Light bidirectional stacking carrier

A stacker, light technology, applied in the direction of the lifting device, etc., can solve the problems that affect the service life of the forklift, the safety of the forklift, the large current of the controller, and the low efficiency, so as to improve the economy and usability, reduce the model and power, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

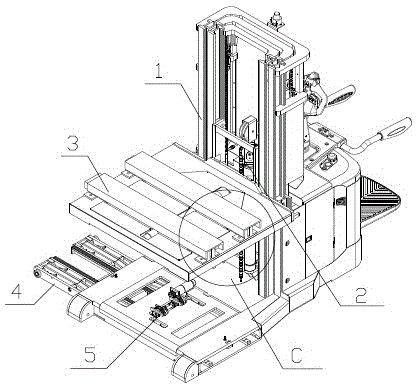

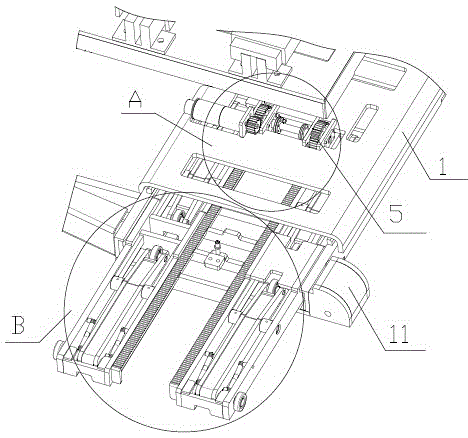

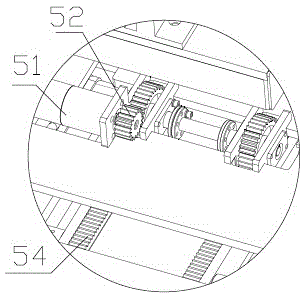

[0045] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown: a lateral forklift, including a car body 1, a fork body 3 installed on the car body 1 and a lifting device 2 for lifting the fork body 3 on the car body 1, and the fork body 3 moves laterally; The lateral forklift also includes a load-bearing device 4 for stabilizing the center of gravity of the vehicle body 1 when the fork body 3 picks up objects laterally on the vehicle body 1 and a drive device 5 for driving the load-bearing device 4 to move.

[0046] The vehicle body 1 is provided with a cockpit, and the user sits in the cockpit to drive the vehicle body. The lifting device 2 connects the vehicle body 1 and the fork body 3. Various solutions in the known technology can be used, such as the combination of chains and gears or hydraulic pressure. Lifting rod, adjust the lifting device 2 after the fork body 3 fixes the goods, so that the fork body 3 and the goods are raised, which i...

Embodiment 2

[0053] Embodiment 2: The difference from Embodiment 1 is the difference of the driving device 5. The driver is an oil cylinder and a piston rod. The oil cylinder body is arranged on the car body 1, and the piston rod is connected with the load-bearing device 4 to push the load-bearing device 4 to move on the guide rail. .

Embodiment 3

[0054] Embodiment 3: The difference from Embodiment 1 is the difference of the stabilizing device 7, which includes a telescopic support rod, one end of which is connected to the inner connecting plate 42, and the other end is connected to the outer guide plate 41. The inner connecting plate 42 and the outer guide plate 41 can be at the same height when the load-bearing device 4 is not in working condition, and the load-bearing wheels 43 have a certain height from the ground and do not conflict with the ground; , the inner connecting plate 42 descends, the load-bearing wheels 43 collide with the ground, and the support rod locks its own length immediately, thereby resisting the load-bearing wheels 43, preventing the load-bearing wheels 43 from resetting after being pressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com