Square porous ceramic vertical tube type dew point indirect evaporative cooler

An evaporative cooler and porous ceramic technology, applied in the field of air conditioning and refrigeration, can solve the problems of low humidity, increased energy consumption of heat exchangers, and heavy maintenance workload, achieving high heat and moisture exchange efficiency, obvious energy-saving advantages, and extended The effect of exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

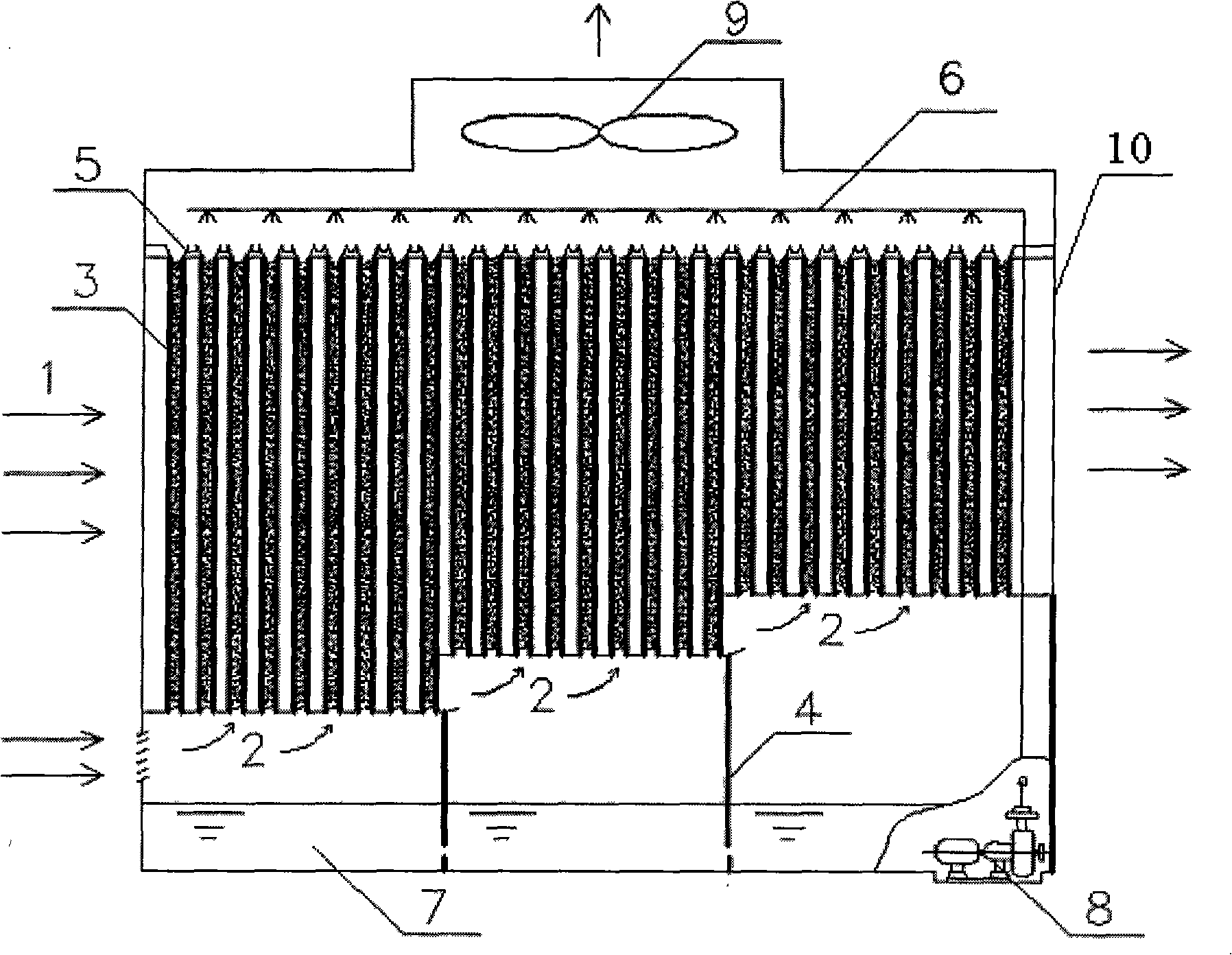

[0023] figure 1 What is shown is an embodiment of a square porous ceramic standpipe dew point indirect evaporative cooler provided by the present invention. In the cooler housing 10, the cooler core, the water distribution device on the upper part of the cooler core, the blower fan 9, and the water reservoir 7 and the water pump 8 on the lower part of the cooler core are set.

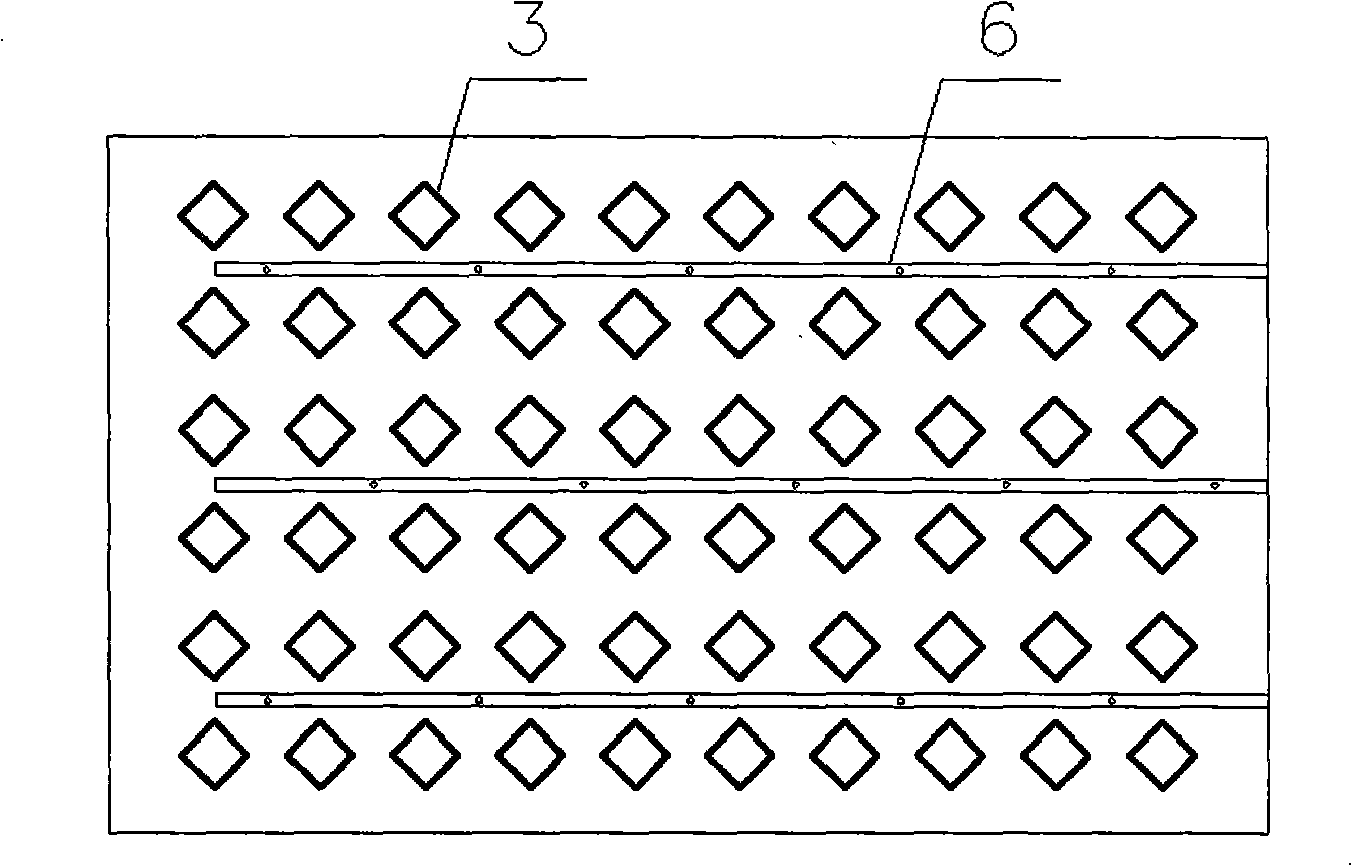

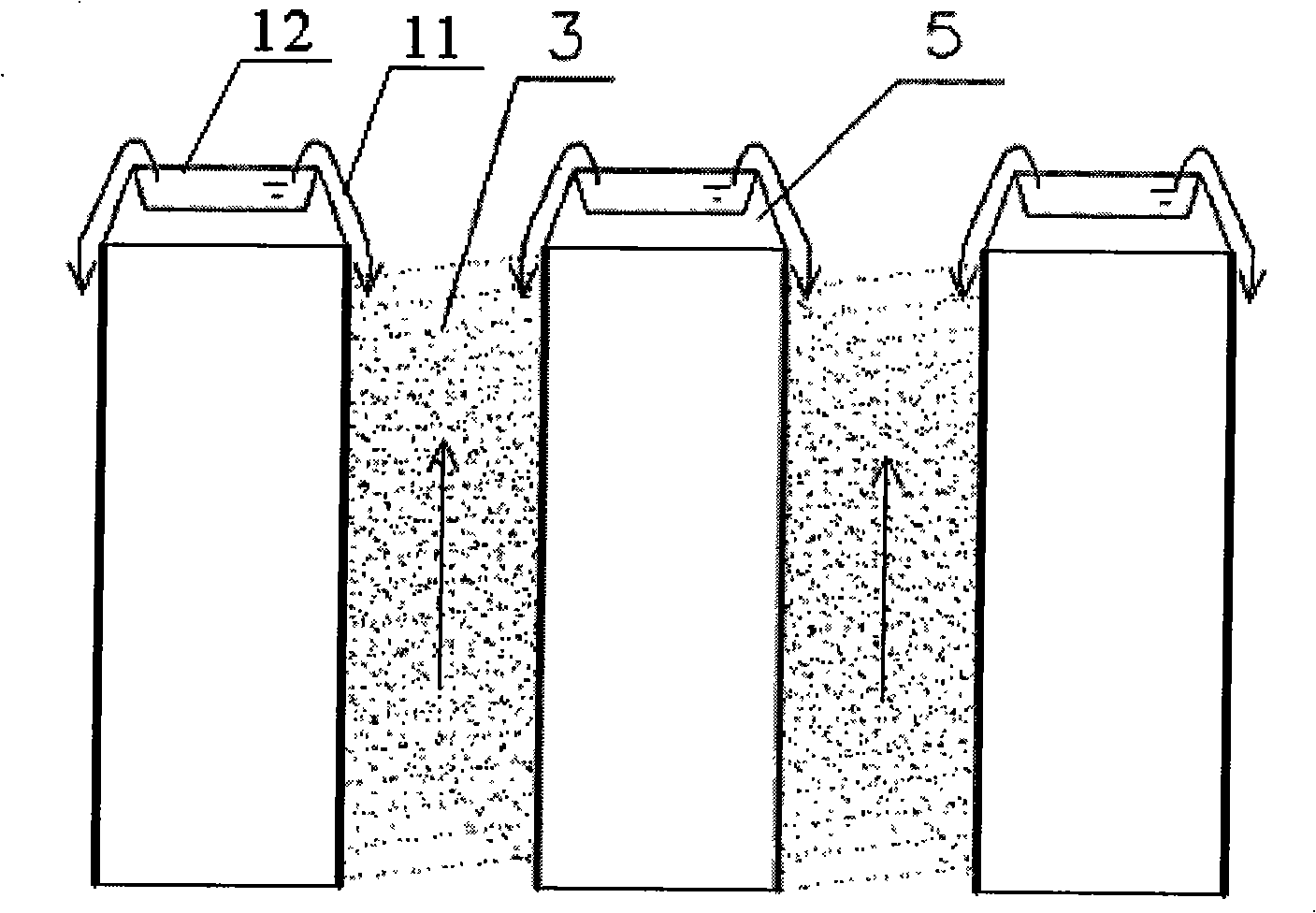

[0024] The core of the cooler, the heat exchange tubes 3 are arranged vertically and in parallel to form a matrix form of multiple rows and columns. The heat exchange tubes 3 are made of porous ceramic materials, and the outside of the tubes is covered with a film made of the same material. The combination of the two up to avoid moisture penetration. The cross section of the heat exchange tube 3 is square, so that the diagonal direction of the square tube cross secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com