Device for automatically adjusting oil discharge capacity of lifting system

An automatic adjustment and capacity technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to operate continuously online, lack of safety and controllability of anti-aircraft shells, inconvenient operation of pressure sensors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] The invention relates to a device capable of automatically adjusting the oil discharge capacity of a lifting system, through which the oil discharge capacity of the lifting system can be automatically adjusted, so as to achieve energy saving, reduce equipment wear and improve production efficiency.

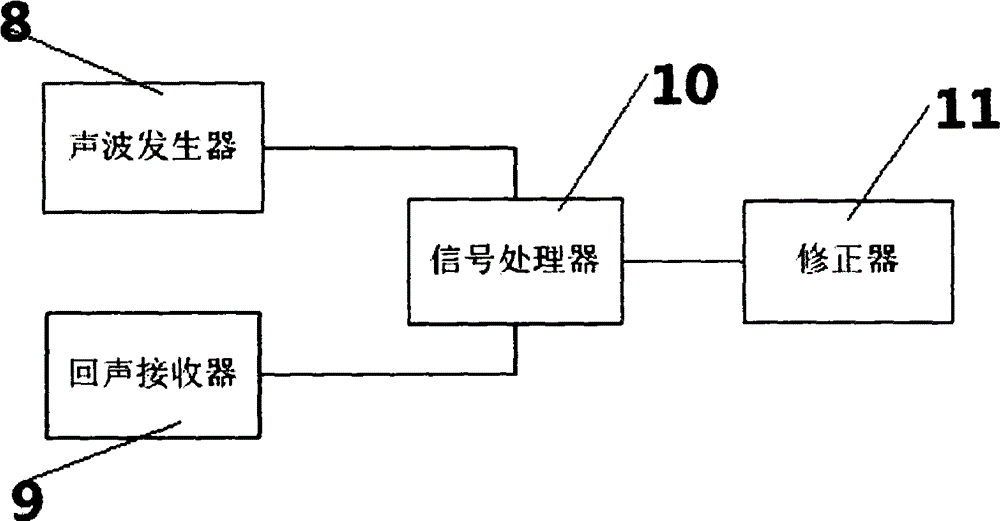

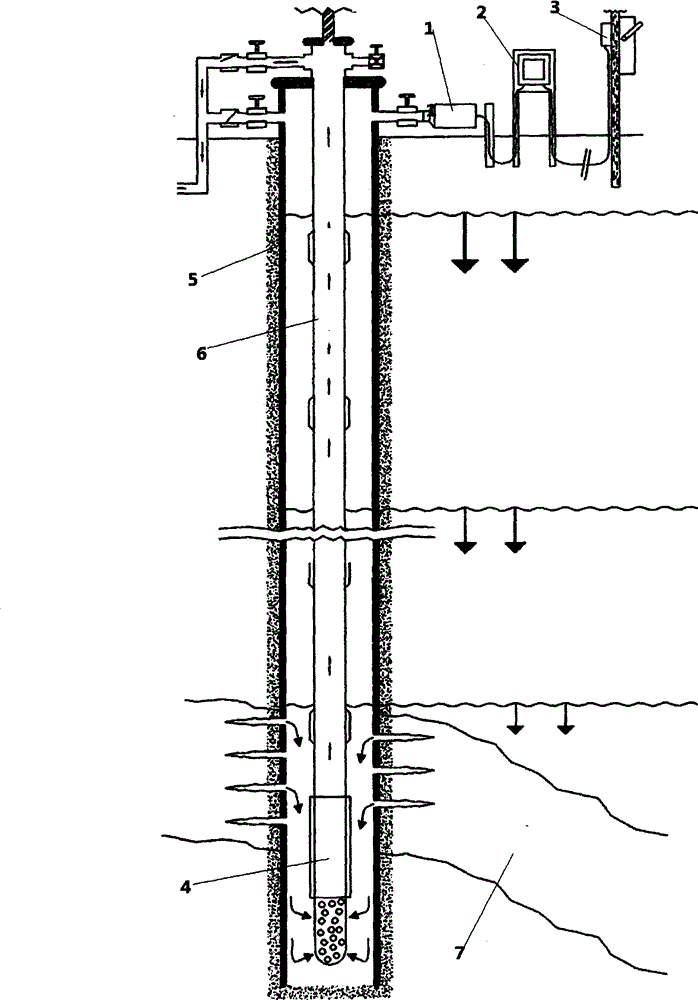

[0015] figure 1 It shows a schematic diagram of the device capable of automatically adjusting the oil discharge capacity of the lifting system of the present invention when it is used for oil well recovery. Such as figure 1 As shown, the device capable of automatically adjusting the oil discharge capacity of the lifting system includes a sound wave generating and receiving mechanism 1 , a control mechanism 2 and a motor distribution box 3 . Wherein, the sound wave generating and receiving mechanism 1 is responsible for emitting sound wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com