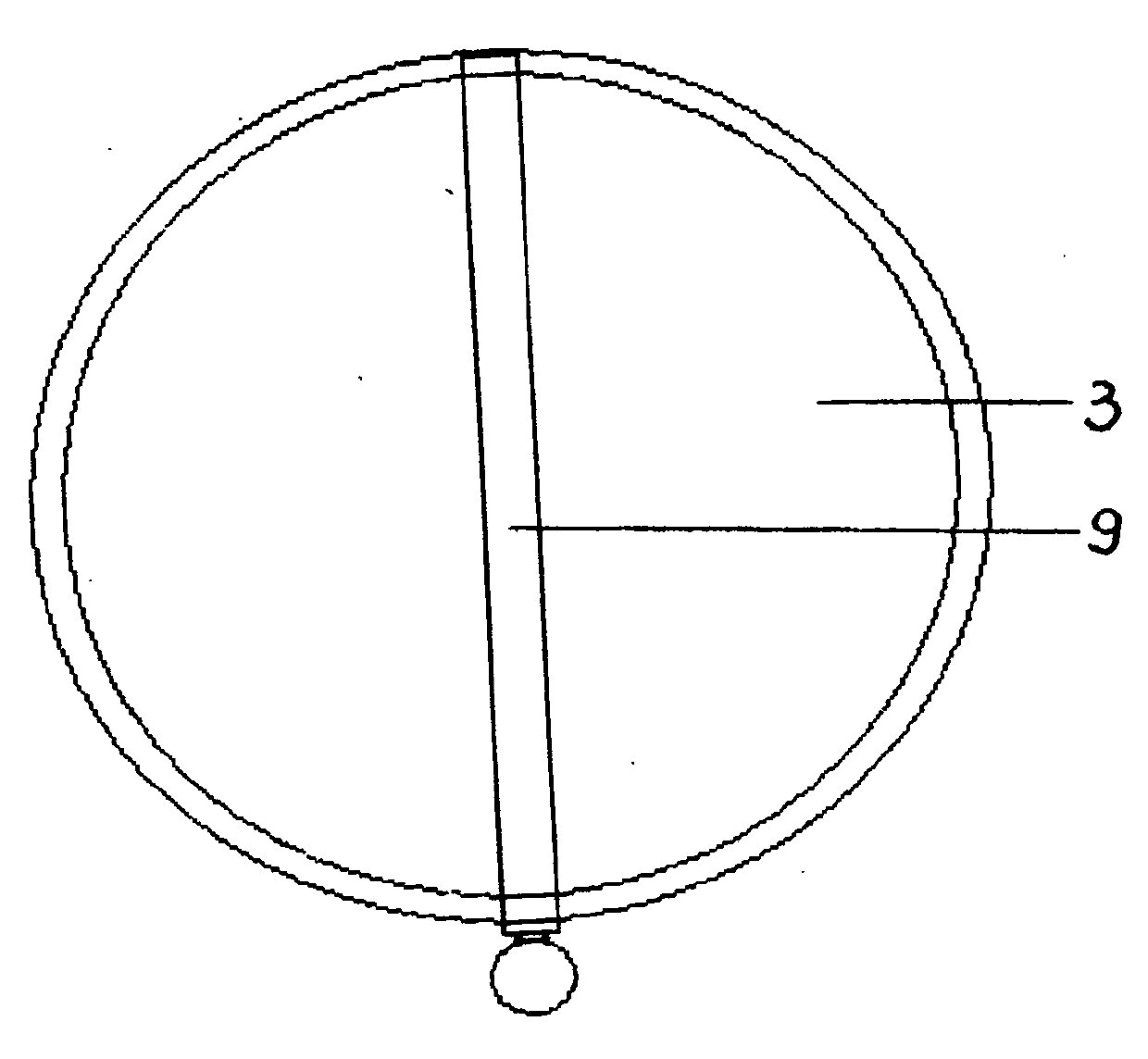

[0009] An automatic ash unloading device for a dust collector, including a lower cone 1, an upper turning plate 2, a rotating plate 3, a weight sensor 4, a signal processing unit 5, a motor 6, an electro-hydraulic push rod 7, a sealing edge 8, and a rotating shaft 9. Ash guide plate 10, ash hopper 11, weight sensor 4, signal processing unit 5, and motor 6 are installed outside the lower cone 1 of the ash unloading device, and upper flap 2 is installed in the lower part of the lower cone 1. The rotating plate 3, the opening and closing of the upper turning plate 2 is controlled by the electro-hydraulic push rod 7 driven by the motor 6, the sealing edge 8 is set on the rotating plate 3 and the rotating shaft 9 is arranged in the middle of the plate, the rotating shaft 9 is connected to the motor 6, and the weight The sensor 4 and the signal processing unit 5 control the start and stop of the motor 6, and the bottom of the ash hopper 11 is a round bottom with an ash guide plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com