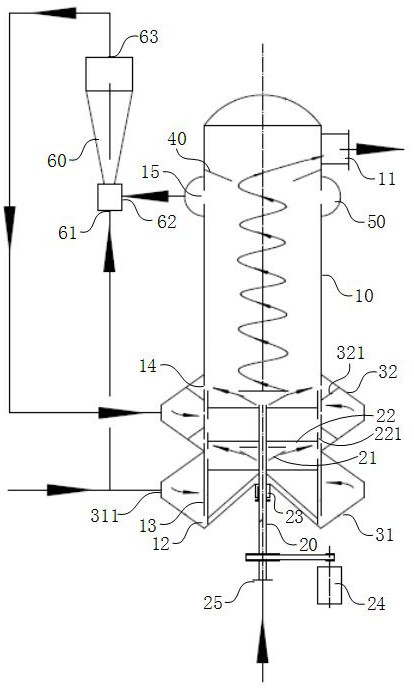

Spin flash dryer

A rotary flash evaporation and drying machine technology, which is applied in the direction of mixers, evaporators, and mixers with rotary stirring devices, can solve the problems of difficult drying of materials, affecting the drying process, and easy agglomeration of materials, so as to improve the drying effect. Reduce material sticking to the wall, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0030] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

[0031] In this document, for the convenience of description, spatially relative terms, such as "below", "below", "lower", "above", "above", "upper", etc., may be used to describe the relationship between one element or feature and another. The relationship of elements or features in the drawings. It will be understood that the spatially relative terms are intended to encompass different orientations of the item in use or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com