Intelligent temperature and humidity control method for closed circulation heat pump tobacco curing barn

A closed-cycle, intelligent control technology, applied in lighting and heating equipment, local agitation dryers, dryers for static materials, etc., can solve the problem that the temperature and humidity cannot meet the needs of tobacco leaf curing at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

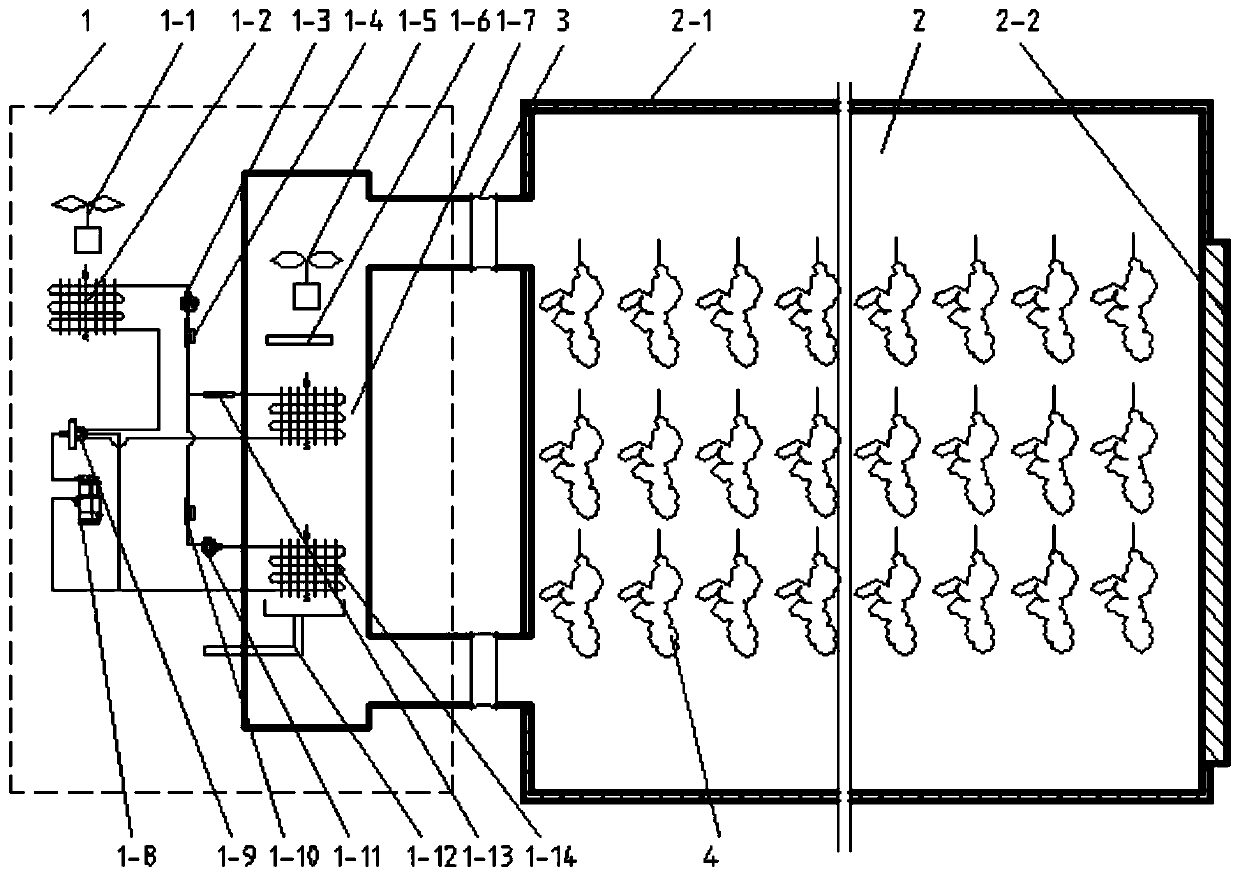

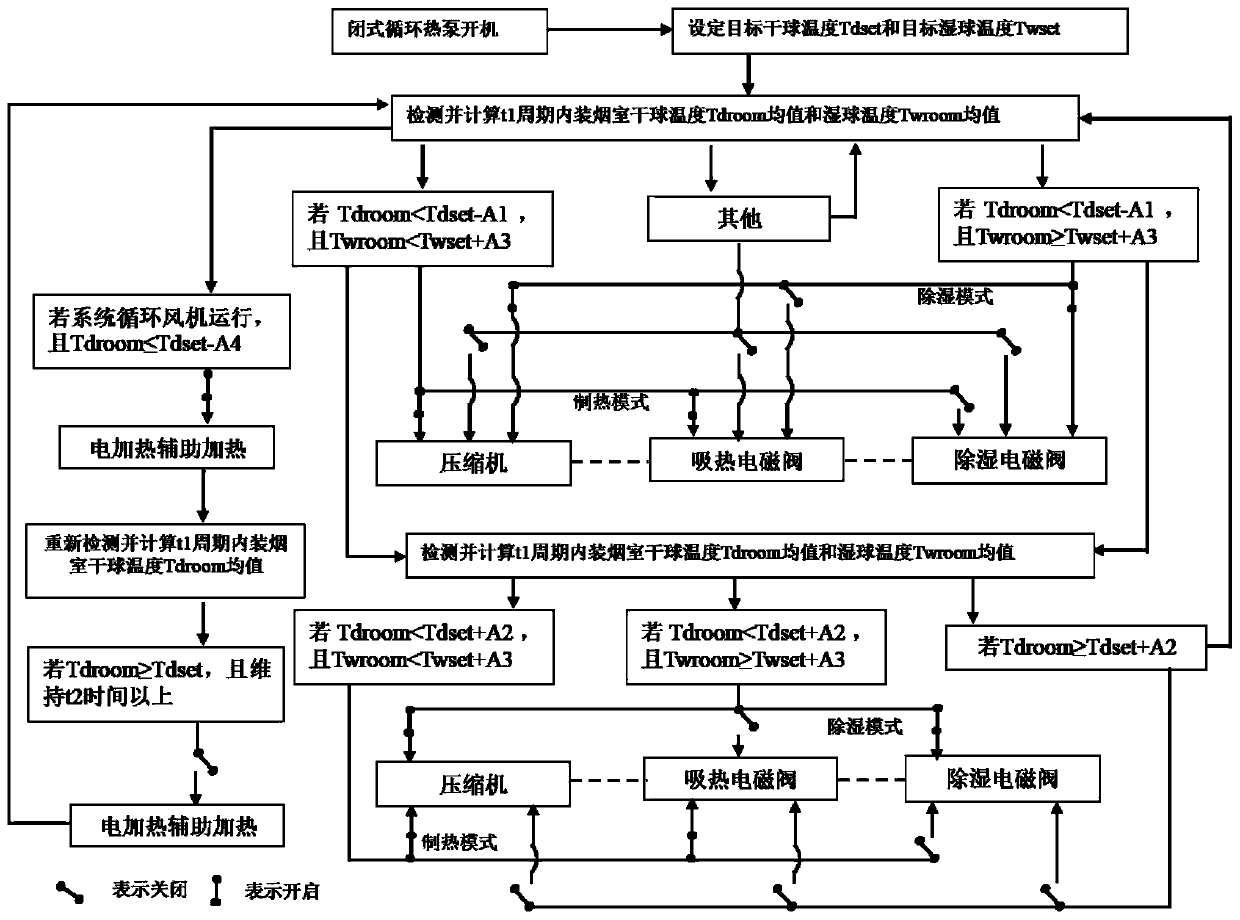

[0038] In order to understand the above-mentioned purposes and advantages of the present invention more clearly, the specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0039] It should be noted that this plan is aimed at the tobacco leaf curing room with closed cycle heat pump. The tobacco leaf curing generally takes 6-8 days, starting from about 30°C and ending at about 68°C. During this process, the temperature of the curing room needs to be controlled. Humidity, so that it is basically consistent with the target temperature and humidity. Different from the heating and dehumidification of the open cycle heat pump, which are carried out independently, the heat pump is only responsible for heating, and the dehumidification depends on the inhalation of fresh air; for the closed cycle heat pump, the heating and dehumidification must be carried out by the heat pump, and there will be temperature and humi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com