Night sky cooling system

a cooling system and night sky technology, applied in the field of cooling system, can solve the problems of large electricity consumption, complex systems, and high cost, and achieve the effects of reducing energy consumption, reducing energy consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

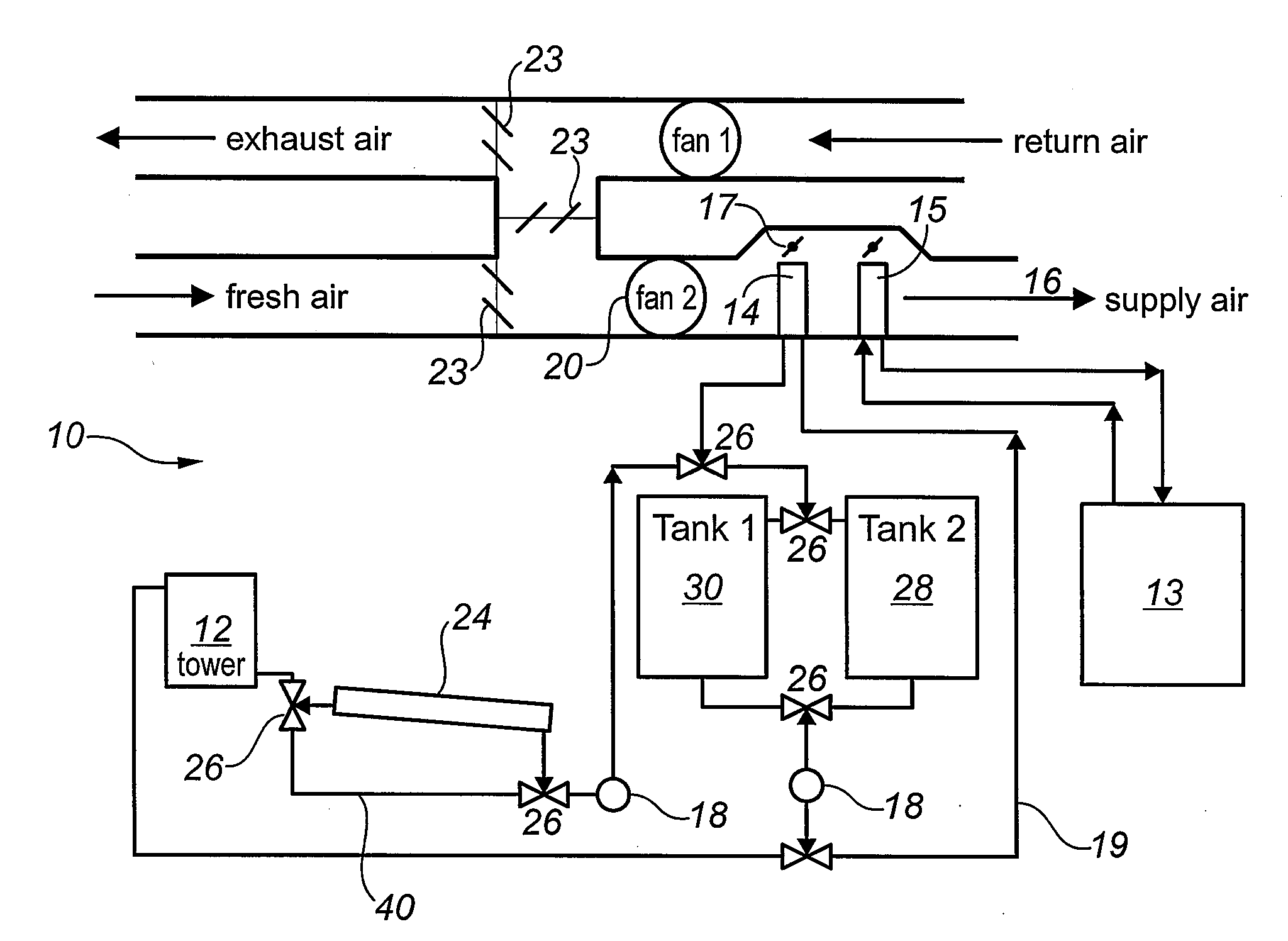

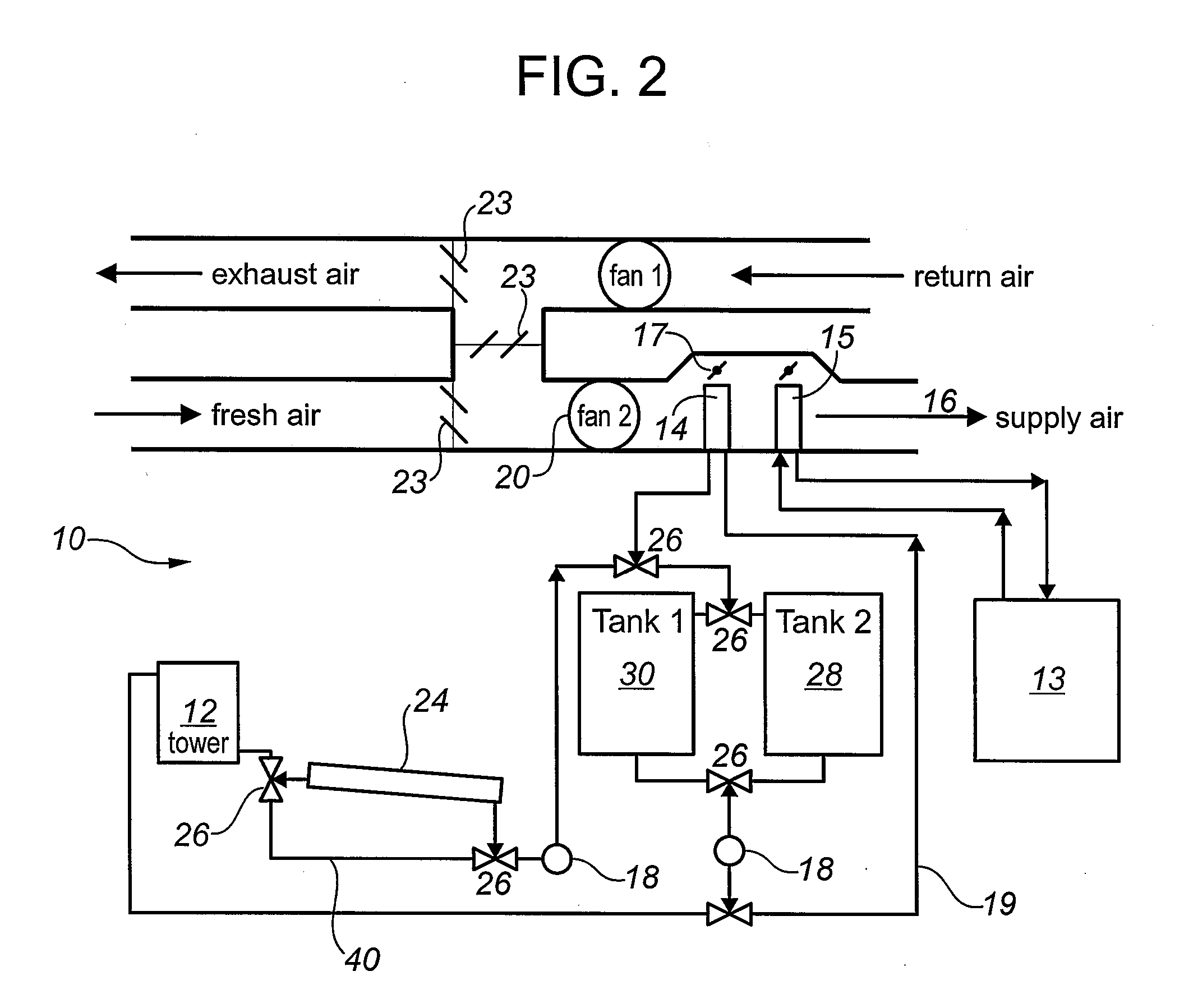

[0073]Operation of the system as depicted in FIG. 3 having a single cooling tower (12), a night sky cooler (24), two storage tanks (28,30) and a single heat exchange element (14).

[0074]The sequence of operation at night for night time cooling and storage is as follows. Assuming that the first tank (30) is full of spent (warn) water, the cooling tower (12) is activated and valve V4 is opened to allow the flow of water from tank (30) to pump P2. Pump P2 is started and valve V3 is opened to allow the flow of water to the cooling tower (12) where water is cooled. Valve V1 is closed to allow the flow of water from the cooling tower (12) to the night sky cooler (24). Further cooling is achieved in the night sky cooler (24) by means of heat radiation to space. Valve V2 is opened to allow night sky cooler (24) discharge to flow to pump P1. Valve V7 is opened to allow flow to valve V5 and to the second tank (28), being the empty tank in this case which will be used to store the cooled water ...

example 2

[0076]Operation of the system as depicted in FIG. 5 having a cooling tower (12), a night sky cooler (24), two storage tanks (28,30) and a single heat exchange element (14) and a second evaporative cooling system (60).

[0077]The sequence of operation for night cooling and storage is as follows. Assuming that the first tank (30) is full of spent (warm) water, the cooling tower (12) is activated and valve V4 is opened to allow the flow of water from the first tank (30) to pump P2. Pump P2 and pump P3 are started and valve V3 is opened to allow the flow of water to the primary cooling tower (12) where water is cooled. The air supply to the primary cooling tower (12) is pre-cooled by the second evaporative cooling system (60). Discharge from the cooling tower (12) flows to valve V1 which is closed to allow flow to the night sky cooler (24) and further cooling of the water is achieved through heat radiation to space. Valve V2 is opened to allow discharge from the night sky cooler (24) to f...

example 3

[0079]Operation of the system as depicted in FIG. 7 having a cooling tower (12), a night sky cooler (24), two storage tanks (28,30) and a single heat exchange element (14) and a second (60) and third (70) evaporative cooling system.

[0080]The sequence of operation for night cooling and storage is as follows. Assuming that the first tank (30) is full of spent (warm) water, then the cooling tower (12) is activated and valve V4 is opened to allow flow from the first tank (30) to pump P2. Pump P2 is started and valve V3 is opened to allow the flow of water to the primary cooling tower (12) where water is cooled. Discharge from the cooling tower (12) flows to valve V1 which is closed to allow the flow of water to the night sky cooler (24) where further cooling is achieved by radiation to space. Valve V2 is opened to allow the flow of water from the night sky cooler (24) to pump P1. Pump P1 is activated with valve V7 opened to direct flow to valve V5. Valve V5 is opened to allow flow into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com