Machine room heat removal device for evaporation cooling type heat-pipe heat exchange

A heat pipe heat exchange and evaporative cooling technology, used in household heating, heating methods, household heating and other directions, to achieve the effect of reducing the start-up temperature difference, uniform temperature difference, and good energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

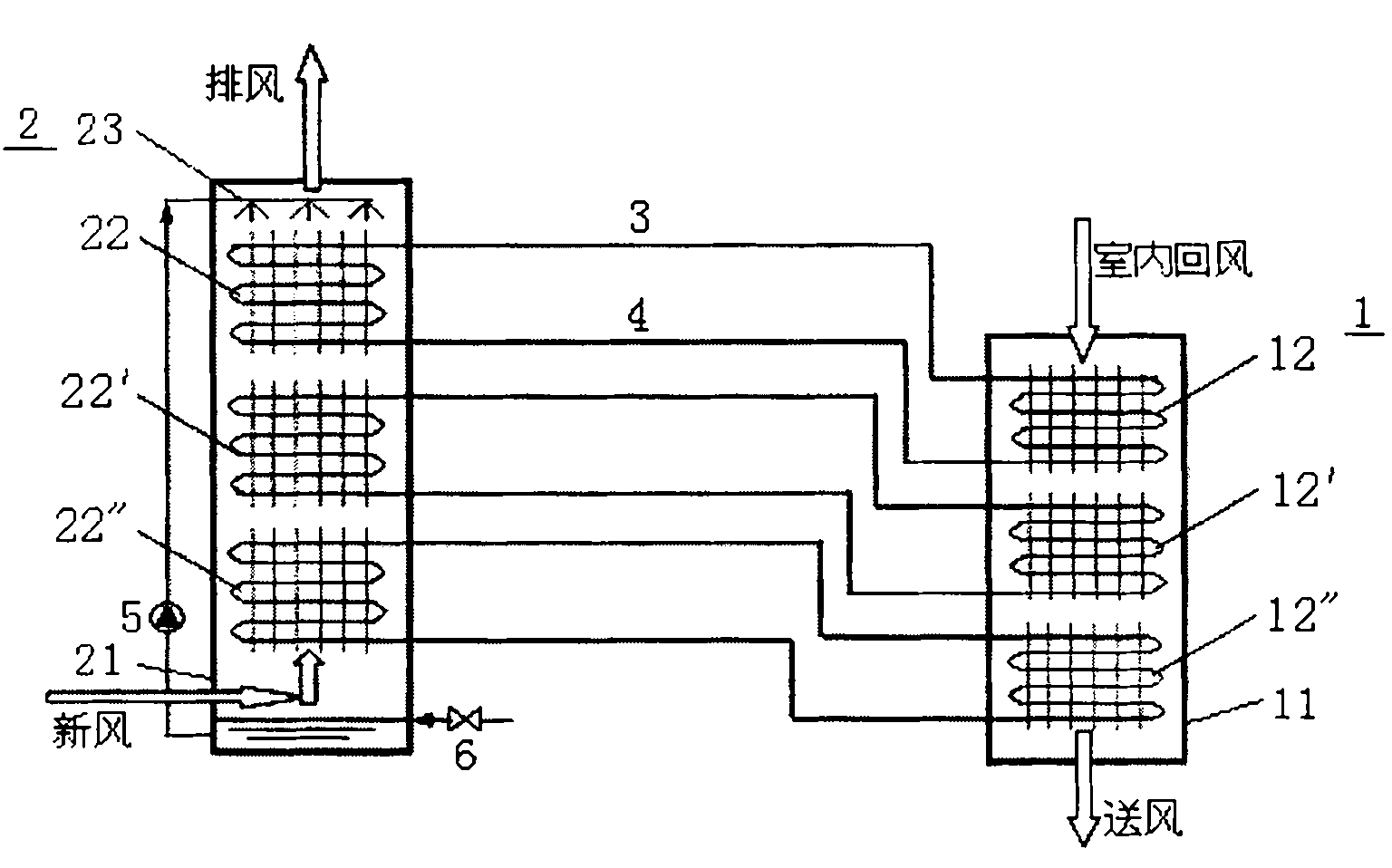

[0017] Such as figure 1 As shown, the heat removal device of this embodiment includes an evaporator 1 installed in the machine room, a water-cooled condenser 2 installed outside the machine room, a gas main pipe 3 and a liquid main pipe 4 . The evaporator 1 includes a box body 11 and three sets of evaporation side heat pipes 12 arranged in the box body; the water-cooled condenser 2 includes a box body 21, three groups of condensation side heat pipes 22 arranged in the box body 21 and a set The spray device 23 on the top of the body 21, and the spray device 23 communicates with the bottom of the box body 21 through a water pump 5 to form a cooling water circulation loop. The outlets of each group of evaporating side heat pipes 12 communicate with the inlets of the corresponding condensing side heat pipes 22 through a gas main pipe 3 respectively, and the outlets of each group of condensing side heat pipes 22 respectively pass through a liquid main pipe 4 and the corresponding e...

Embodiment 2

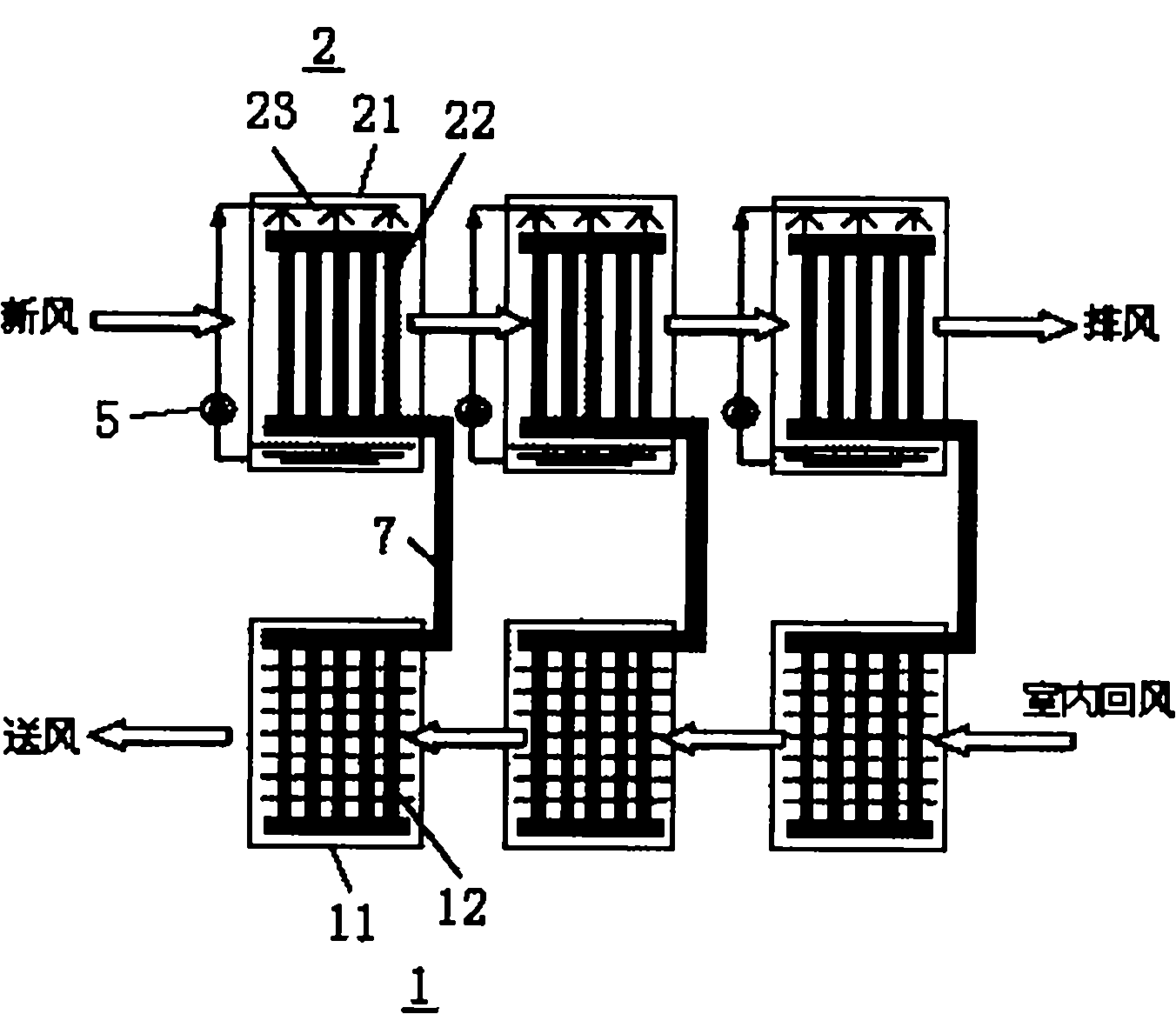

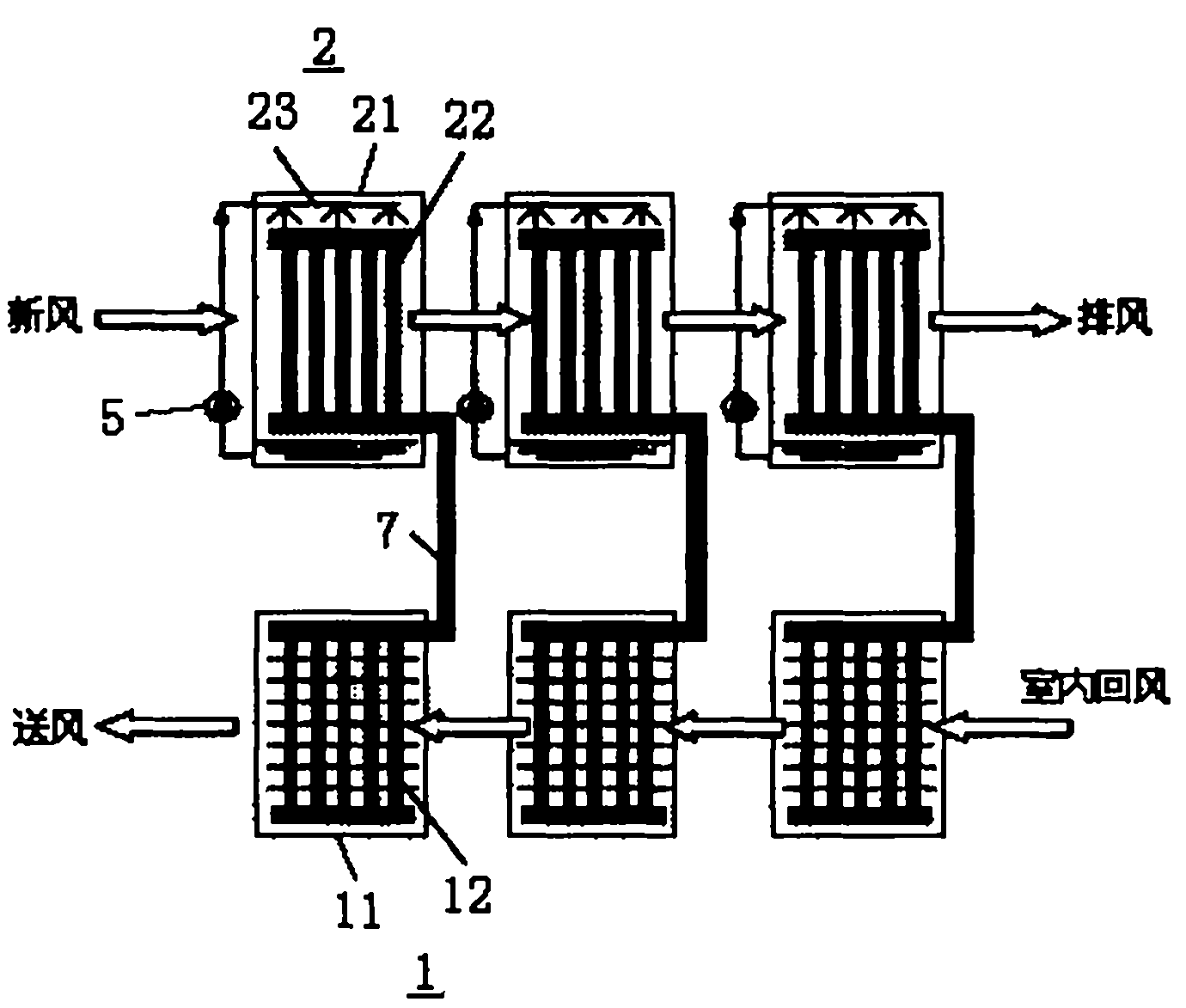

[0025] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is: (1) the bottom of each group of condensation-side heat pipes 22 communicates with the top of the corresponding evaporation-side heat pipes 12 through a gas-liquid main pipe 7, which is simpler in structure; (2) The outdoor water-cooled condenser 2 is an independent water circulation loop. In Embodiment 1, the water-cooled condenser 2 is a unified water circulation loop. When the circulating water volume is relatively small, it cannot ensure that the fins of the heat pipe 22 on the condensation side are fully wetted; when the circulating water volume is too large, each stage of condensation The temperature change of the side heat pipes 22 is relatively small, so that the temperature difference of the refrigerant in each group of condensing side heat pipes 22 is relatively small, resulting in a limited cooling range of the indoor air. This embodiment can avoid the double influence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com