Bending type parallel flow heat exchanger

A parallel flow heat exchanger and parallel flow technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problem that the heat transfer coefficient of the heat exchanger cannot meet the ideal requirements and the heat transfer temperature difference is large , heat transfer coefficient is not high, etc., to achieve the effect of uniform temperature difference, increase heat transfer efficiency, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

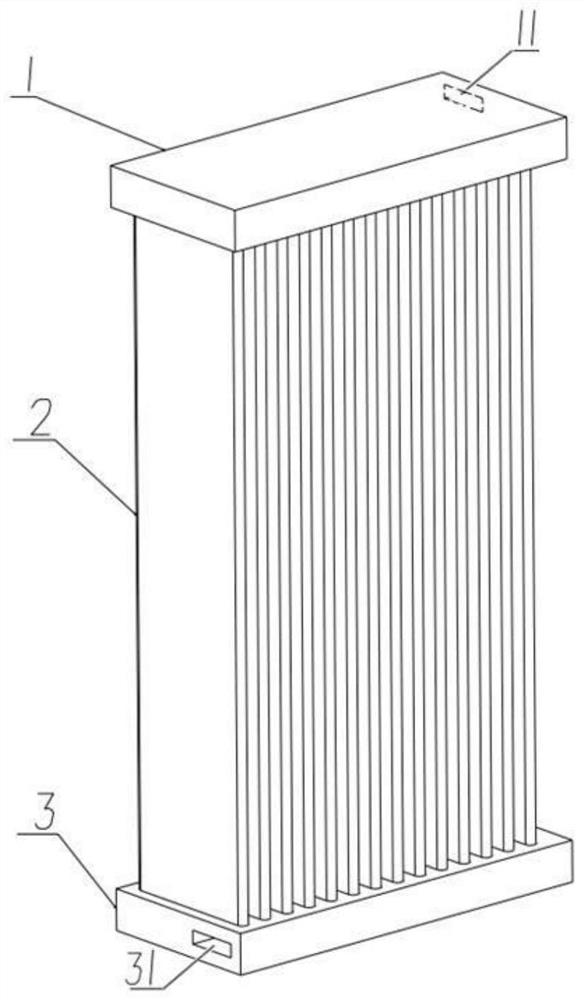

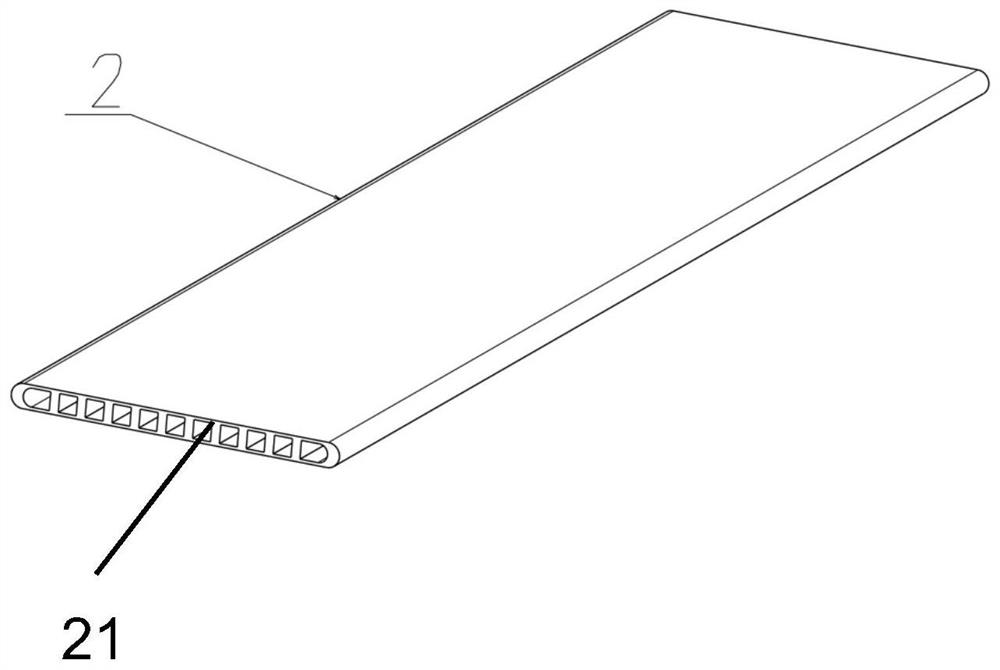

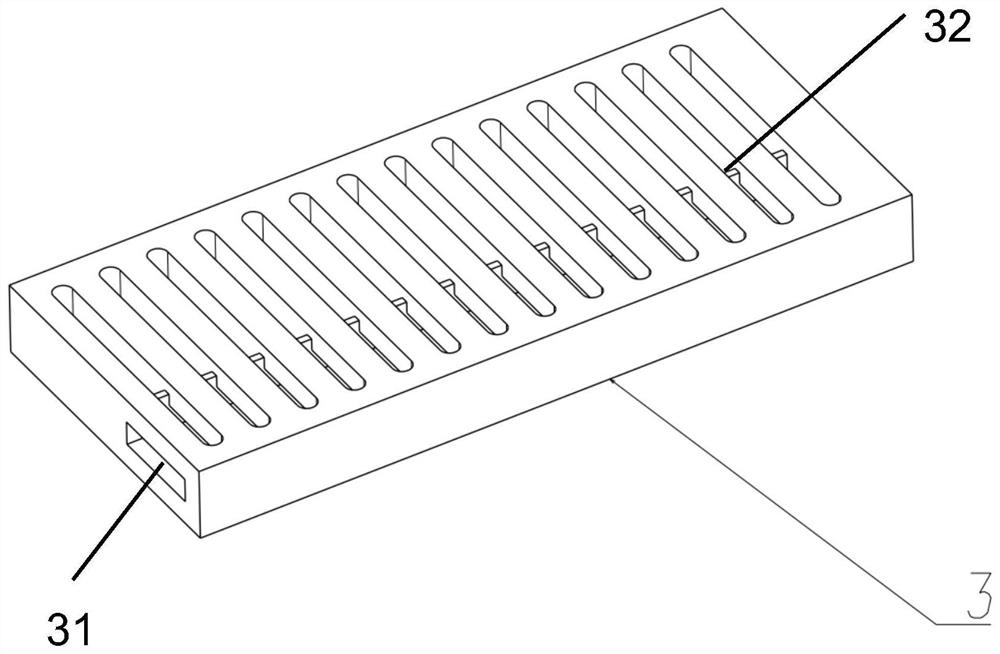

[0018] Such as figure 1 As shown, a bent parallel flow heat exchanger includes an upper end plate 1 and a lower end plate 3, a plurality of parallel flat tubes 2 are fixed between the upper end plate 1 and the lower end plate 3, and a plurality of flat tubes 2 are arranged inside the flat tubes 2. Parallel parallel flow channels 21, the upper end plate 1 is provided with a refrigerant inlet 11 and an upper drainage groove (not shown in the figure), and the lower end plate 3 is provided with a refrigerant outlet 31 and a lower drainage groove 32, and the refrigerant passes through the upper end plate The refrigerant inlet 11 of 1 enters the upper drainage groove, flows into the flat tube 2, passes through the parallel flow channel 21 in the flat tube 2, reaches the lower drainage groove 32 at the lower end plate 3, and then enters the flat tube 2 and flows into the upper end plate 1 to reach the upper end The upper drainage groove of the plate 1 changes direction and then enter...

Embodiment 2

[0022] Such as Figure 6 , a bent parallel flow heat exchanger, comprising an upper end plate 1 and a lower end plate 3, a plurality of flat tubes 2 arranged in parallel are fixed between the upper end plate 1 and the lower end plate 3, and S-shaped flow channels are arranged in the flat tubes 2 21. The lower end of the flat tube 2 is provided with a refrigerant inlet pipe 5, and the upper end of the flat pipe 2 is provided with a refrigerant outlet pipe 4. Both the refrigerant inlet pipe 5 and the refrigerant outlet pipe 4 are provided with a plurality of square holes 6, and the refrigerant inlet Each square hole 6 on the tube 5 corresponds to the refrigerant inlet 23 on each flat tube 2 , and each square hole 6 on the refrigerant outlet pipe 4 corresponds to the refrigerant outlet 23 on each flat tube 2 .

[0023] The upper end plate 1 and the lower end plate 3 of the heat exchanger play the role of installing and fixing the flat tube 2; the flow channel type in the flat tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com