Self-adapting energy saving control device with variable flux for compression type central conditioner

A central air-conditioning and energy-saving control technology, applied in heating and ventilation control systems, applications, heating methods, etc., can solve the problem of small temperature difference between chilled water supply and return water, small temperature difference between cooling water inlet and outlet, and large chilled water supply flow and cooling water inlet flow. , the maximum cooling load design allowance is large, etc., to achieve the effect of enhancing safety, prolonging equipment life, and reducing operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

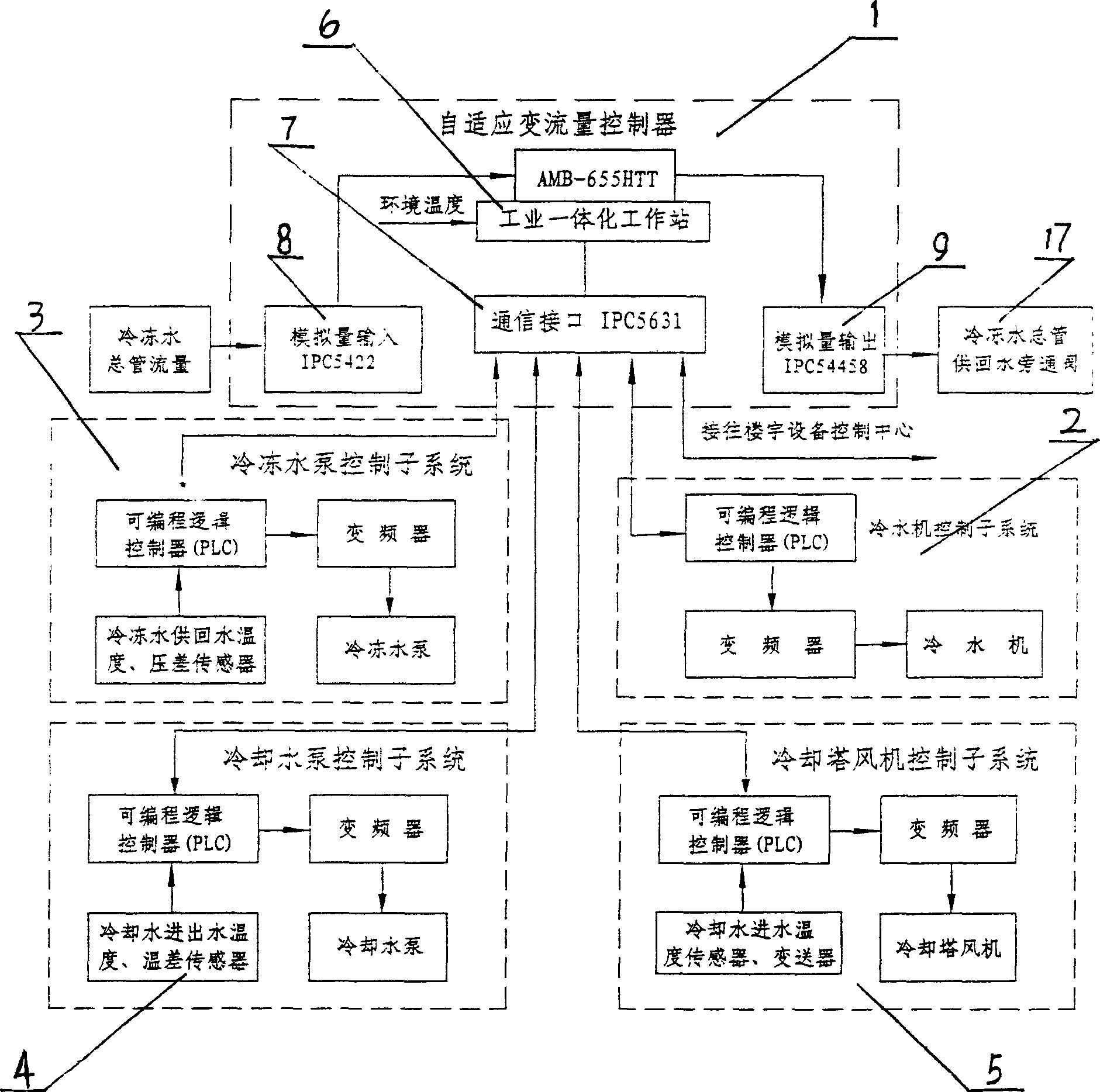

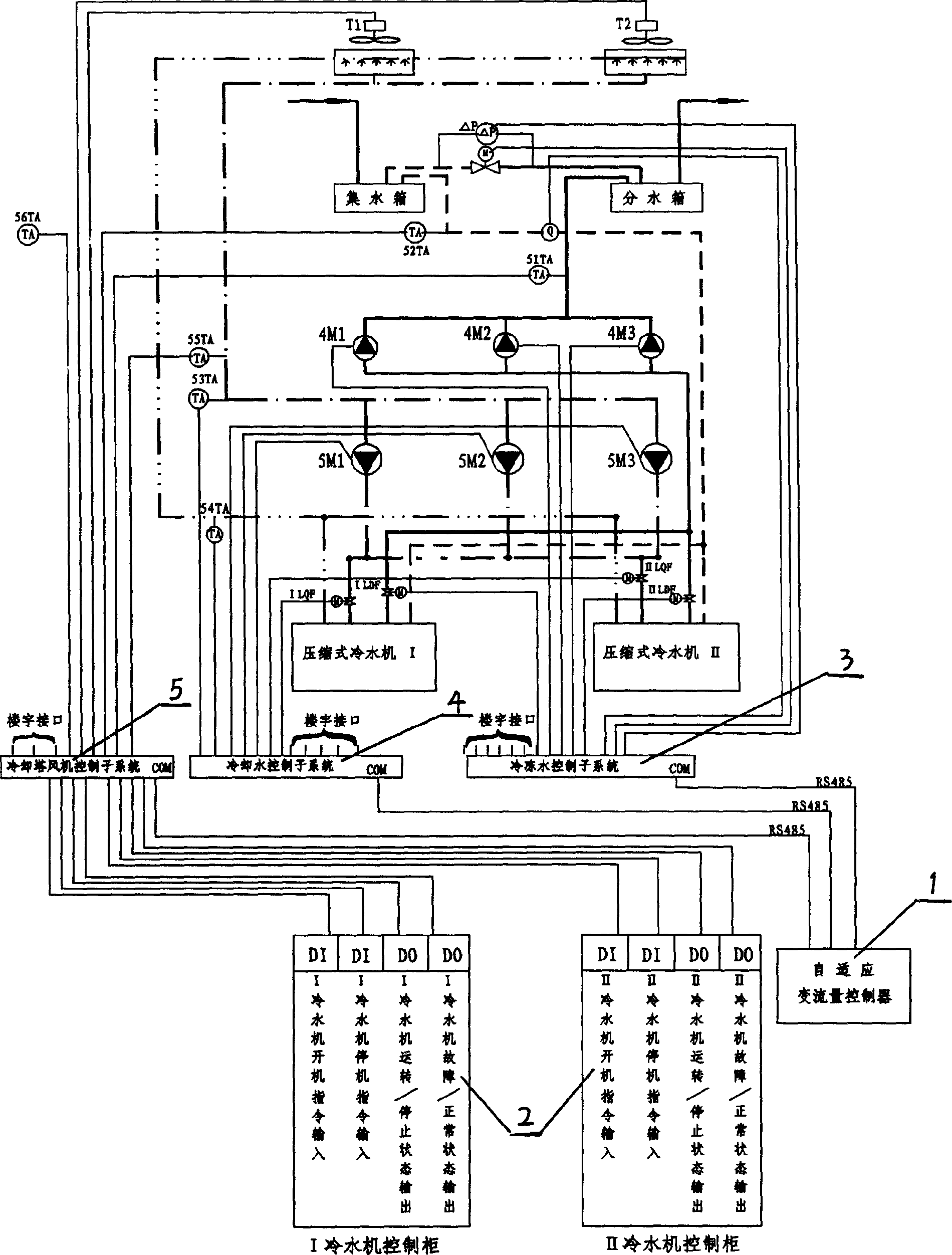

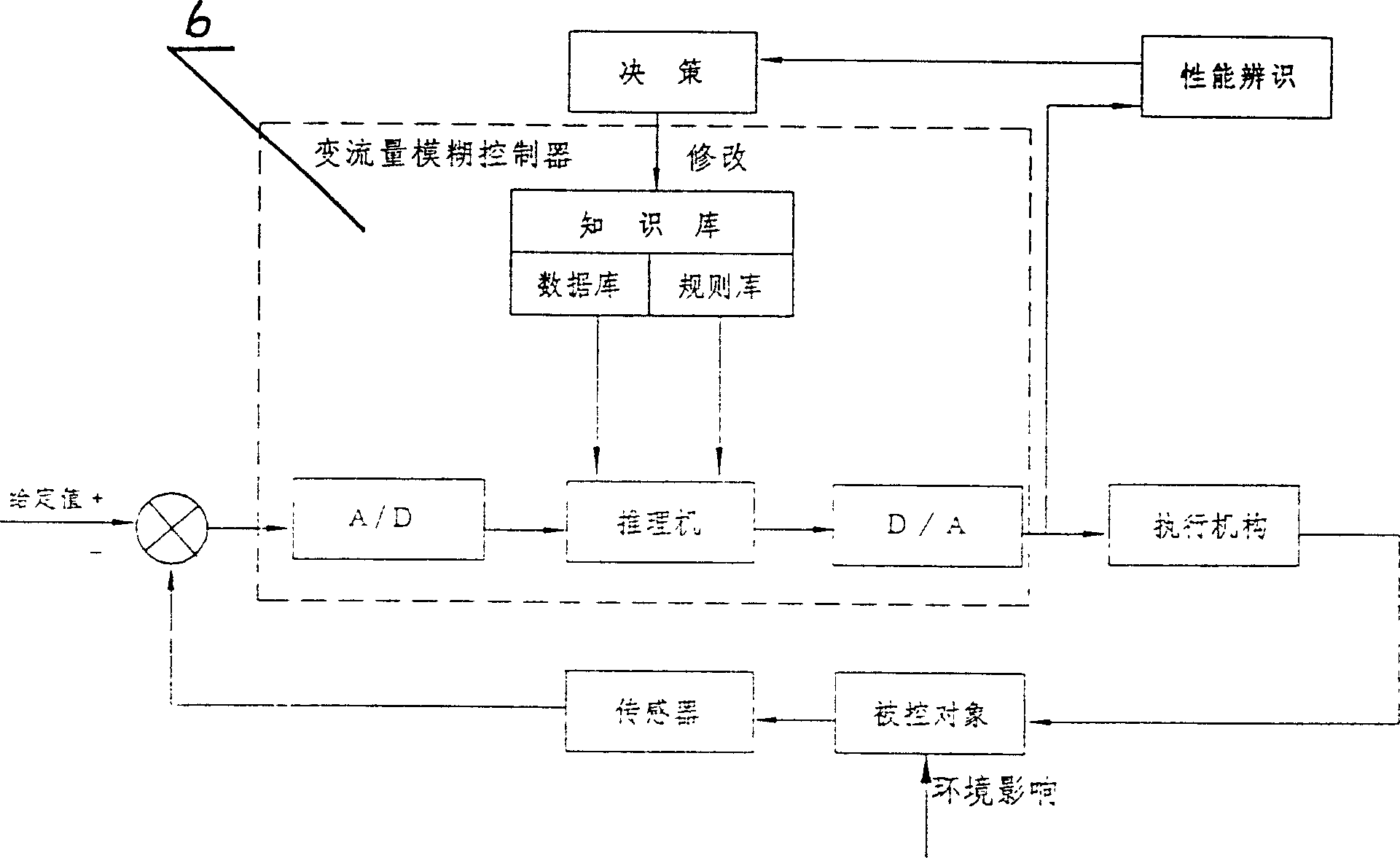

[0014] Embodiment of the present invention: the adaptive variable flow controller (1) connects the chiller control subsystem (2), the chilled water pump control subsystem (3), and the cooling water pump control subsystem ( 4) and the cooling tower fan control subsystem (5), wherein the adaptive variable flow controller (1) consists of an industrial integration workstation (AMB-655HTT) (6), a communication interface (IPC5631) (7), an analog input Card (IPC5422) (8), analog output card (IPC5445B) (9). By detecting the chilled water supply and return water temperature, pressure difference and chilled water main pipe flow, these test data are sent to the programmable logic controller and adaptive variable flow controller (1), and the chilled water pump is adjusted through adaptive fuzzy calculation and control Rotational speed, the opening degree of the bypass valve (17) of the chilled water main pipe supply and return; by detecting the temperature and temperature difference betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com