Ultrasonic wave stirrer

An ultrasonic and agitator technology, applied in the field of ultrasonic agitator, can solve the problems of increasing the frequency and speed of material molecular motion, increasing the penetrating power of solvents, and waste of resources, etc., to achieve enhanced mixing effects, reduced equipment models, and fast fusion speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

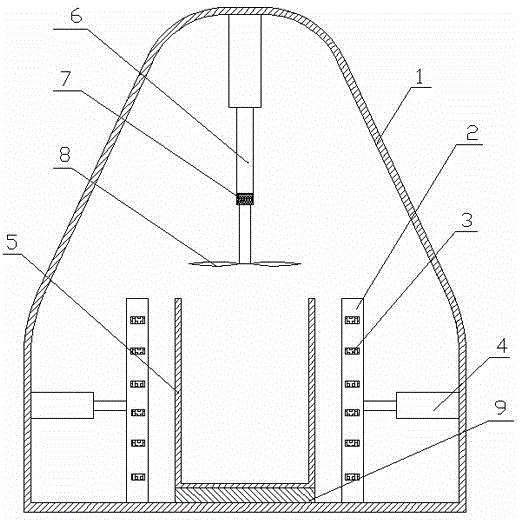

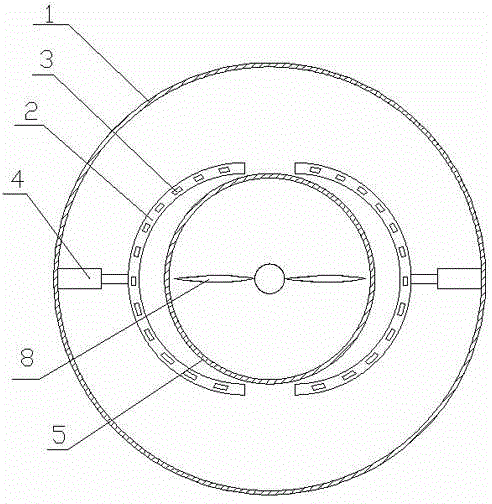

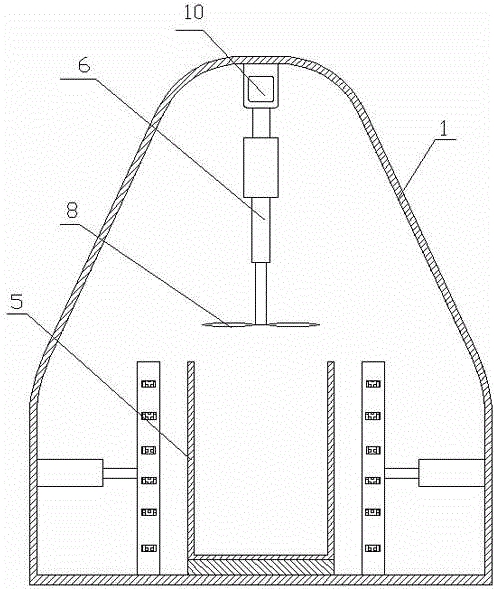

[0018] Such as figure 1 As shown, an ultrasonic mixer includes a housing 1 and a mixing bucket 5 provided inside the housing 1. The mixing bucket 5 is arranged on a circular positioning piece 9 located on the inner bottom of the housing 1. The radius of the positioning piece 9 is The same as the radius of the mixing bucket 5, the positioning piece 9 positions the mixing bucket 5 so that it and the mixing bucket 5 become an integral structure, and also includes an ultrasonic generating mechanism for wrapping the outer wall of the mixing bucket 5, and the ultrasonic generating mechanism includes tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com