Film pressing wheel

A technology of lamination wheel and tube body, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc. It can solve the problems of affecting the bonding of the film and the circuit board surface, affecting the effect of lamination, and large temperature difference, so as to achieve easy replacement , to avoid sudden rise and fall, the effect of soft temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

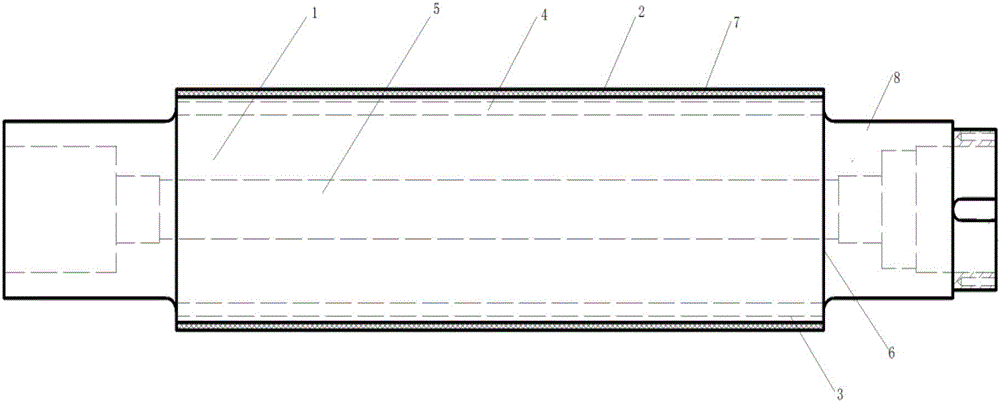

[0028] Such as figure 1 As shown, a laminating wheel provided by the embodiment of the present invention includes a tube body 1, a heat source 5 disposed inside the tube body 1, and a rubber surface 2 wrapped outside the tube body 1 and controlled by a temperature controller electric eye 8; Specifically, the tube wall of the tube body 1 is provided with longitudinal through-holes 3 , and each through-hole 3 is embedded with a longitudinal heat-conducting tube 4 .

[0029] Preferably, after the copper tube is injected with heat-conducting medium liquid water, both ends are sealed, one end is fixed to one end of the tube body by a buckle, and the other end is welded to the other end of the tube body by means of a welding machine.

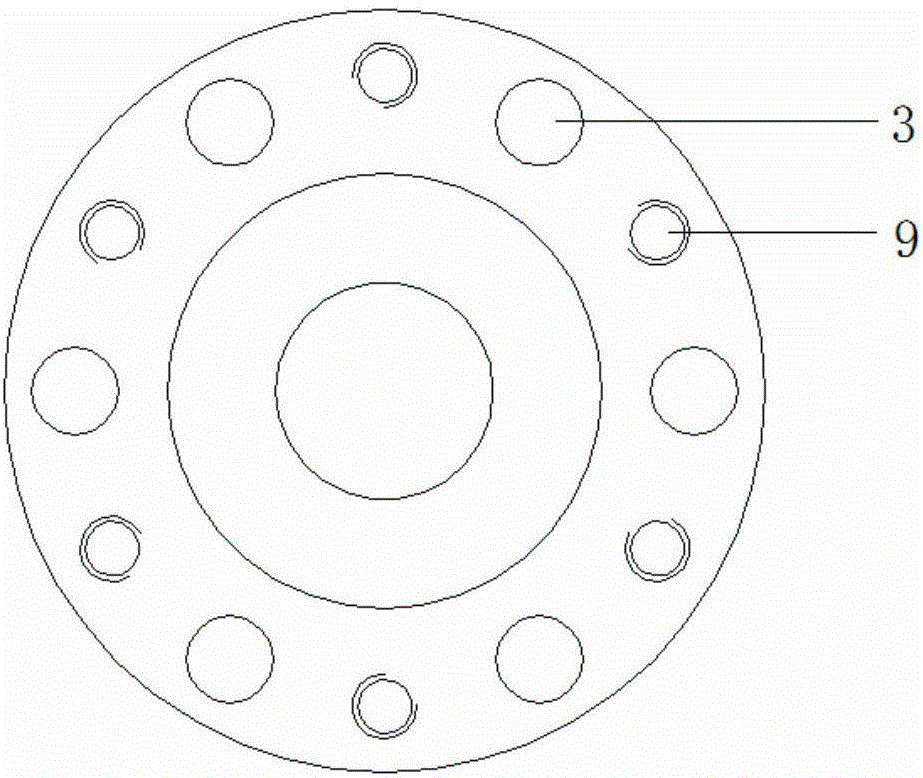

[0030] Such as figure 2 The horizontal surface of the pipe wall of the pipe body 1 shown is provided with 6 screw holes 9, the screw holes 9 are provided with a sealing ring 6, the shaft head 8 and the pipe body 1 are fastened by screws, and the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com